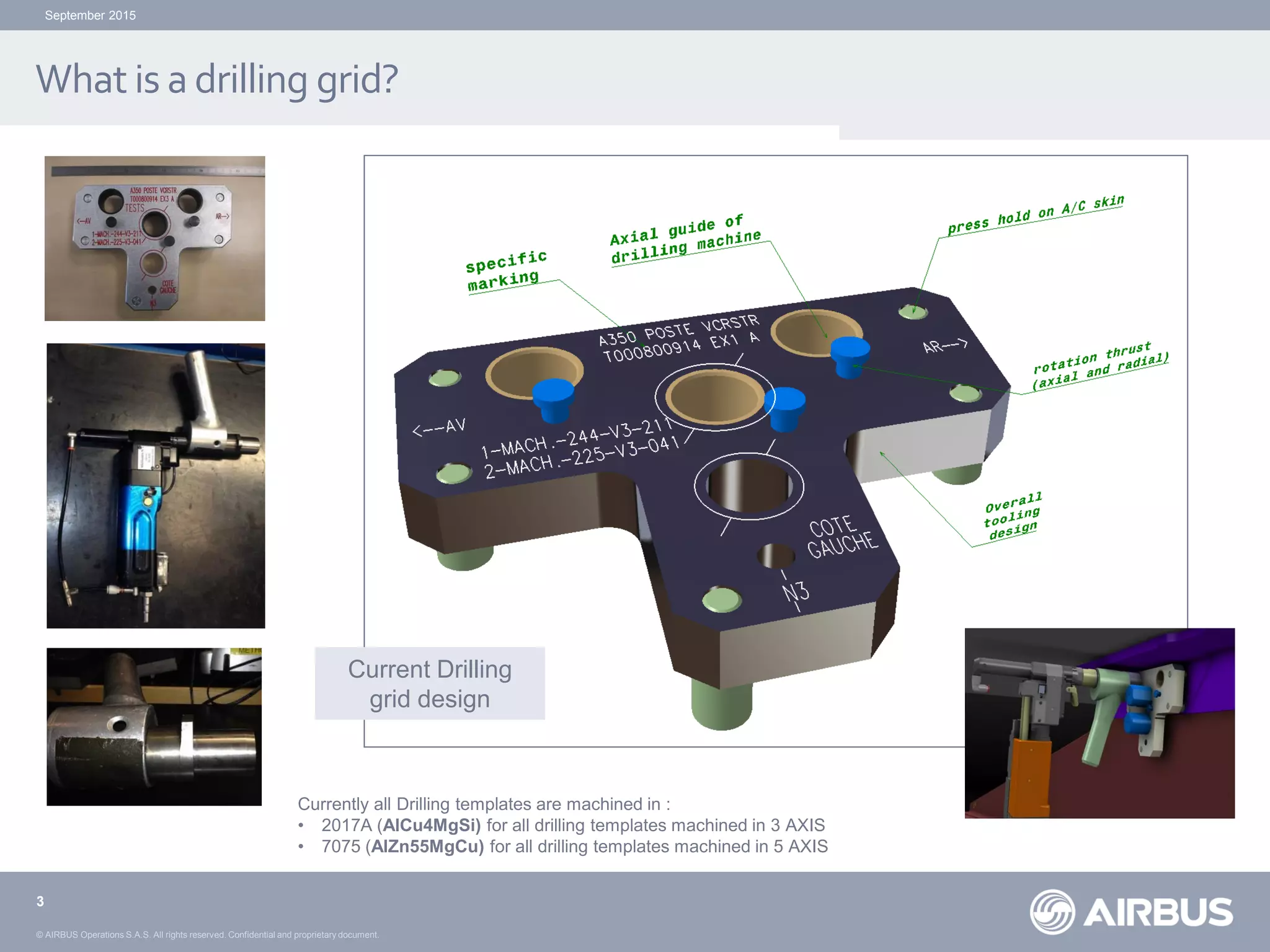

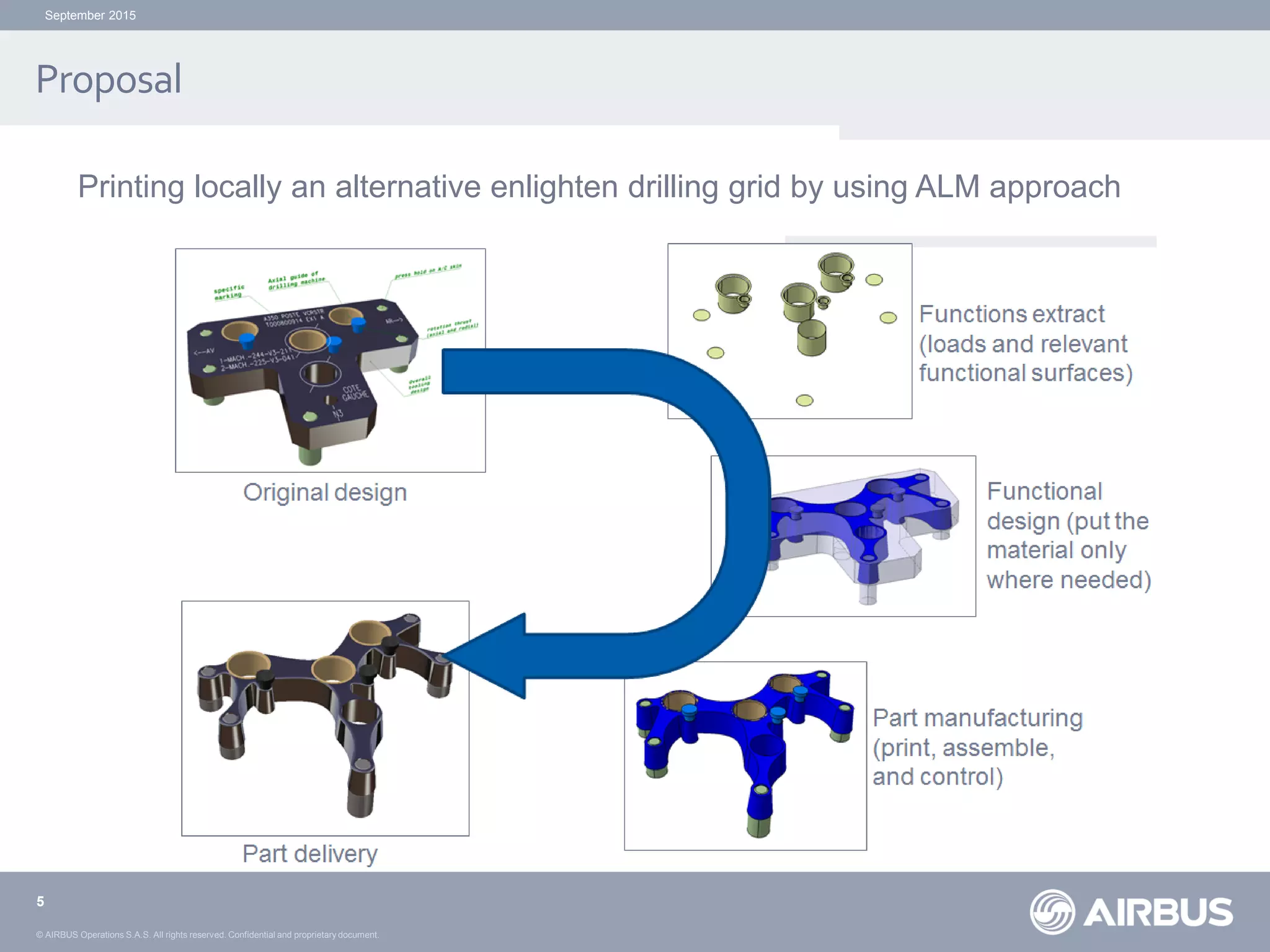

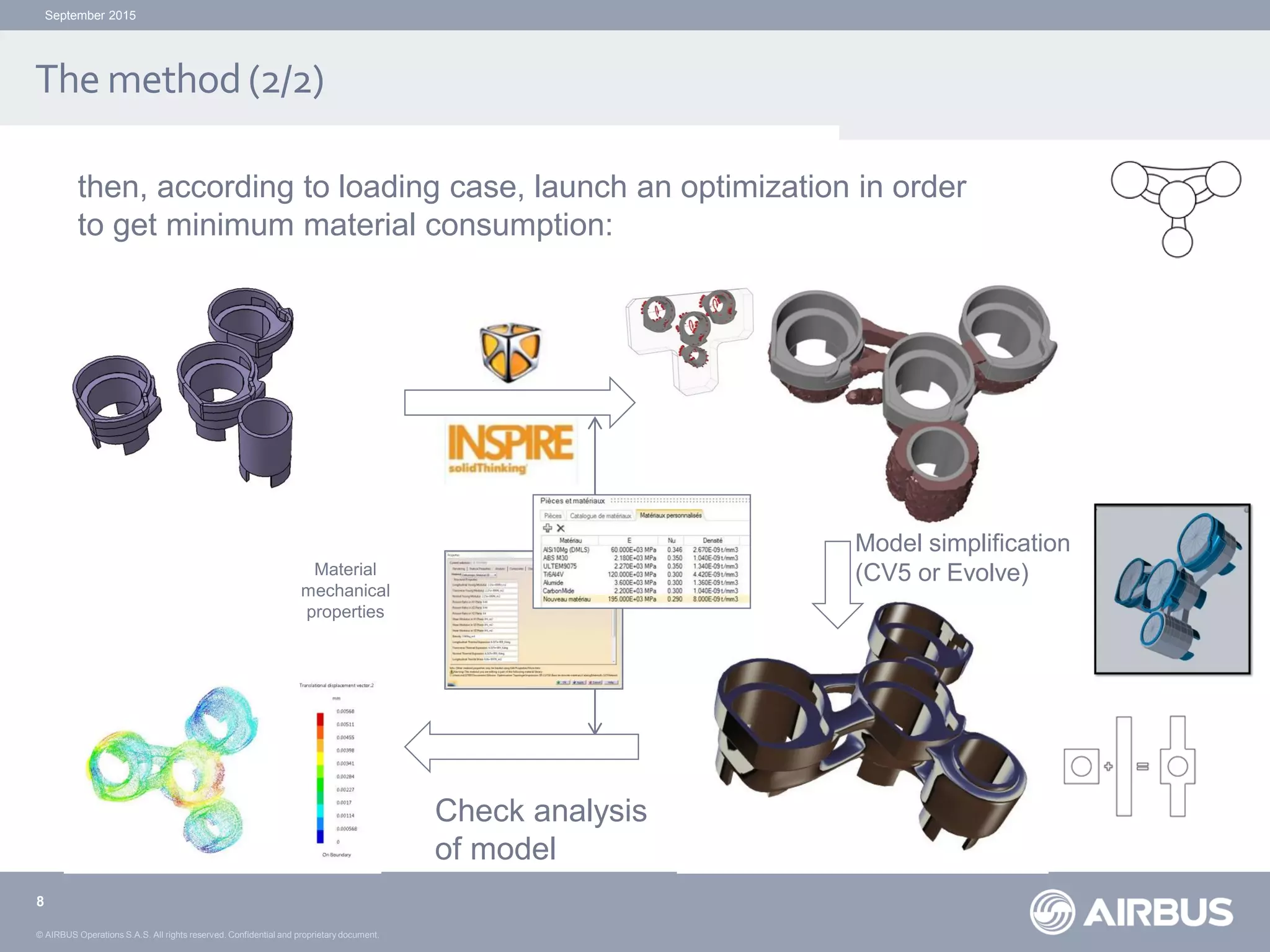

The document discusses the challenges of timely delivery and quality of drilling grids for Airbus's A380 assembly, highlighting the potential of 3D printing and topology optimization as a solution. It proposes using additive layer manufacturing to create lighter, faster, and more efficient drilling templates, significantly reducing production time from 12 weeks to 2 weeks. The method allows for local printing and easier implementation, making it a practical alternative for tooling requests.