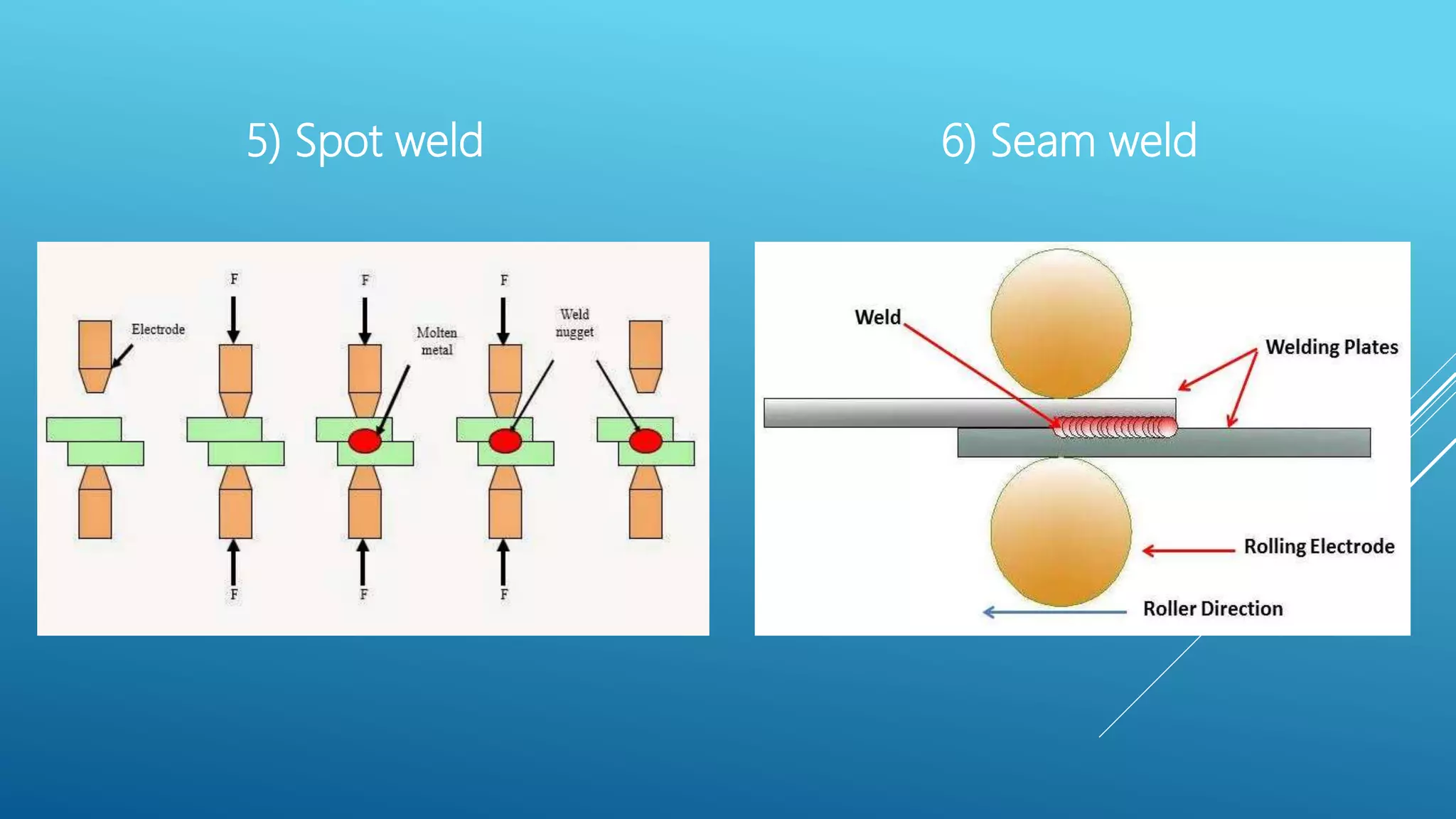

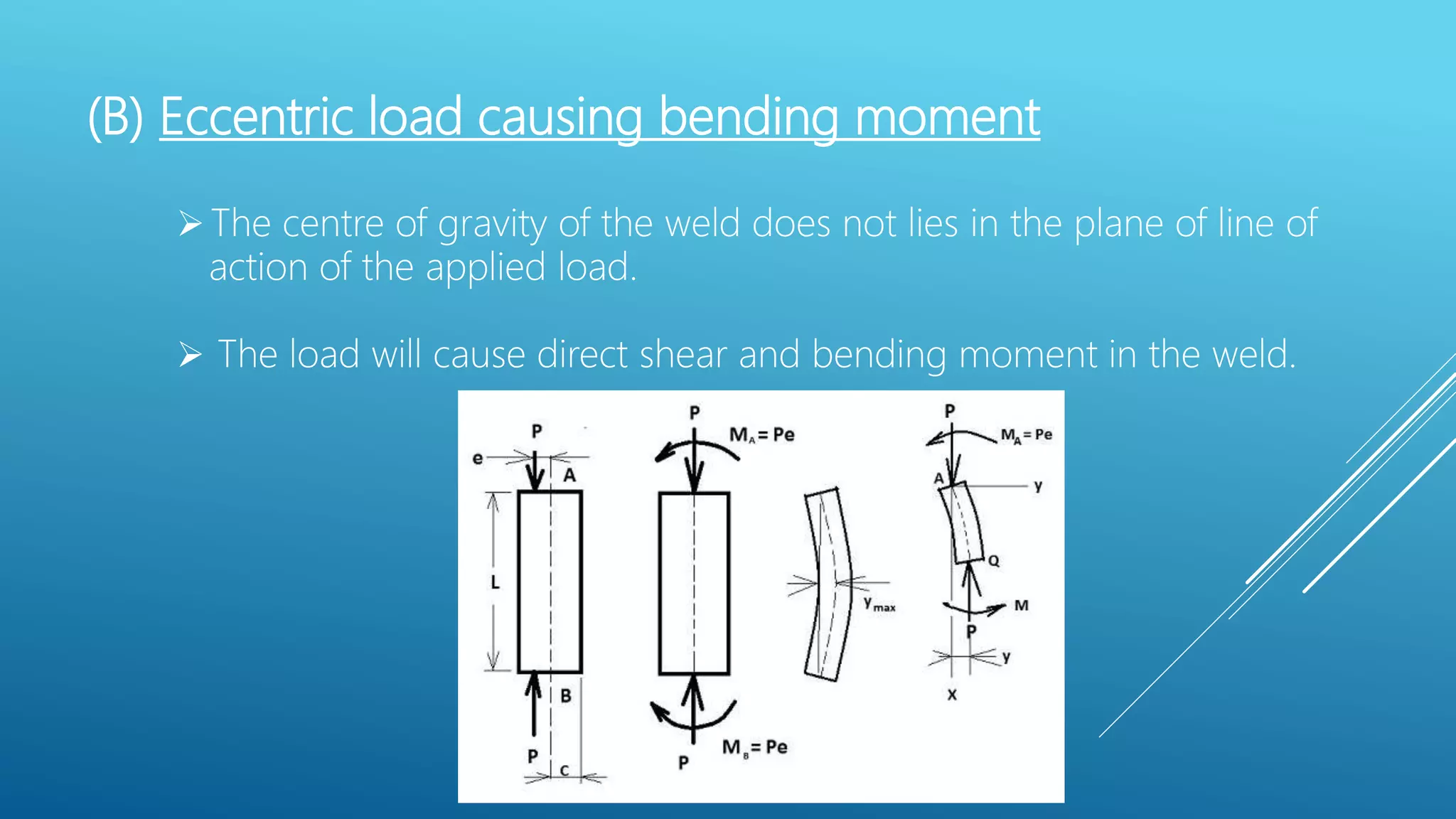

The document presents a presentation on the topic of eccentric load in plane of welds within mechanical engineering. It covers the welding process, various types of welds, and specifically addresses eccentric loads that do not act along the central axis of structural members, distinguishing between those causing twisting and bending moments. The presentation emphasizes the implications of eccentric loading on the integrity of welds.