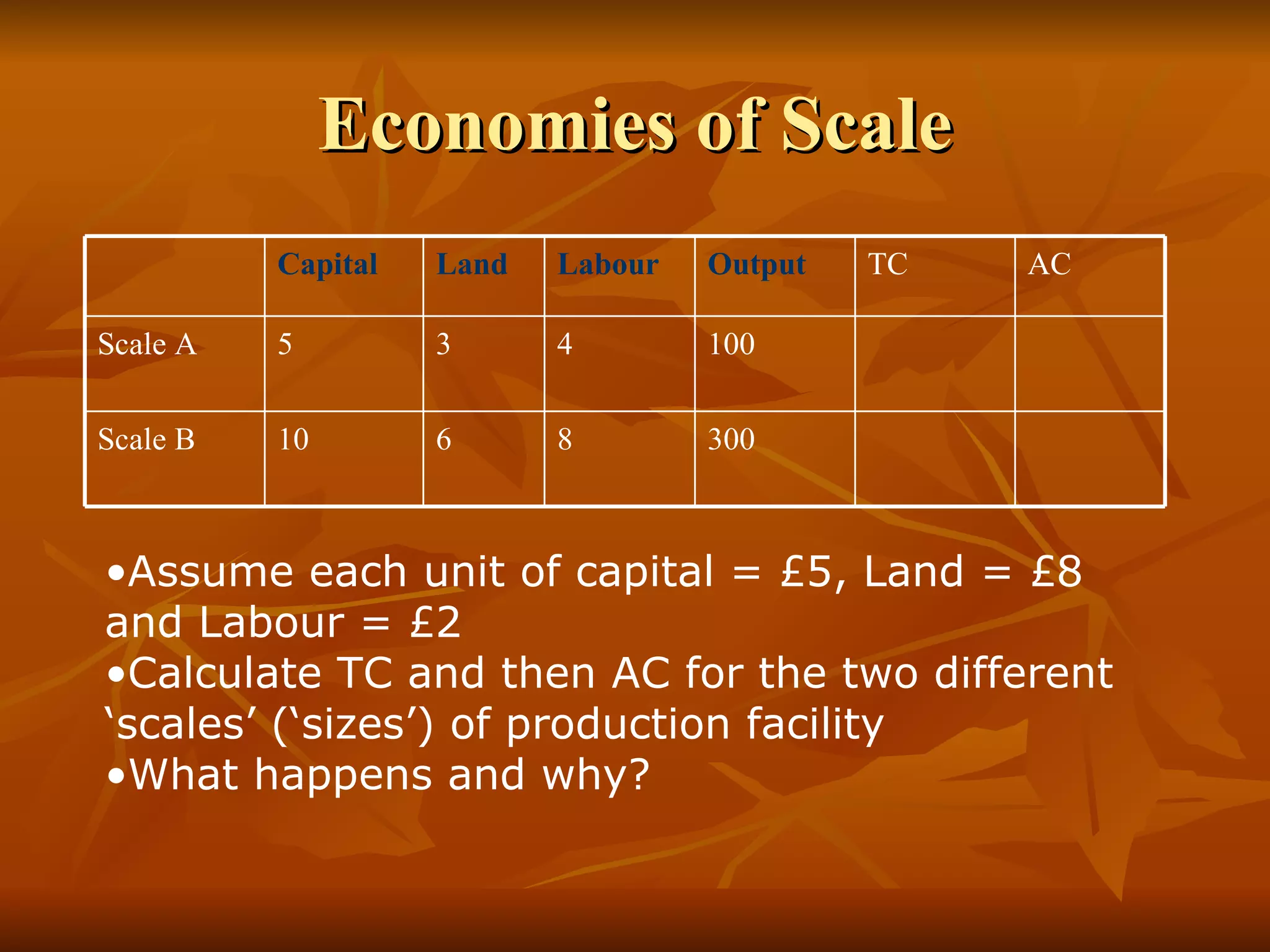

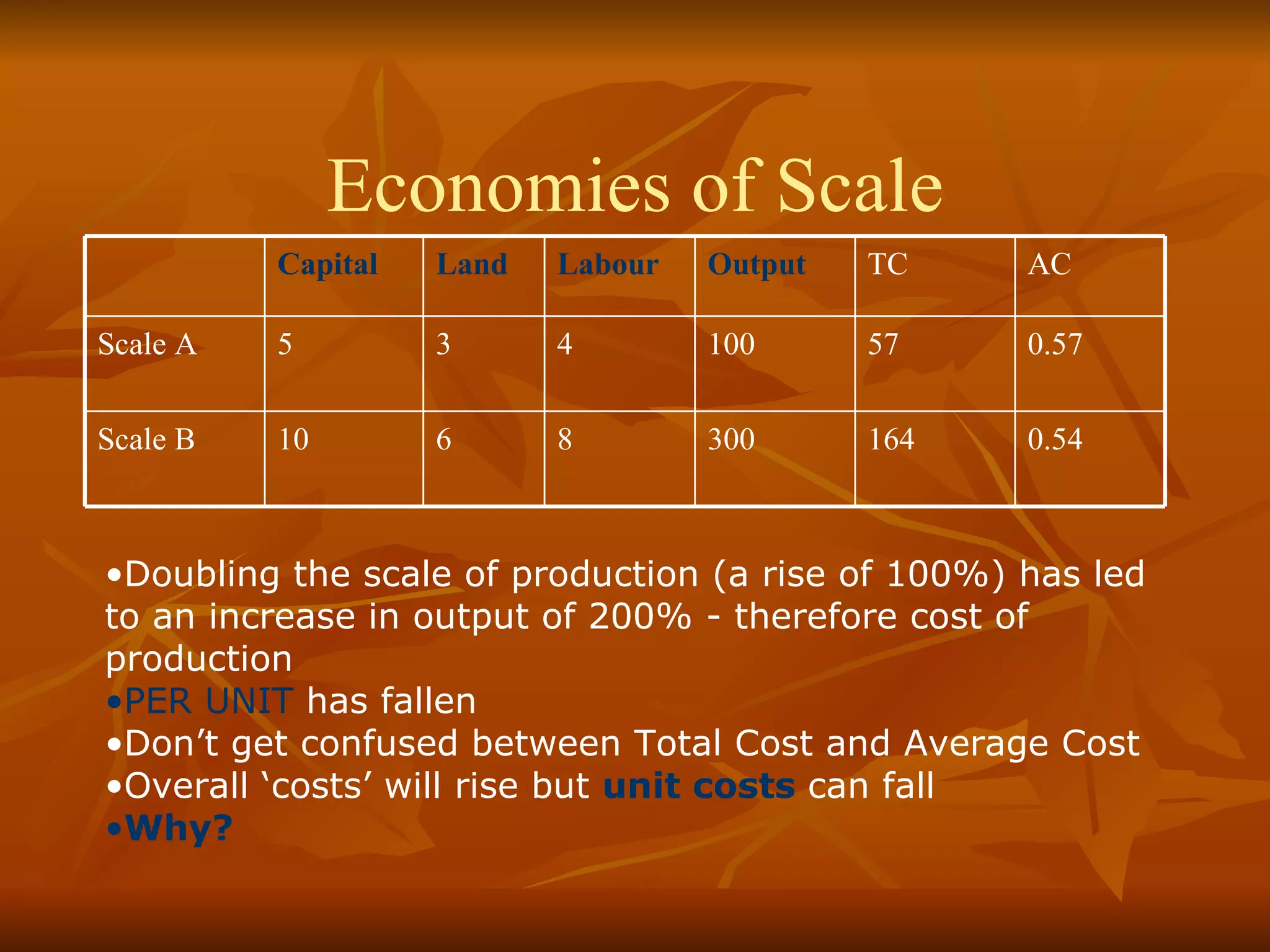

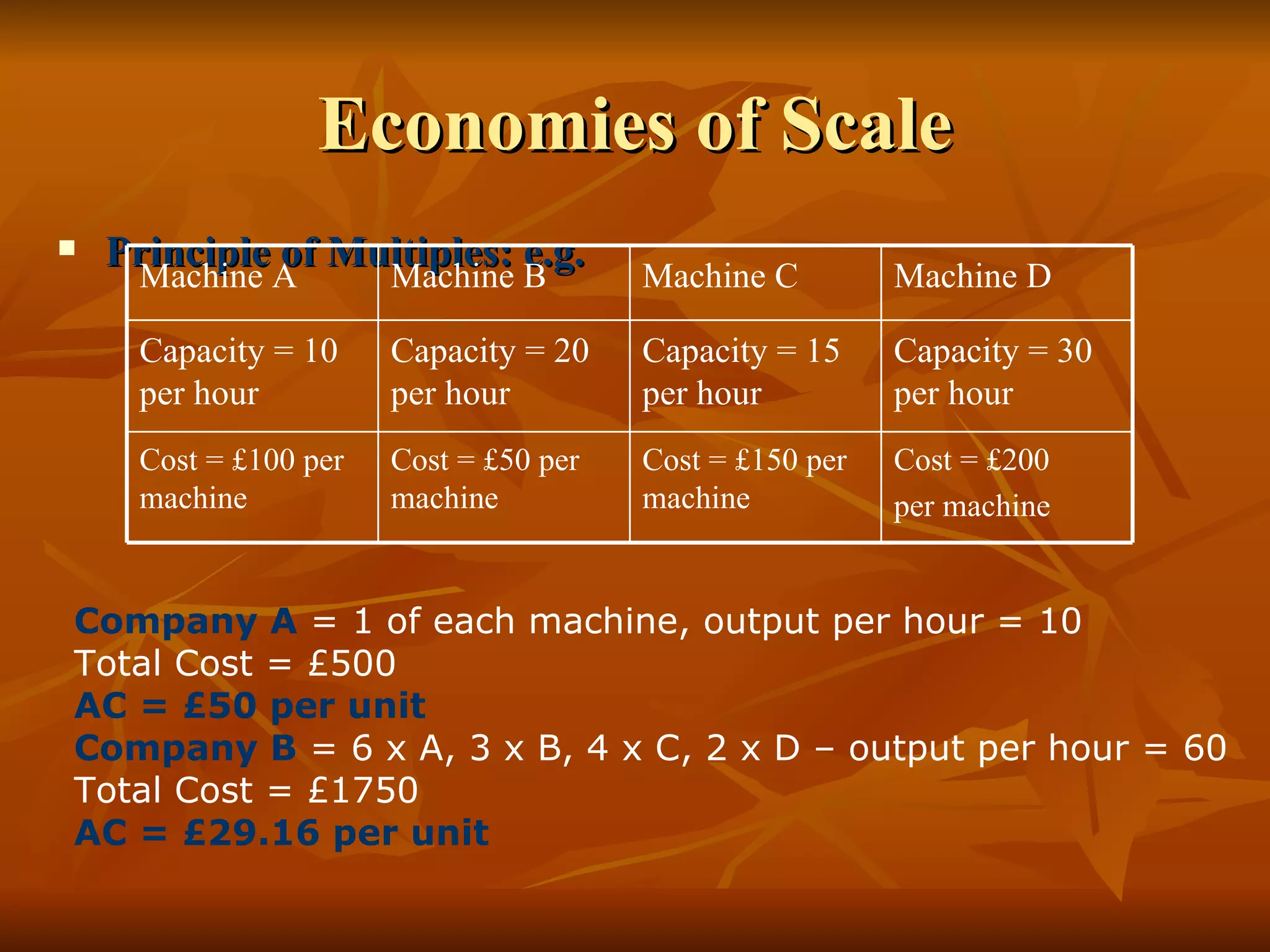

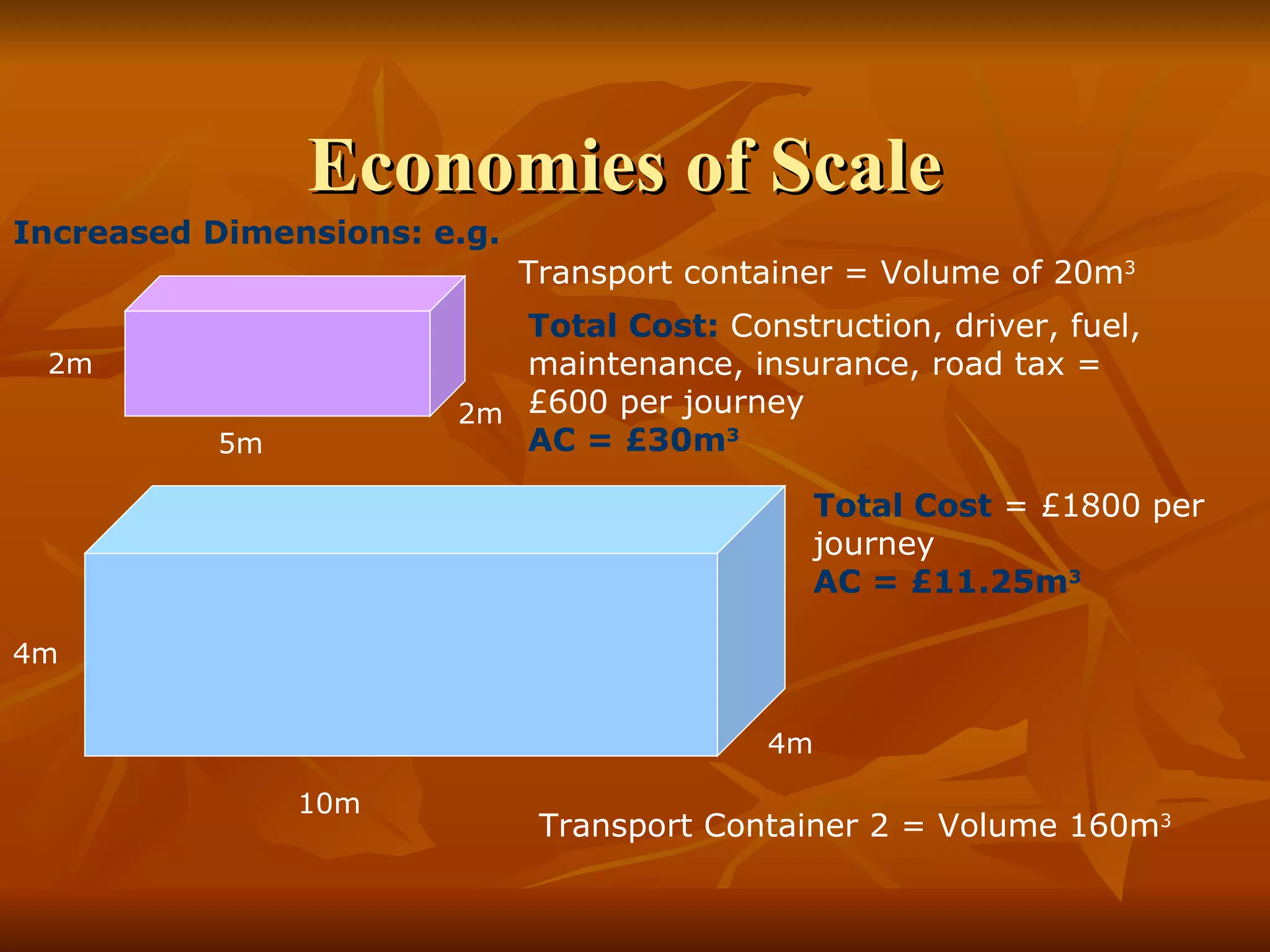

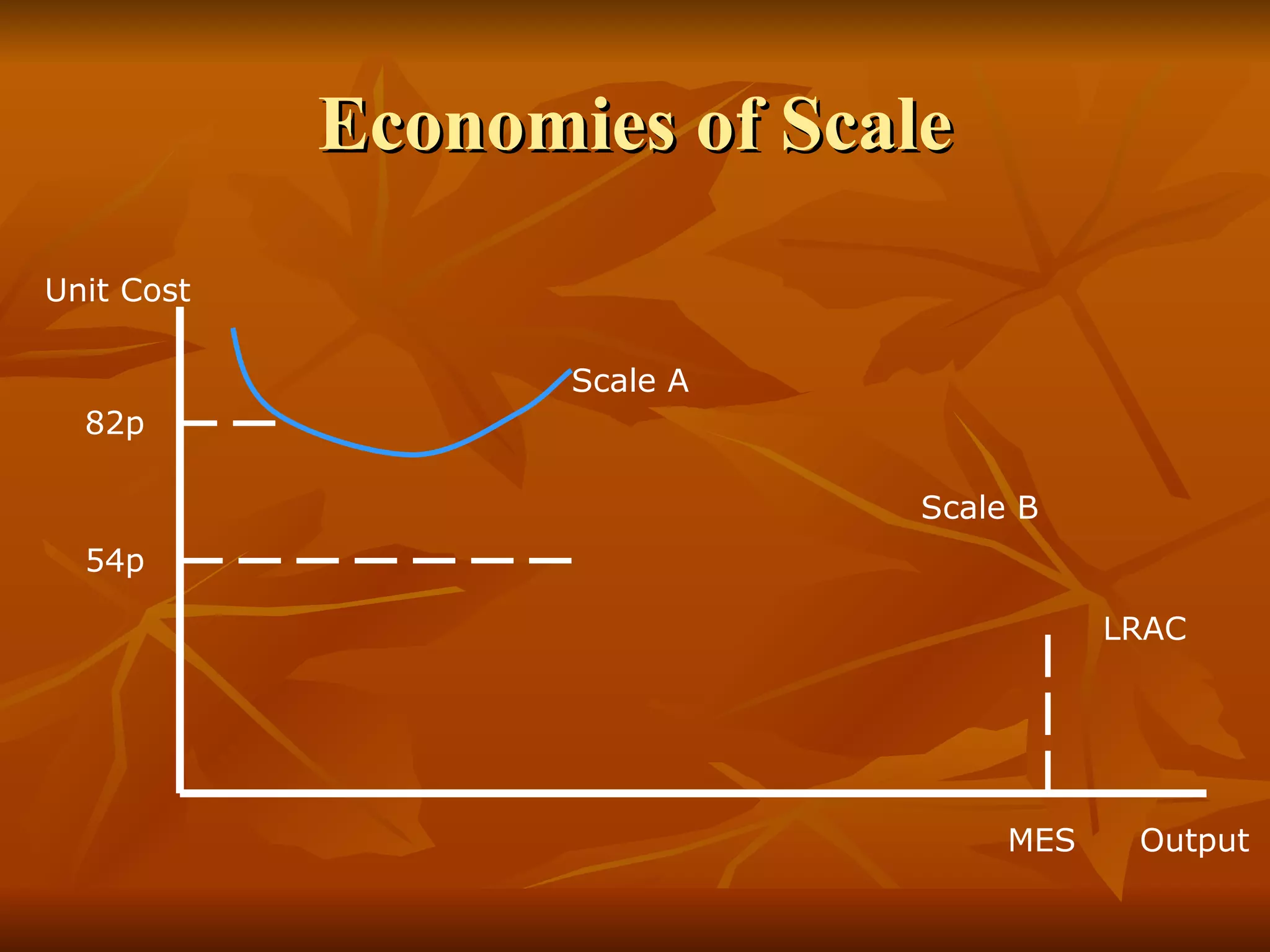

Economies of scale refer to the cost advantages that enterprises can achieve due to growth and increased output. There are two types of economies of scale: internal, which arise from inside the firm due to factors like specialization and use of optimized equipment, and external, which come from industry growth like access to suppliers and infrastructure. As firms increase production, their total costs may rise but average costs per unit can fall due to spreading fixed costs over more units. This is illustrated through an example where doubling scale leads to a 200% output increase but a lower average cost per unit.