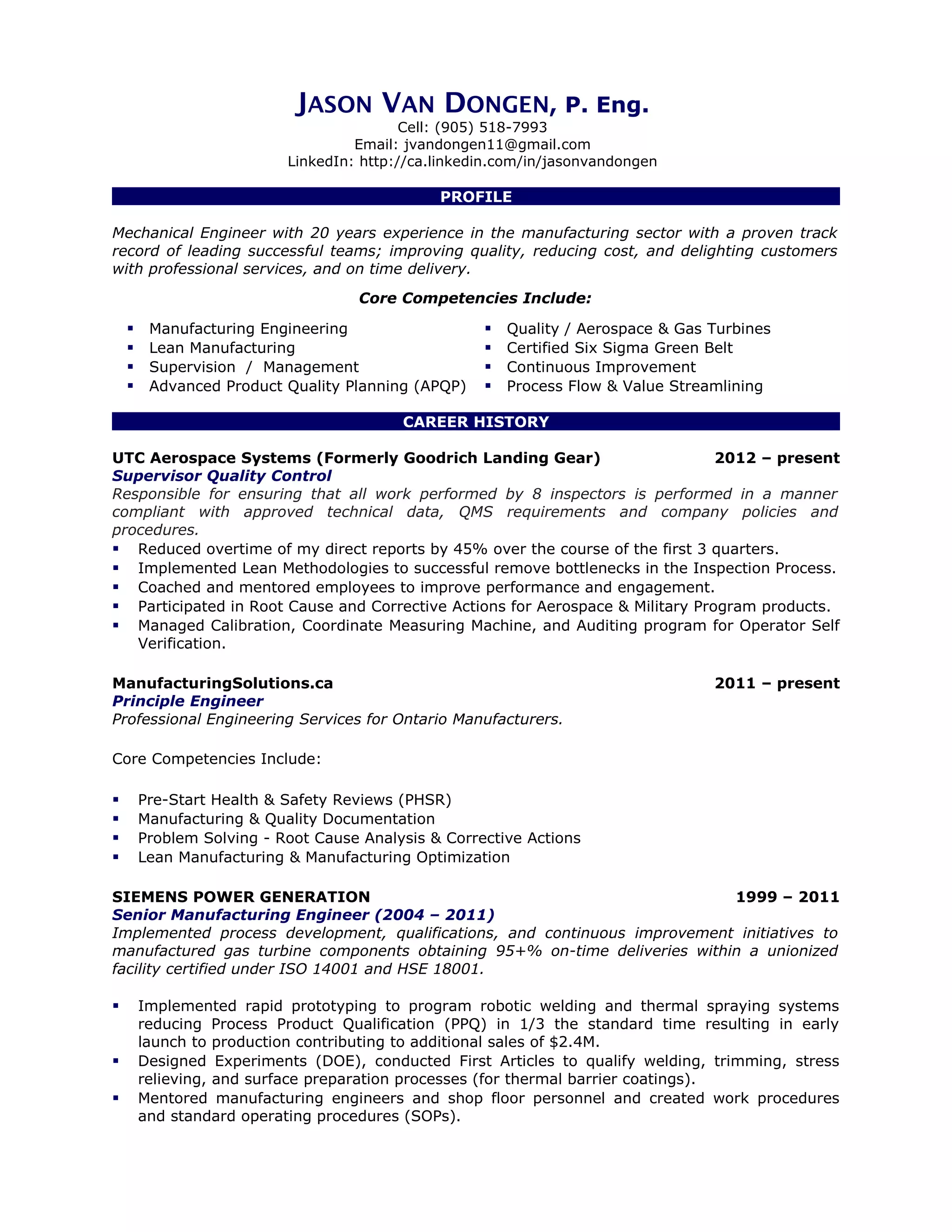

Jason Van Dongen is a mechanical engineer with 20 years of experience in manufacturing, specializing in quality control, lean manufacturing, and process optimization. He has held key positions at UTC Aerospace Systems and Siemens Power Generation, achieving significant improvements in quality and cost efficiency while mentoring teams. His educational background includes a Bachelor of Engineering from McMaster University and professional affiliations with the Ontario Society of Professional Engineers.