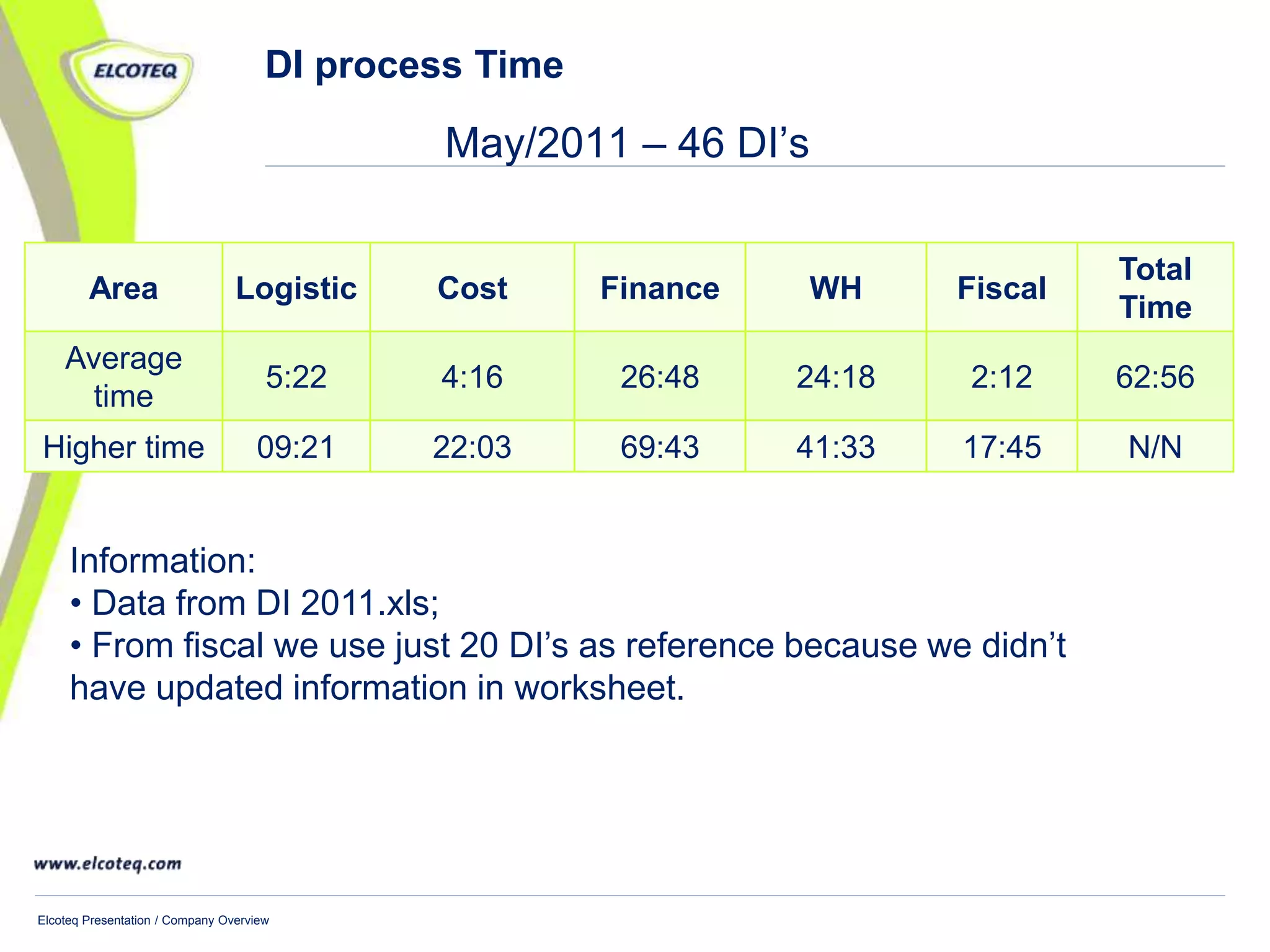

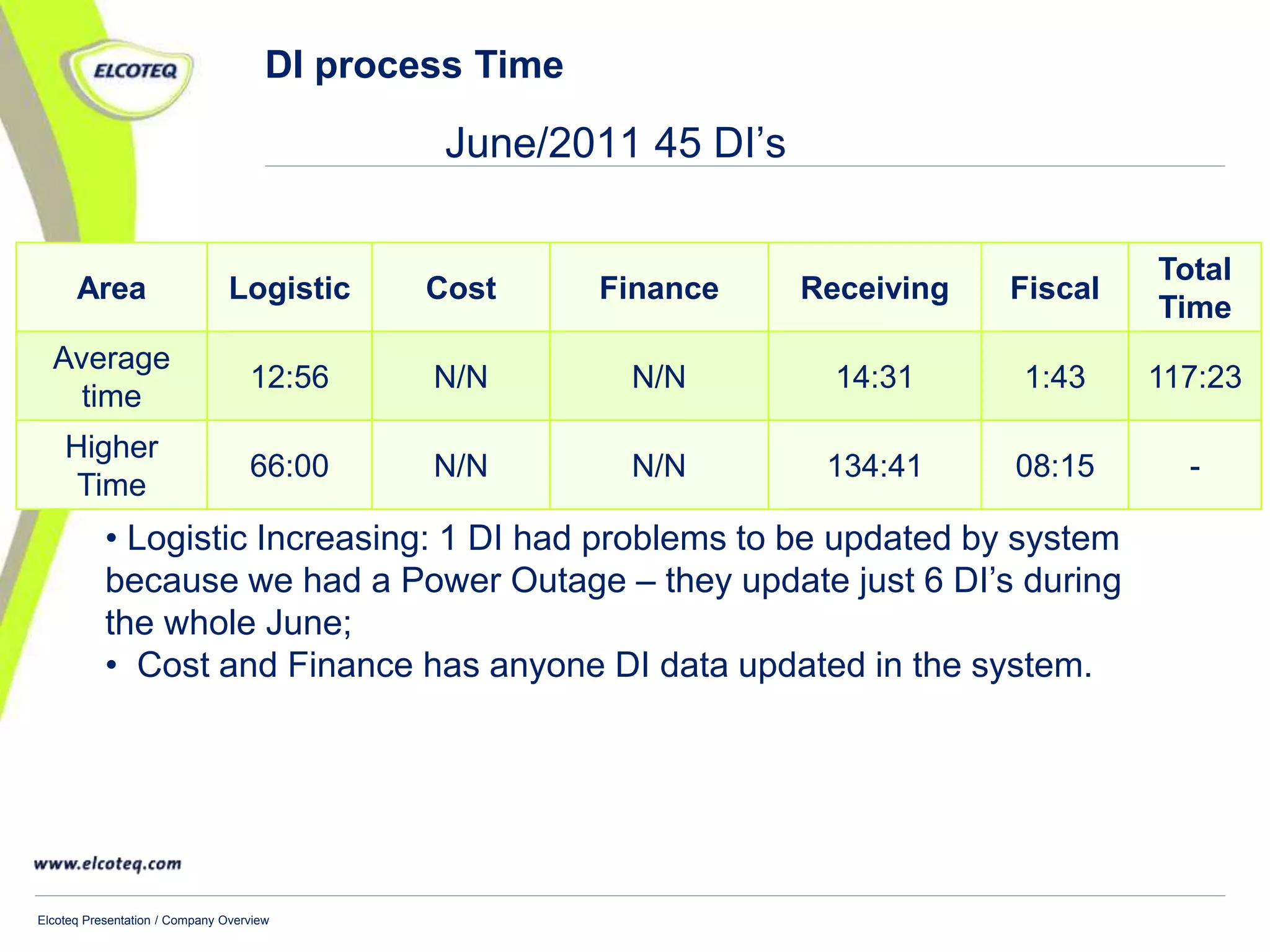

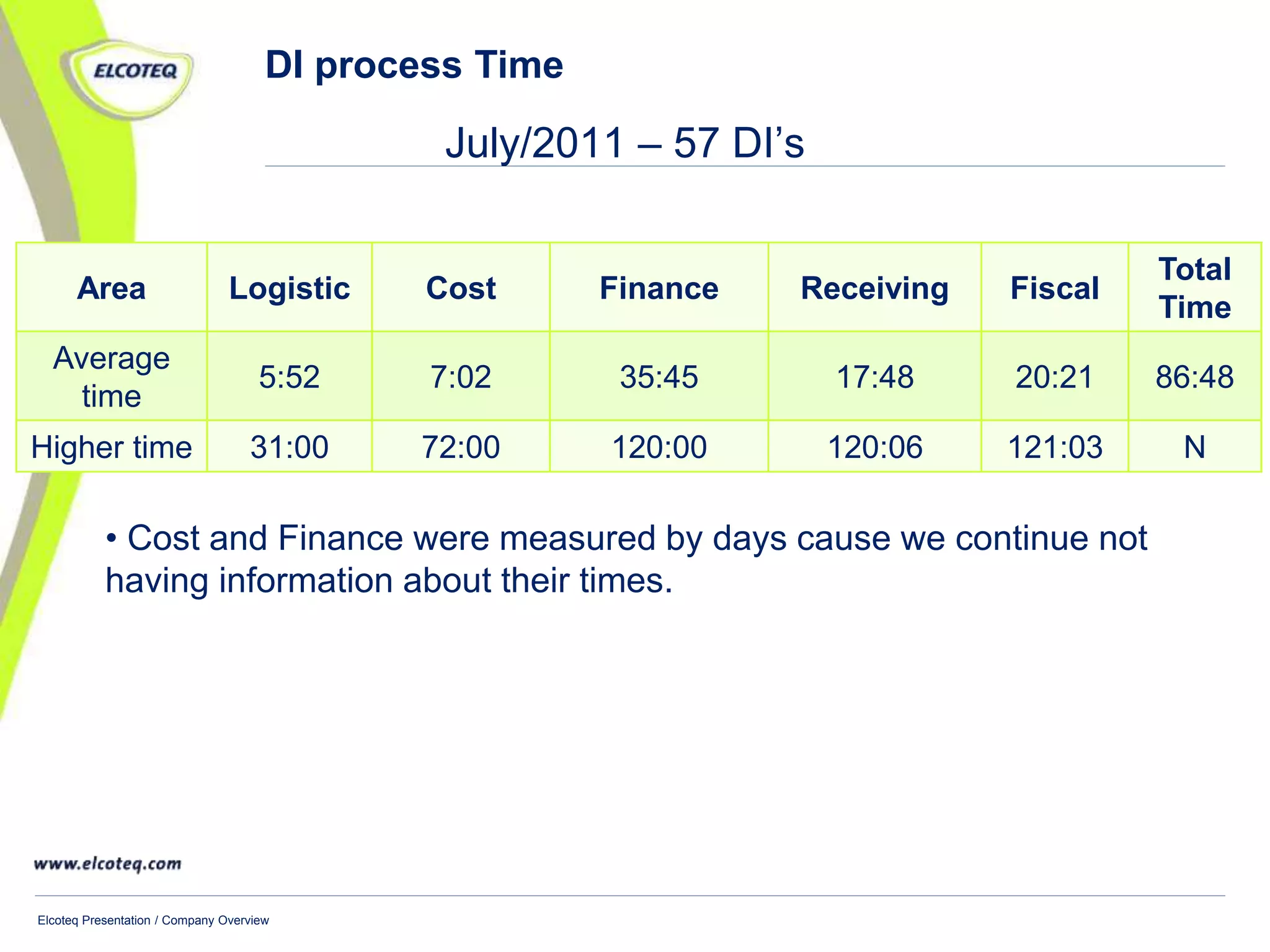

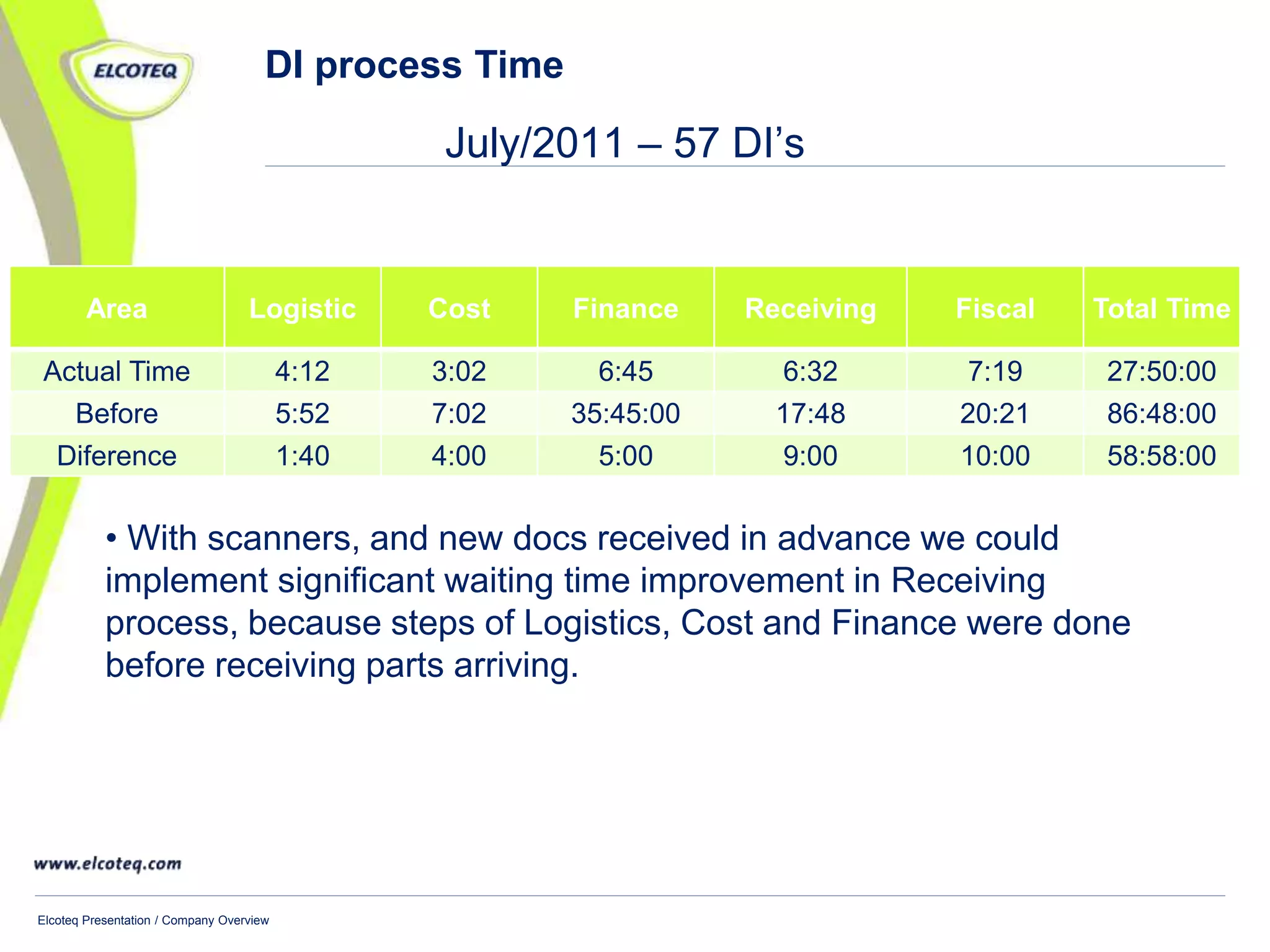

The document discusses the delivery inspection (DI) process times for Elcoteq Manaus from May 2011 to July 2011. It provides the average and higher times for each functional area to complete the DI process by month. In July 2011, two improvements were implemented - mobile stations for checking parts and creating labels, and generating spreadsheets in advance to create labels for incoming parts. This allowed logistic, cost, and finance teams to complete their entry tasks before parts arrived, significantly reducing the receiving time for the DI process compared to previous months.