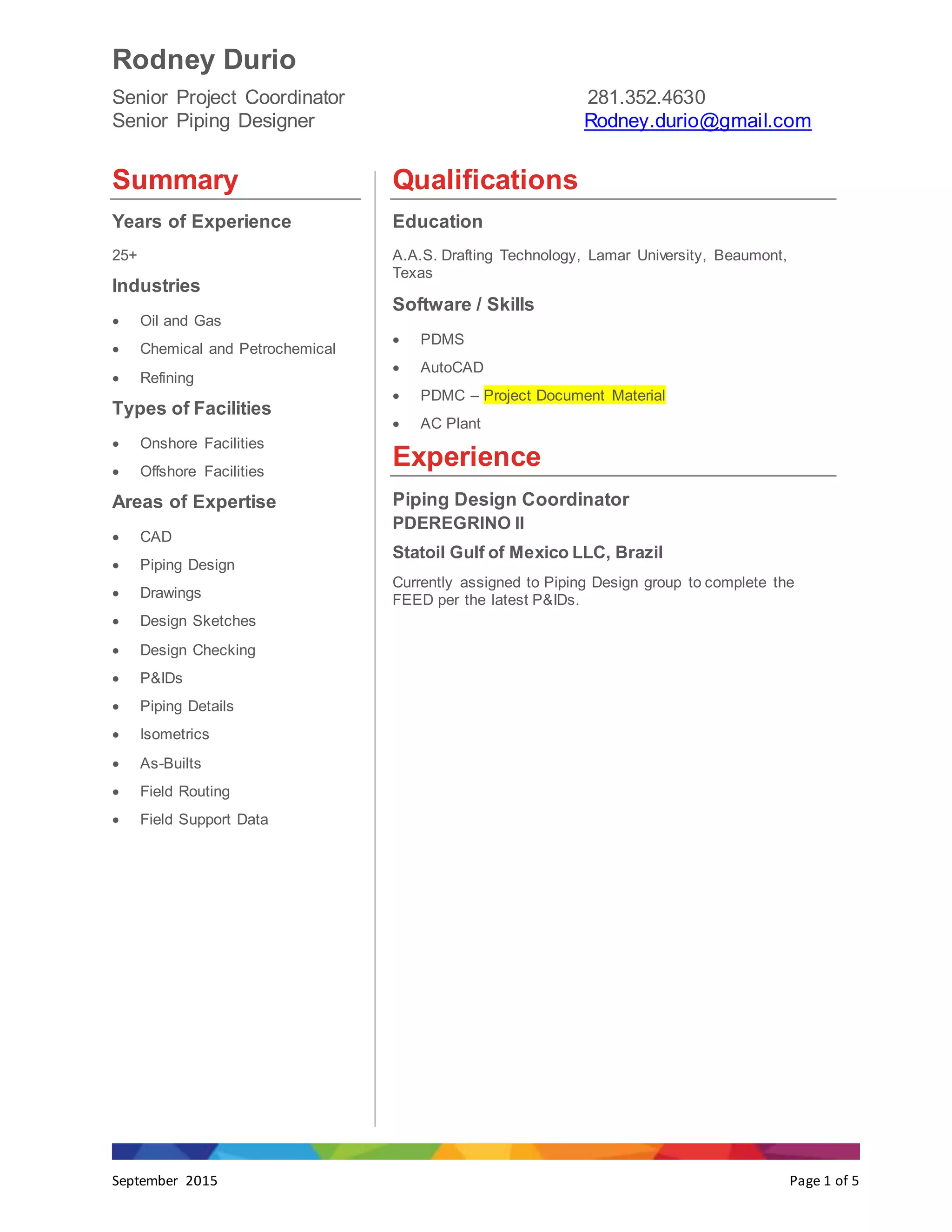

Rodney Durio has over 25 years of experience in piping design for oil and gas, chemical, and refining projects. He has expertise in CAD software like PDMS and AutoCAD. Some of his roles include senior piping designer, project coordinator, and piping design coordinator. He has worked on both offshore and onshore facilities around the world.