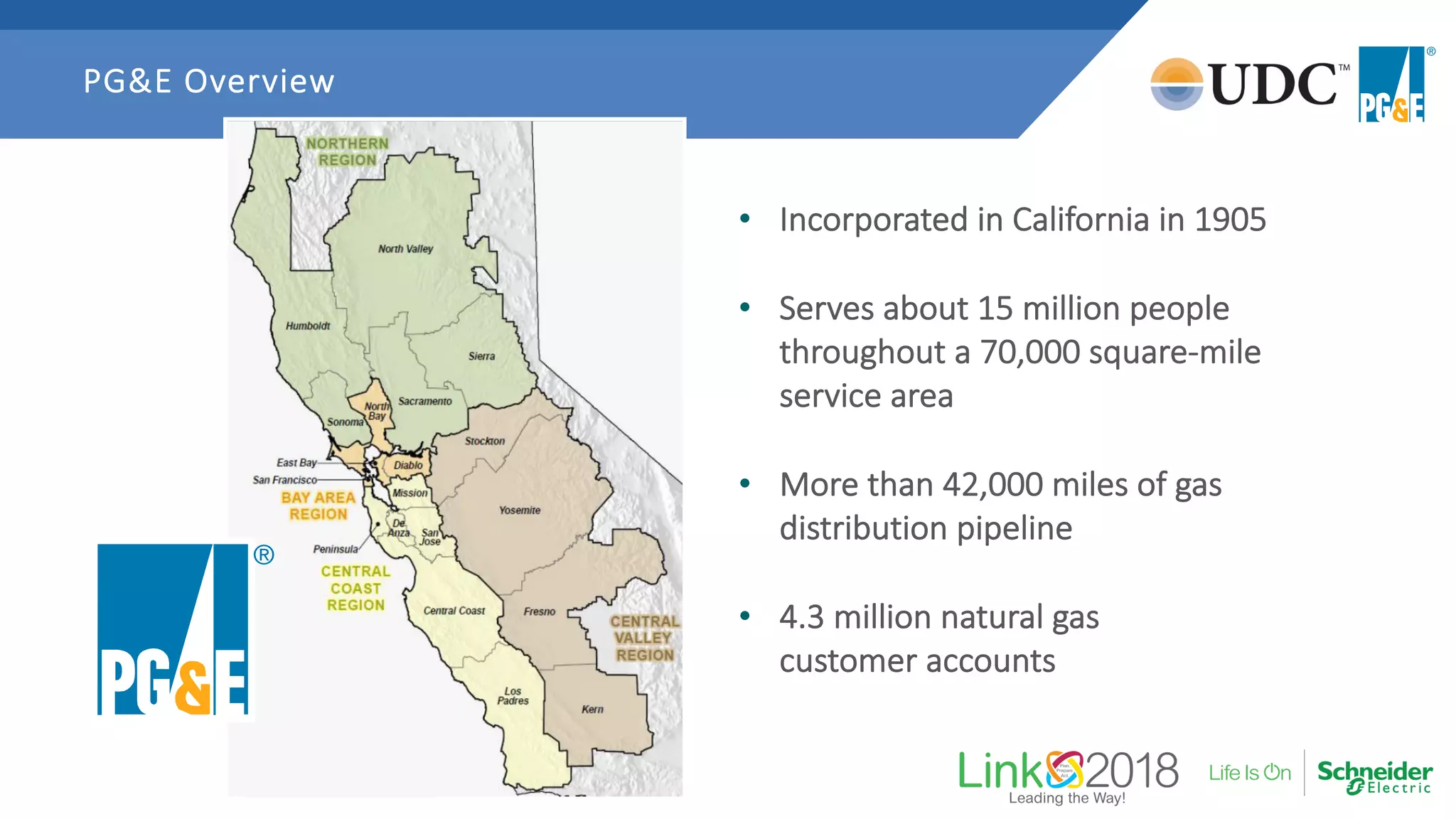

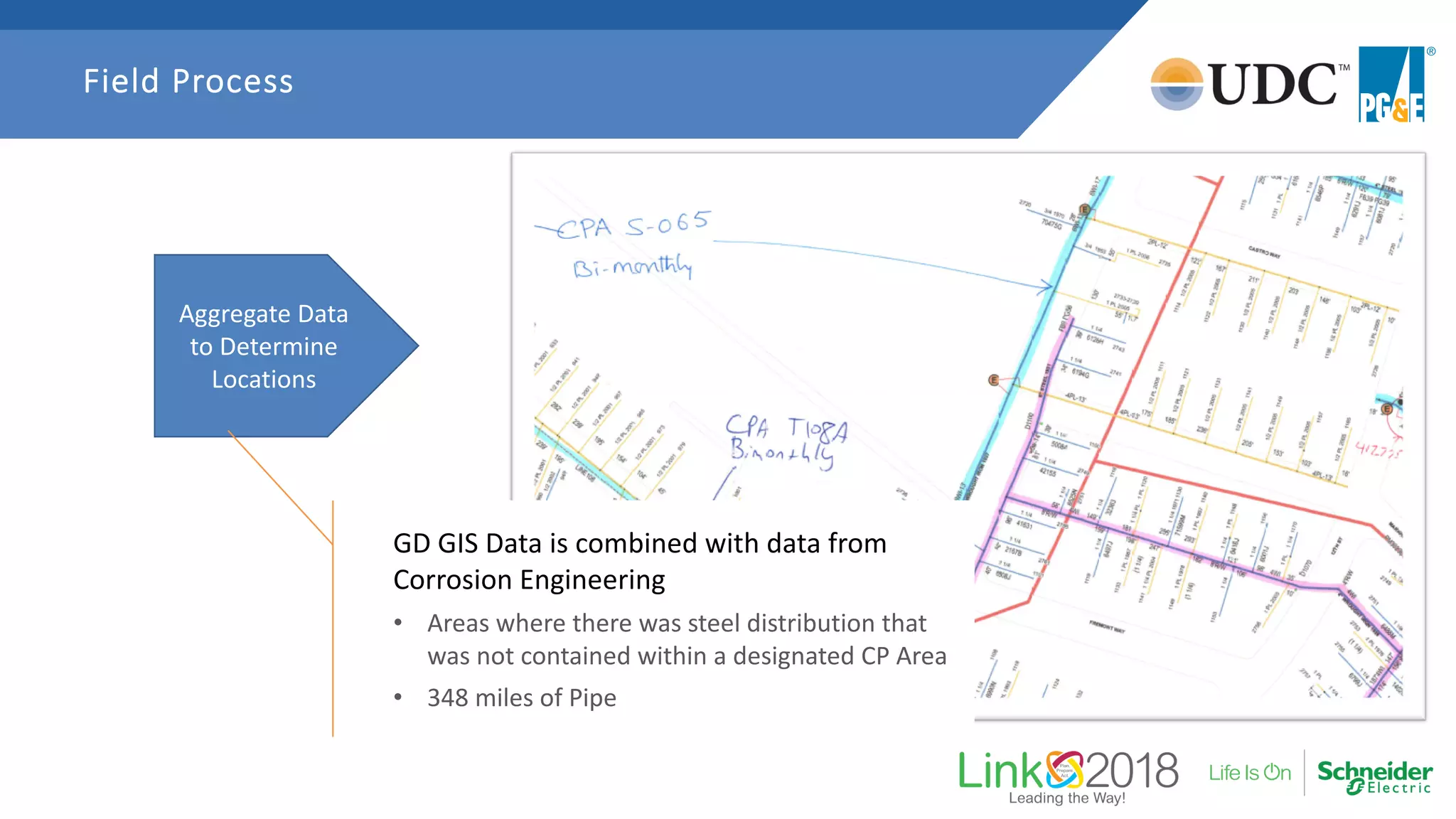

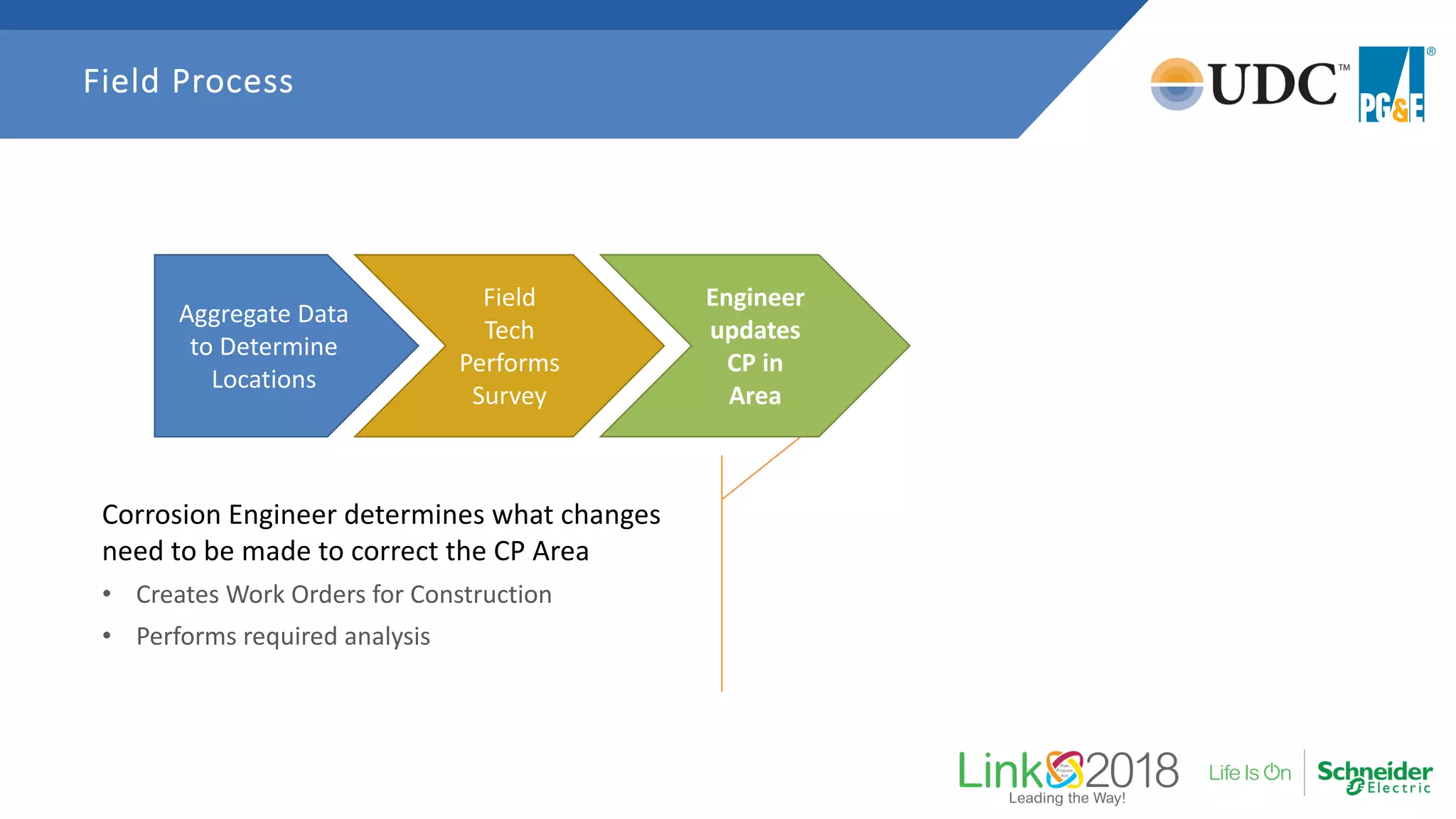

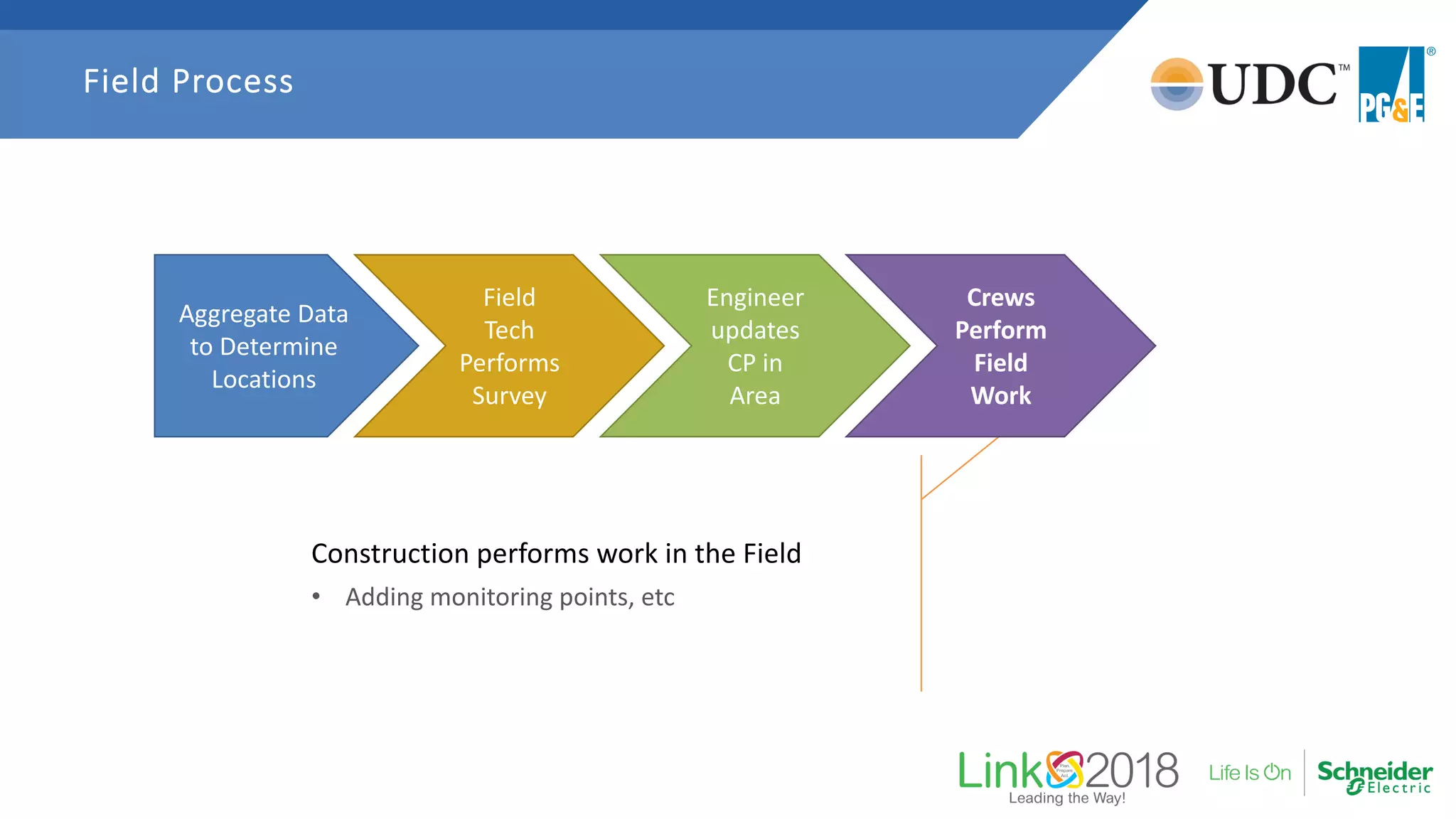

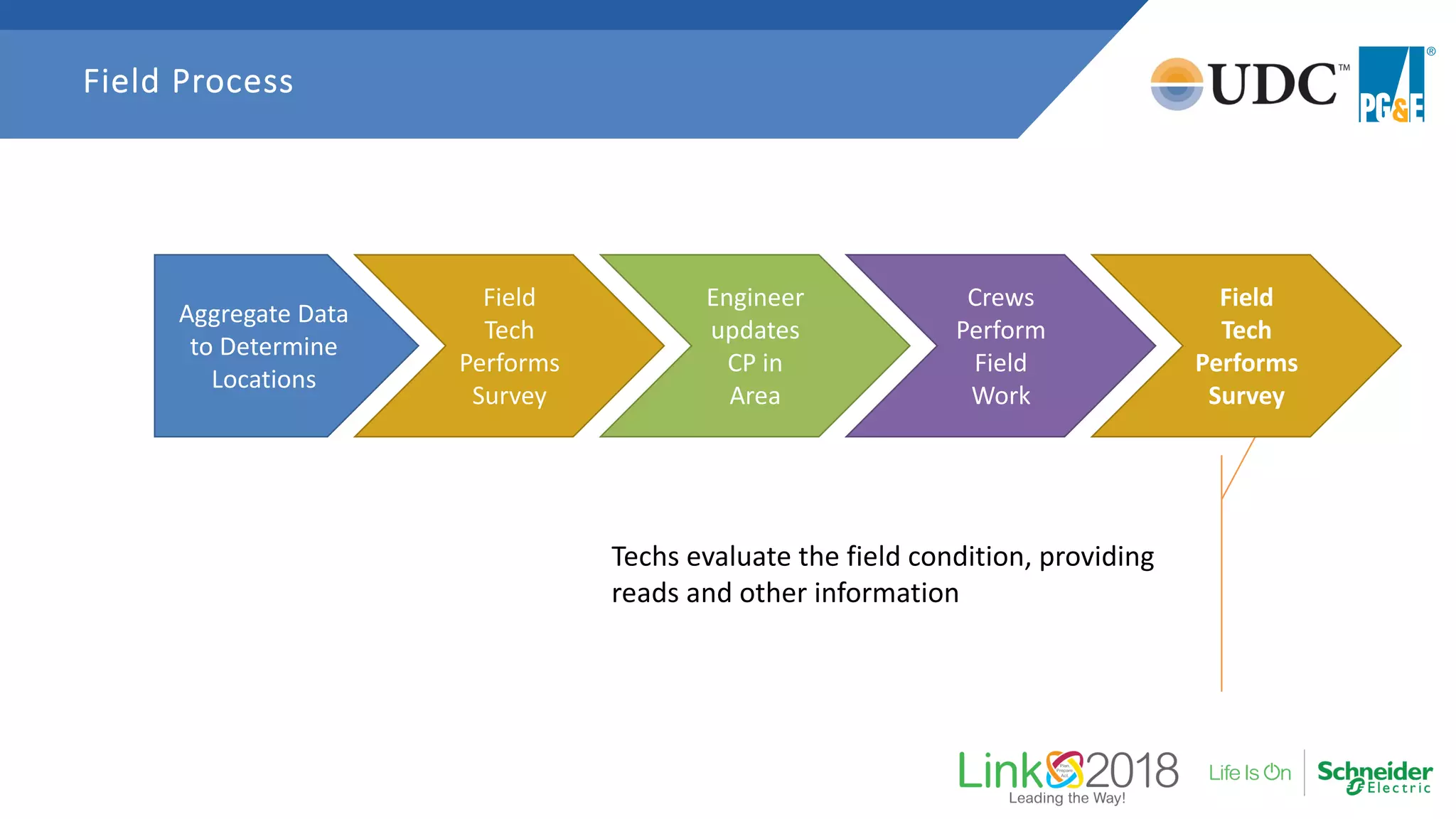

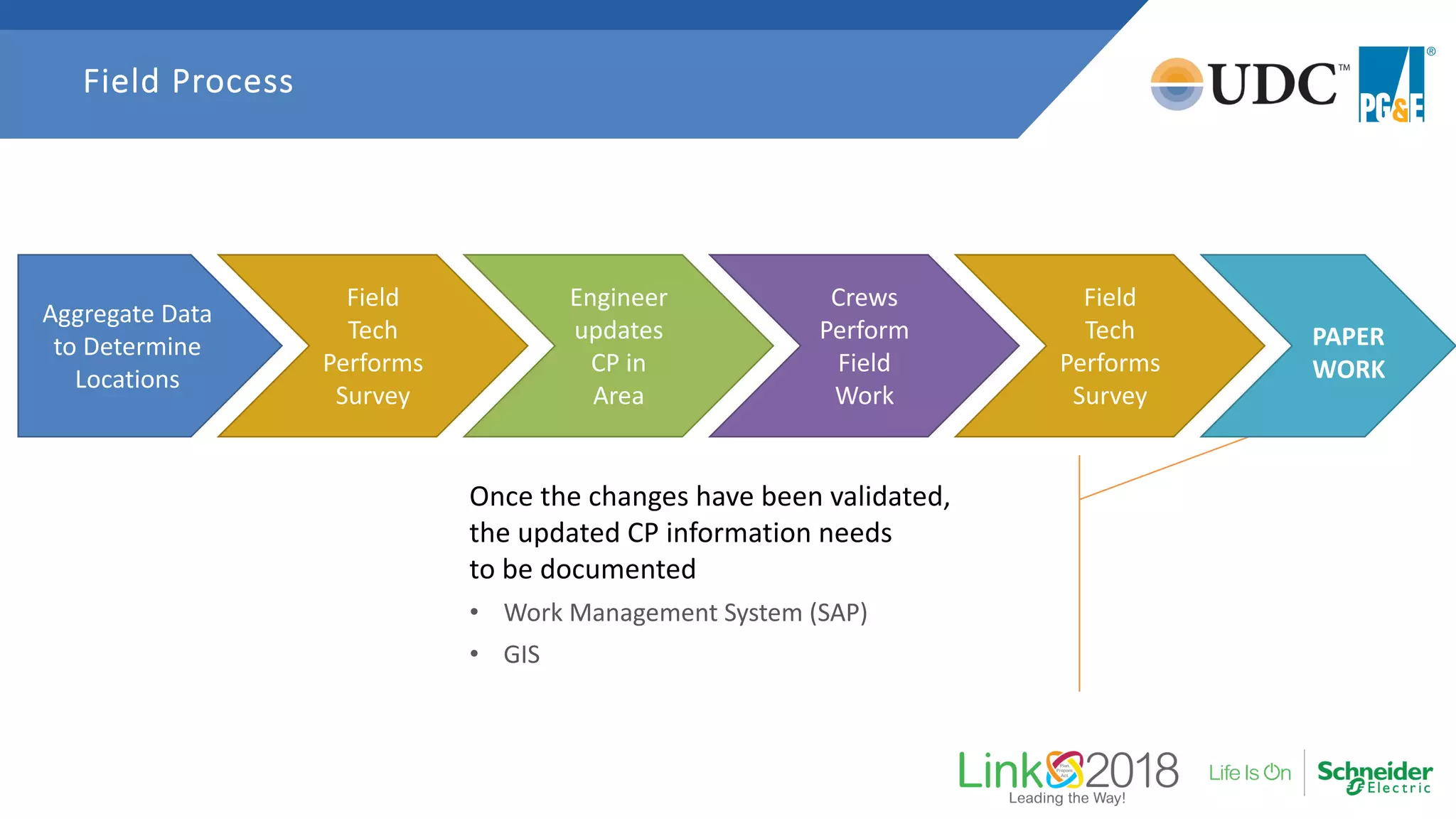

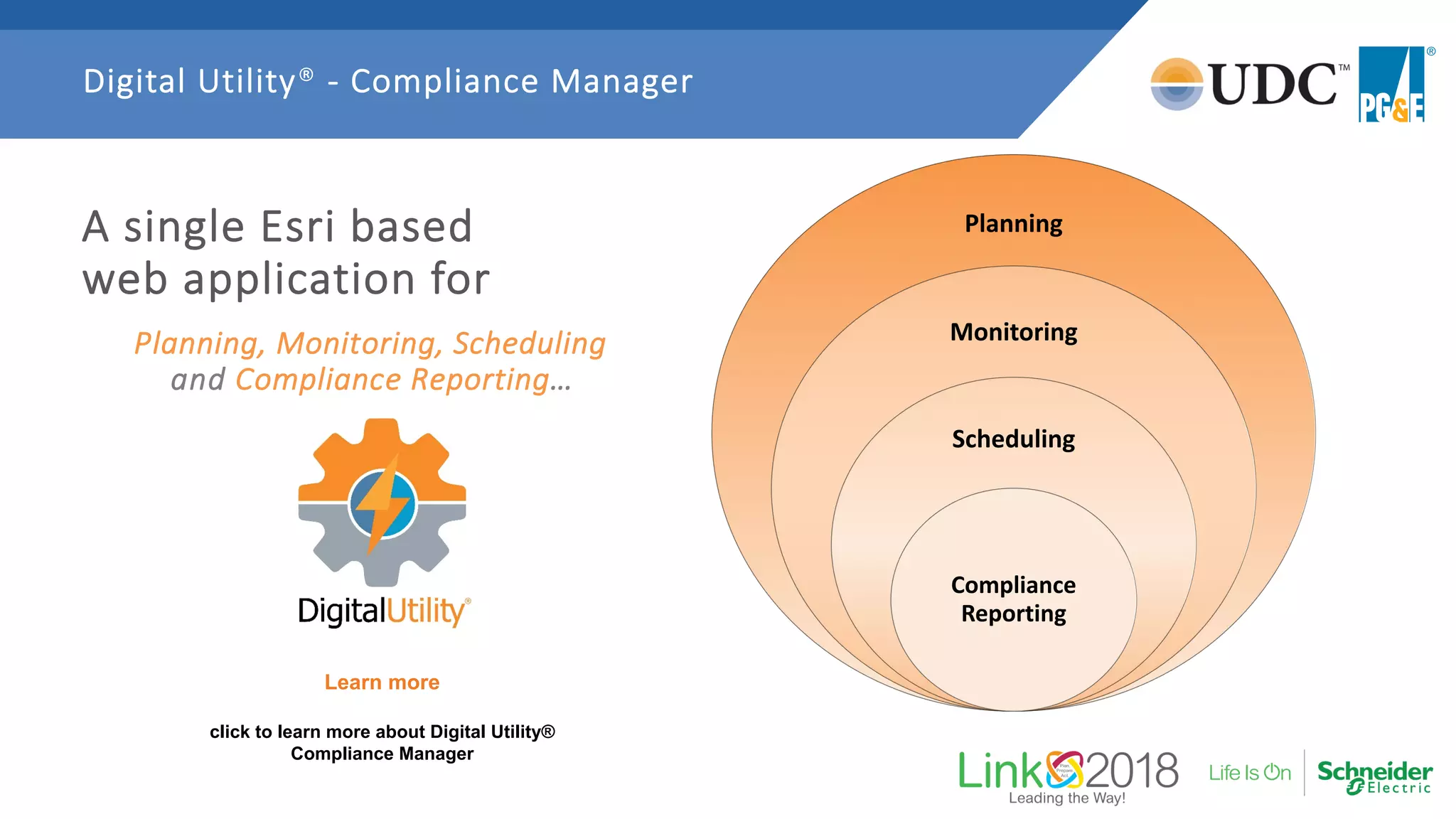

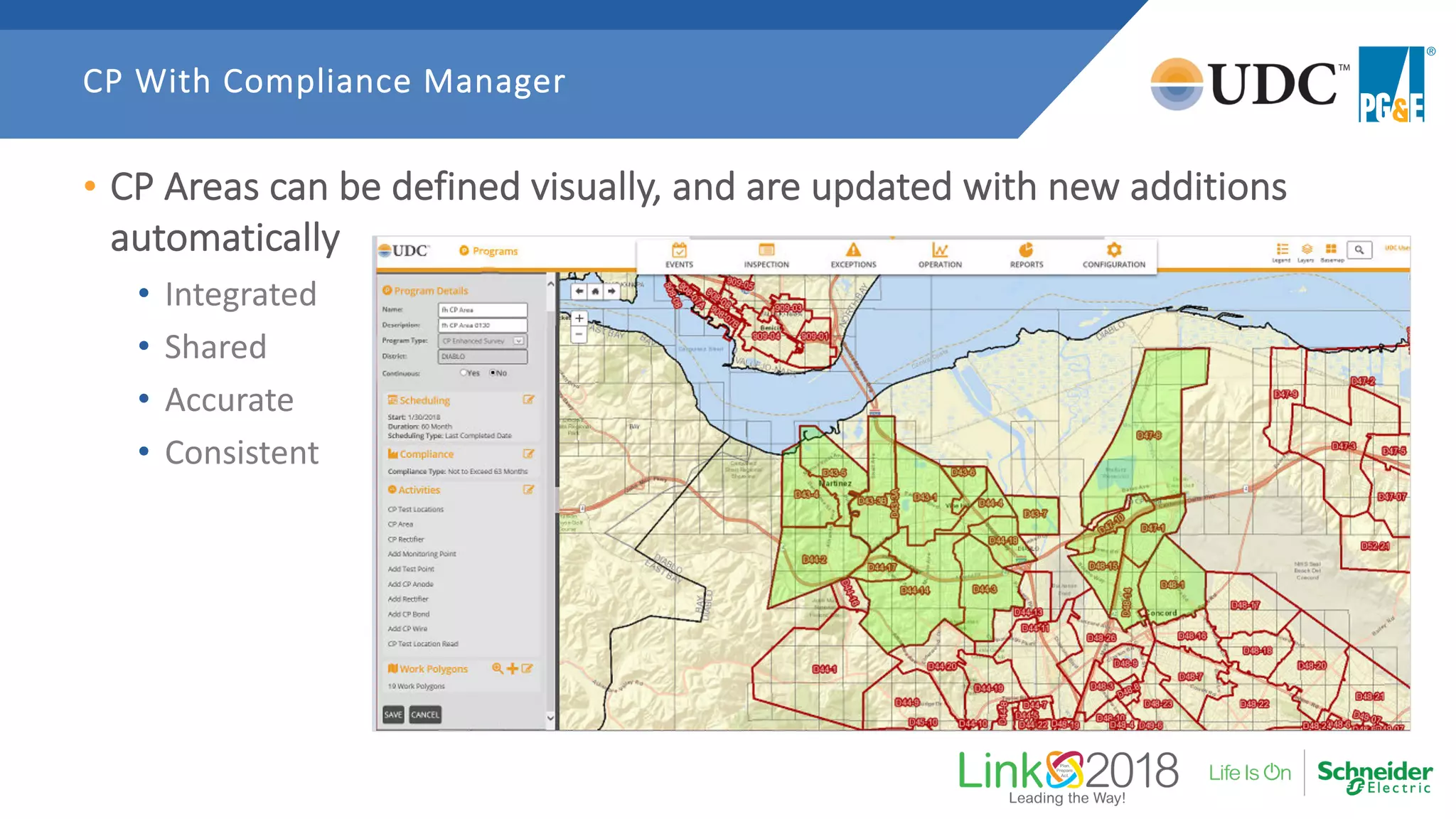

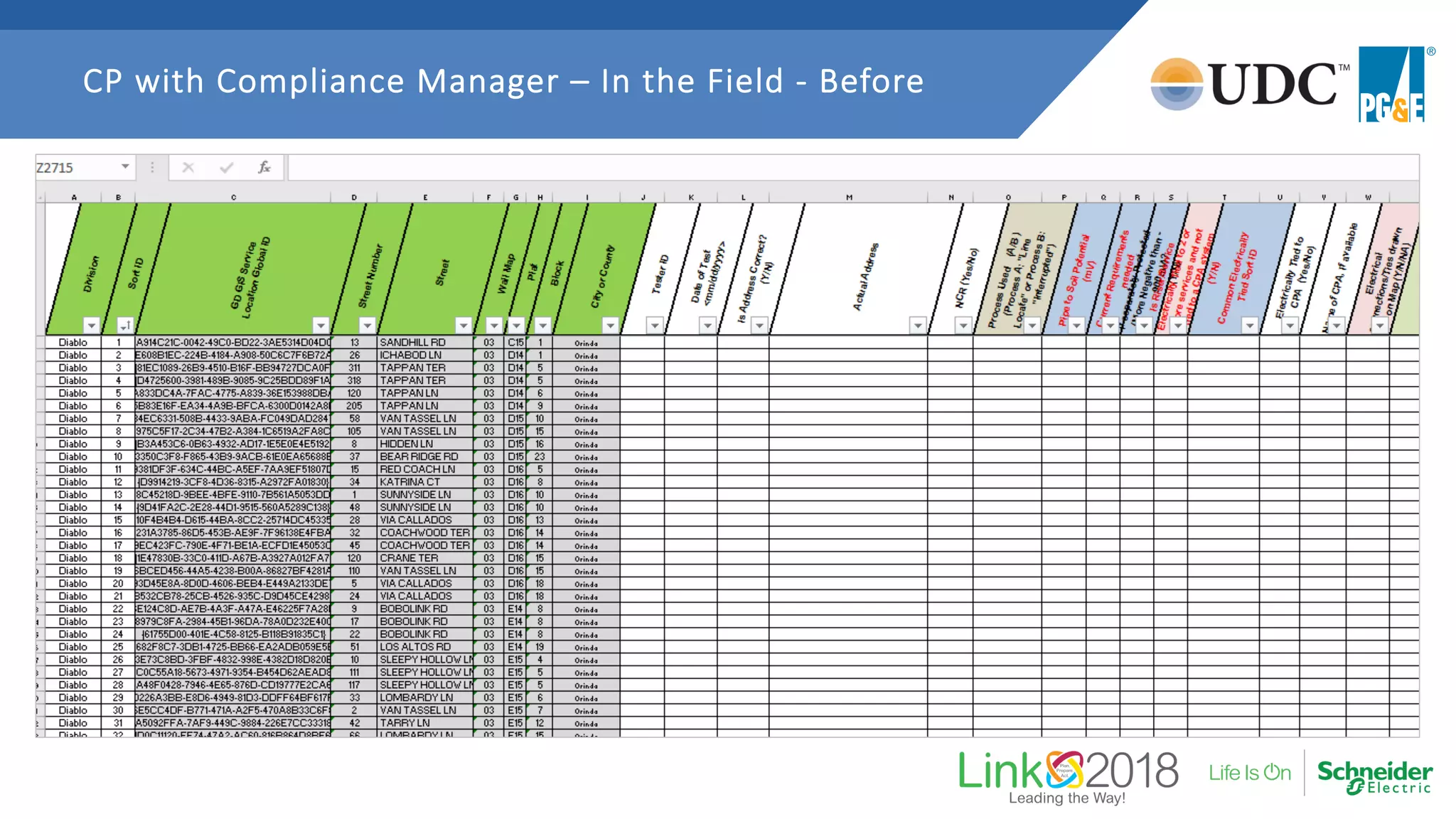

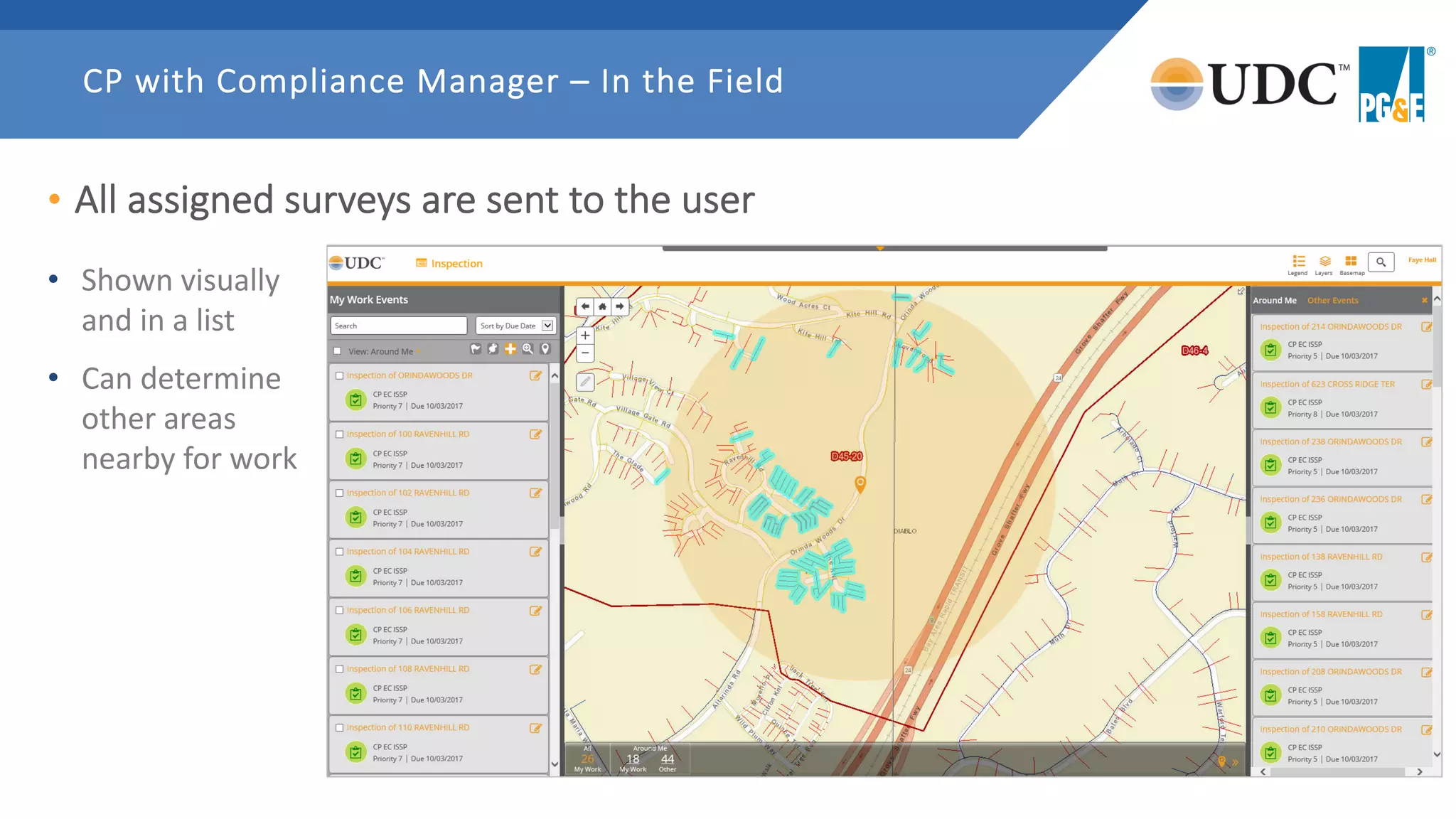

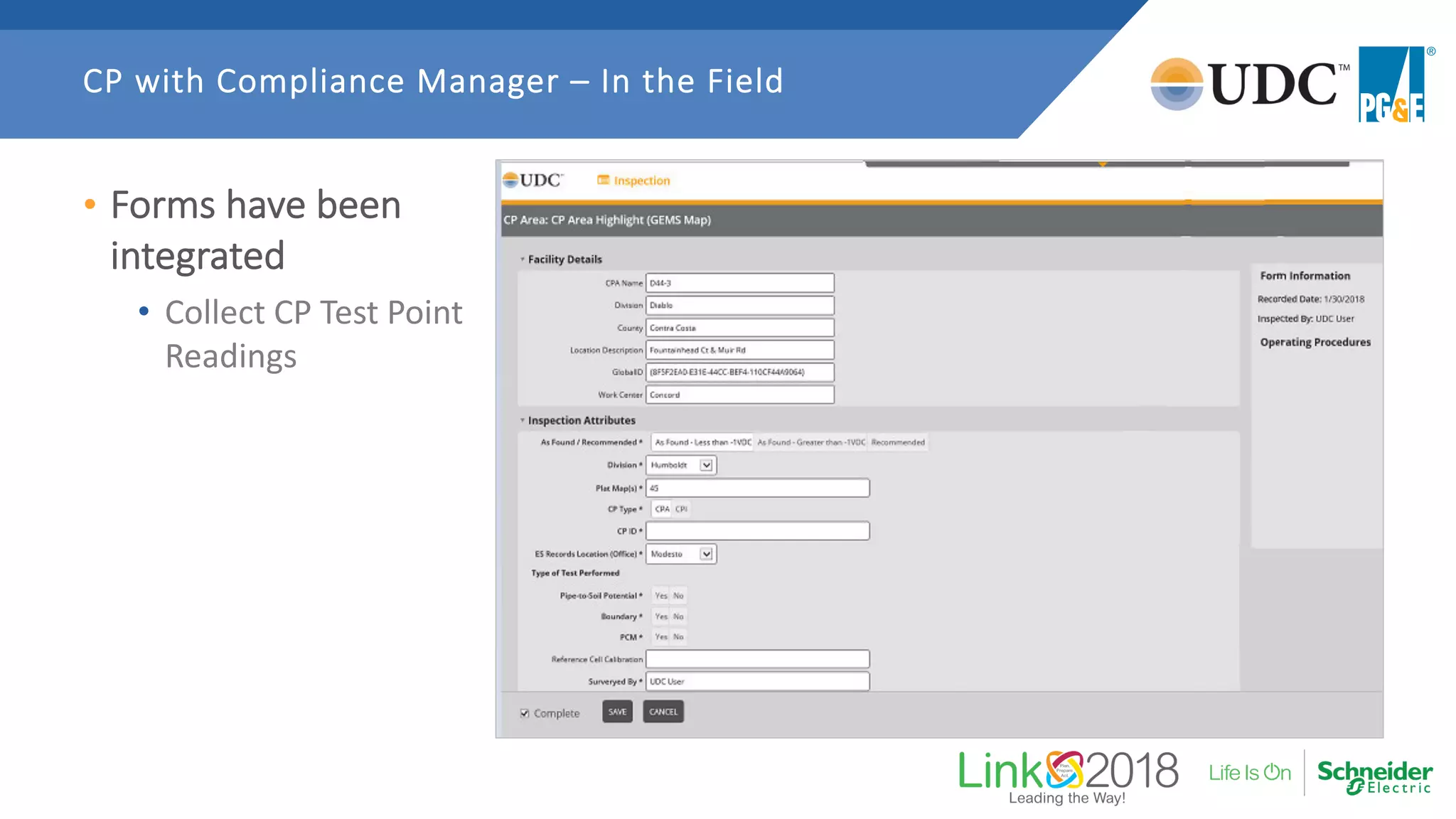

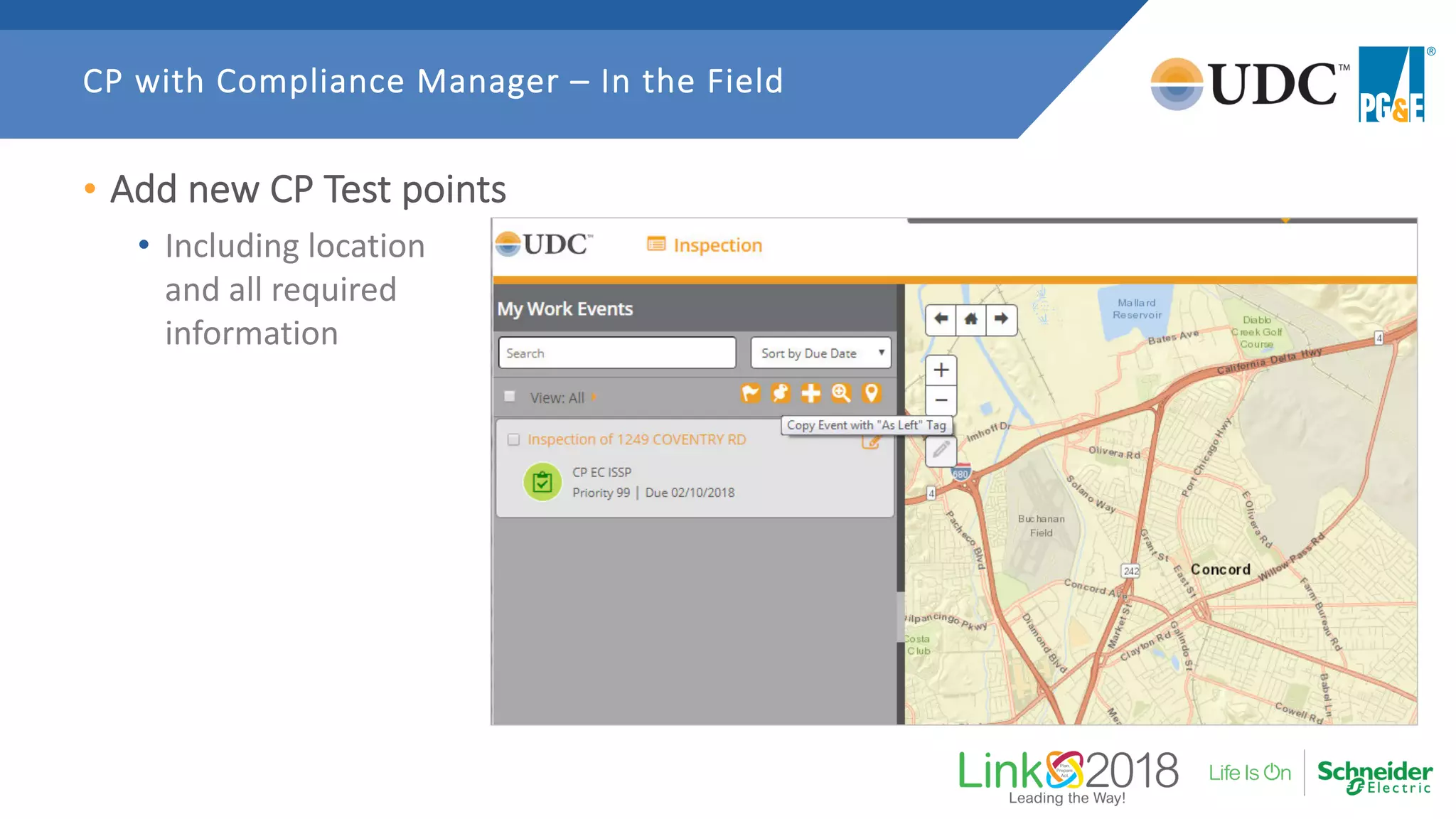

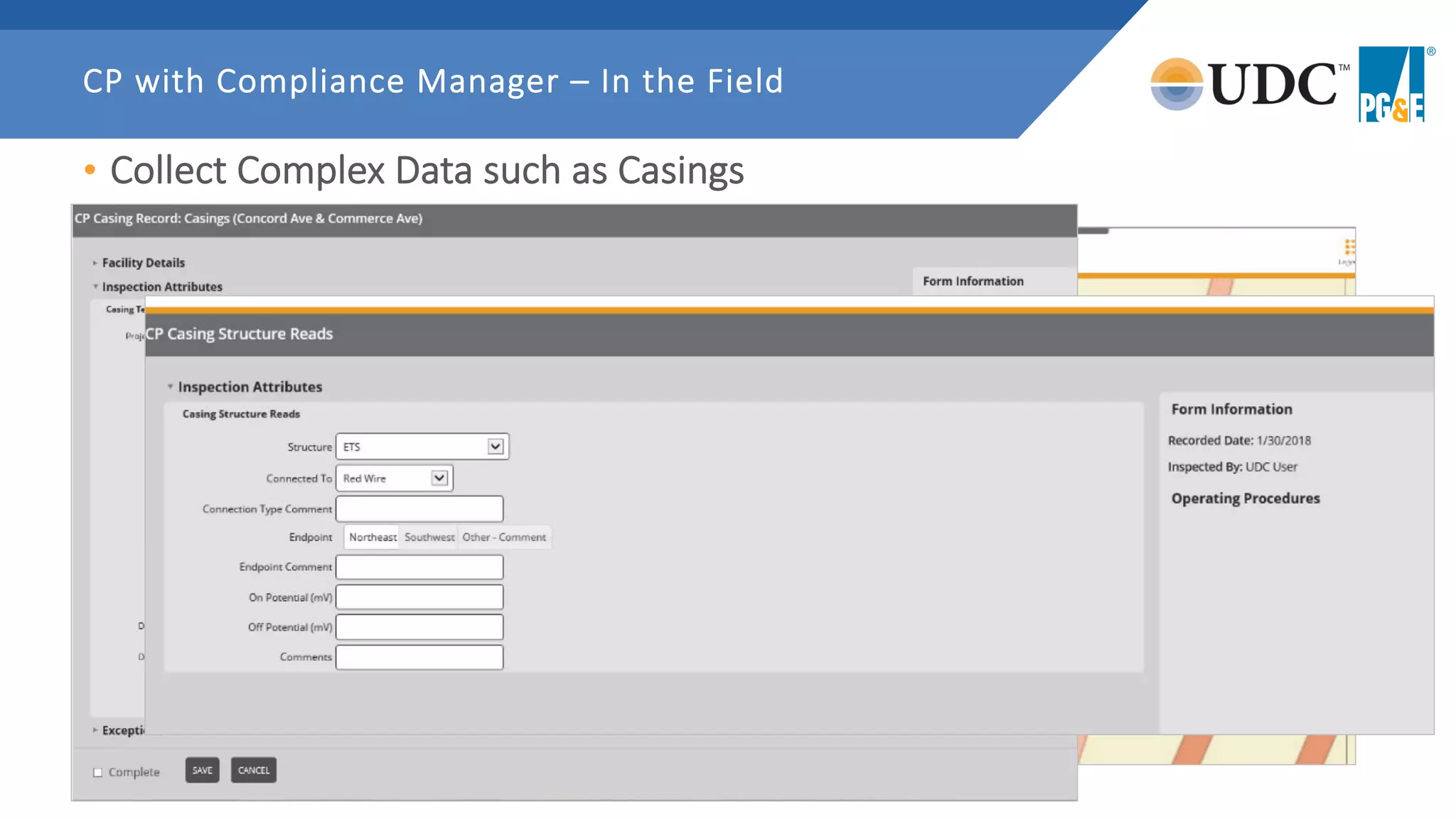

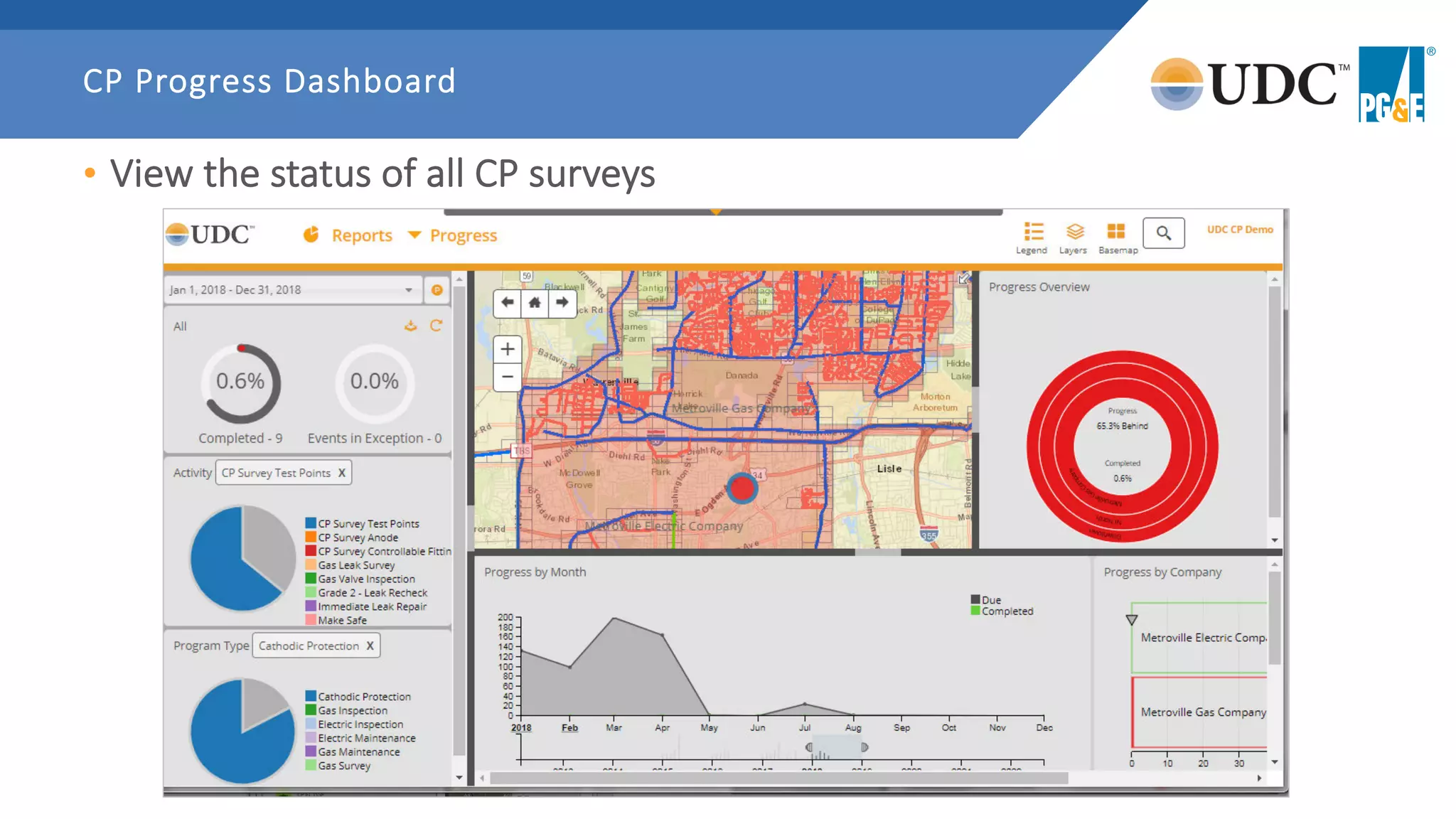

The document outlines PG&E's efforts to enhance its corrosion protection program following the San Bruno incident, focusing on evaluating over 3200 casings and 350,000 isolated steel locations as part of a five-year initiative. It highlights the implementation of a GIS-based system for efficient data management and compliance reporting within the corrosion program. Additionally, it describes the workflow involving field technicians, engineers, and construction teams to ensure proper cathodic protection across their extensive gas distribution network.