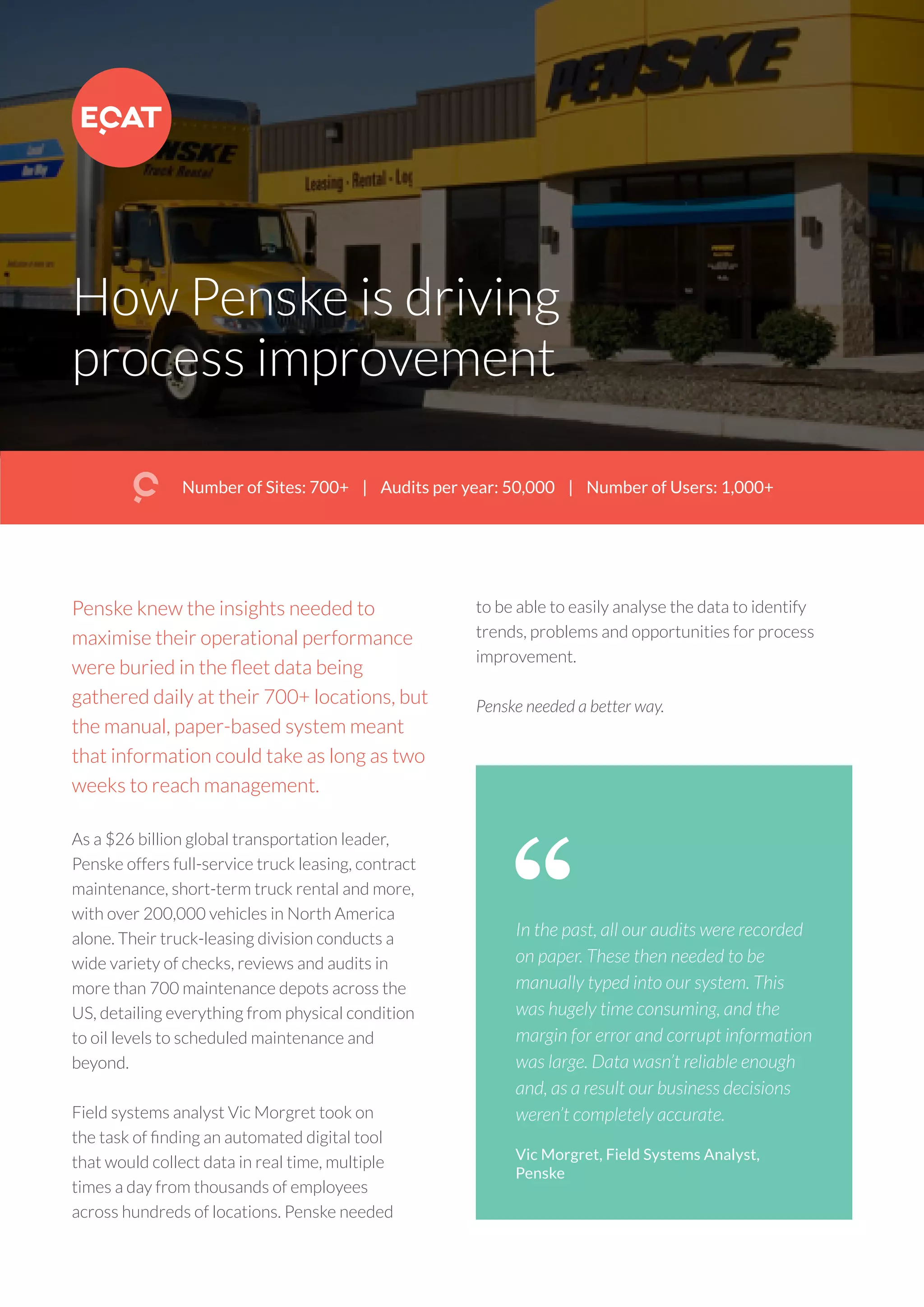

Penske, a $26 billion transportation company, needed a better system to collect inspection data from its 700+ locations to identify operational issues and opportunities for improvement. The previous paper-based system took up to two weeks to provide information to management. Penske implemented an inspection management software called ECAT to digitally collect real-time data multiple times per day from 1,000+ employees. This new system reduced the audit process from 10 hours to 2 hours and provided instant data analysis to help Penske standardize processes and improve operations.