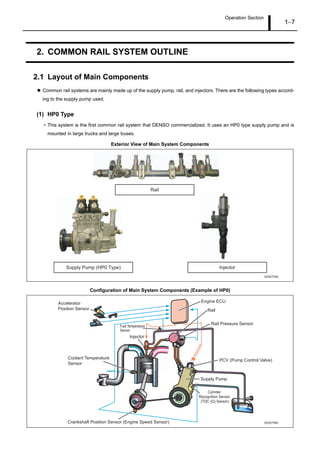

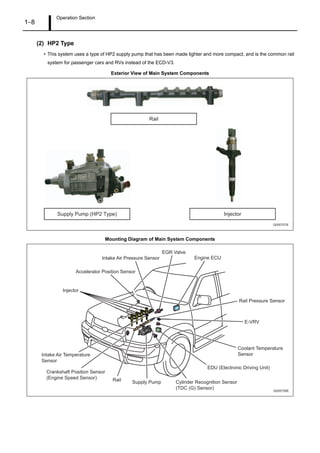

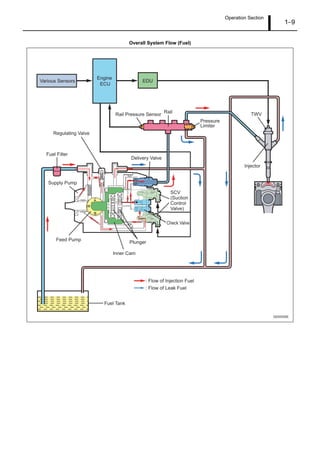

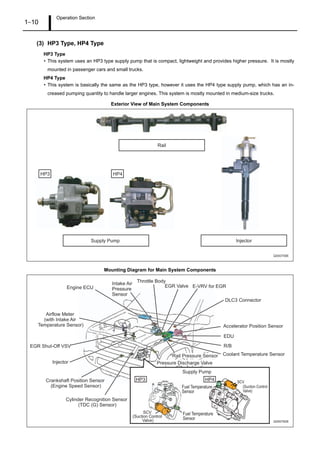

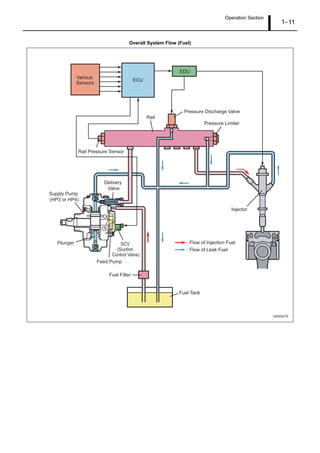

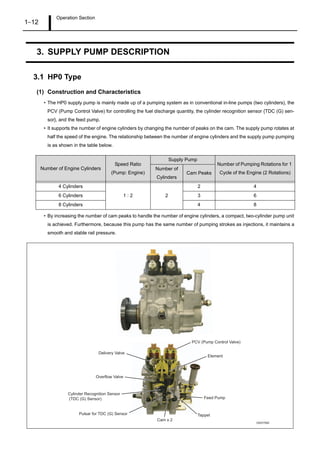

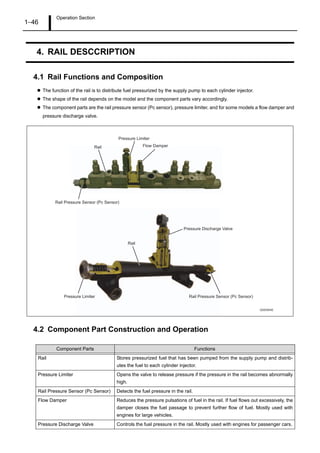

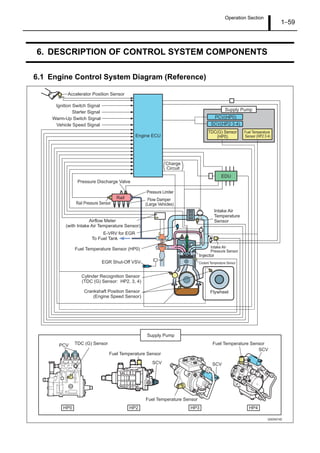

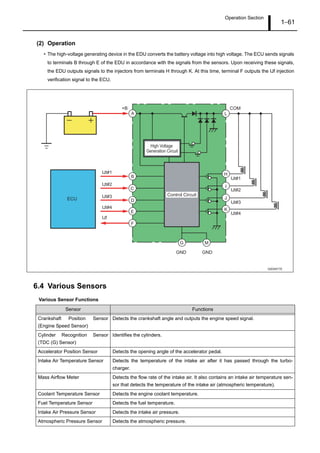

This document provides an overview of common rail diesel injection systems, including descriptions of key components and their operation. It discusses the supply pump, rail, injectors, control systems, diagnosis processes, and repair procedures. The supply pump pressurizes the fuel and supplies it to the high-pressure rail, which distributes it to the injectors. Electronic control modules precisely control fuel injection timing and quantity using inputs from sensors. Diagnostics involve checking codes, symptoms, and electrical circuits to isolate issues. Repair focuses on diagnosing specific systems or components causing malfunctions.

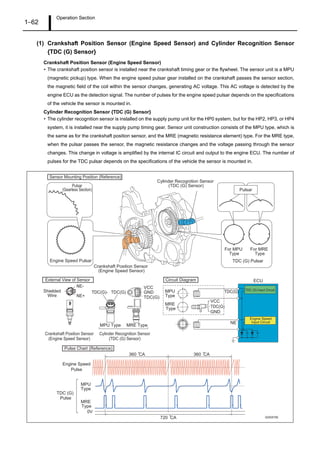

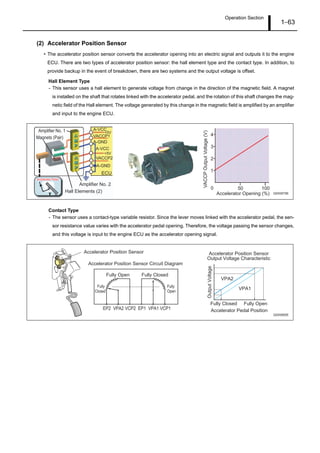

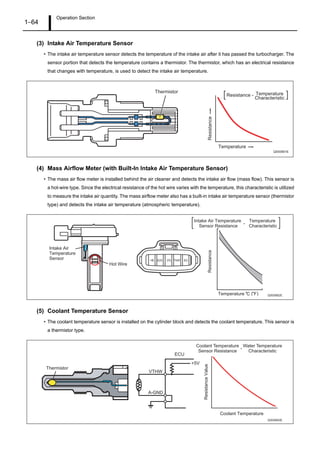

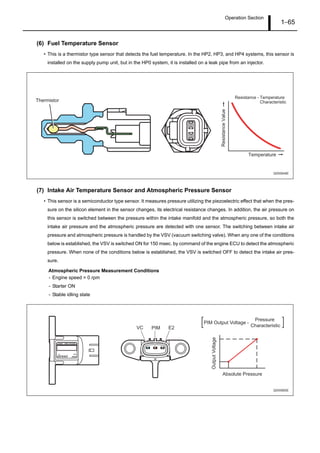

![Operation Section

1–71

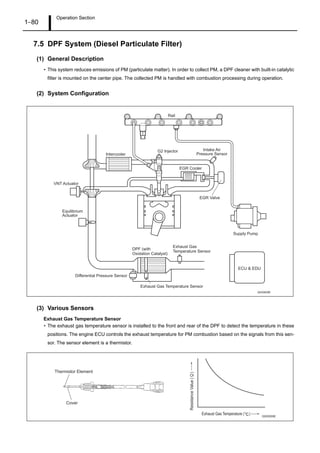

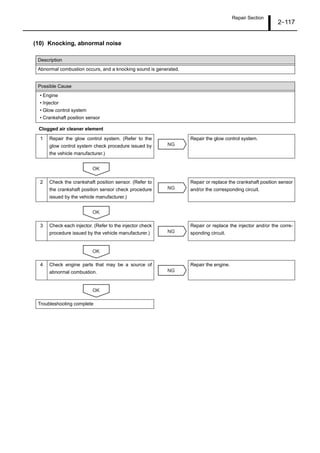

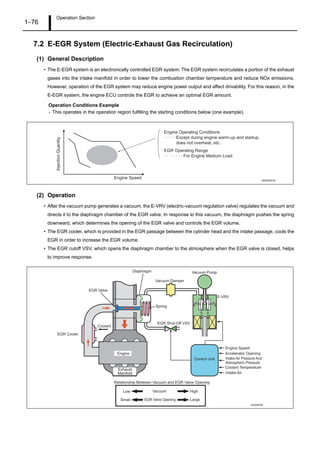

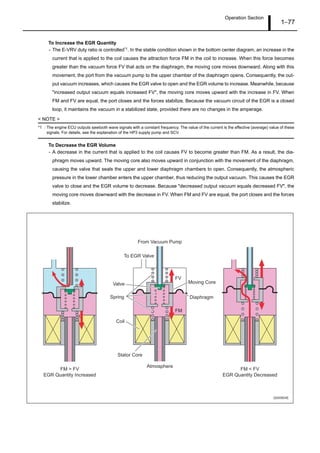

(4) Fuel Injection Rate Control

• Although the injection rate increases with the adoption of high-pressure fuel injection, the ignition lag, which is the

delay from the start of injection to the beginning of combustion, cannot be shortened to less than a certain period of

time. Therefore, the quantity of fuel injected until ignition takes place increases (the initial injection rate is too high),

resulting in explosive combustion simultaneous with ignition, and an increase in NOx and sound. To counteract this

situation, pilot injection is provided to keep the initial injection at the minimum requirement rate, to dampen the primary

explosive combustion, and to reduce NOx and noise.

Q000895E

Injection Rate

Heat Release Rate

Large First-Stage

Combustion

Small First-Stage

Combustion

Crankshaft Angle (deg) Crankshaft Angle (deg)

-20 TDC 20 40 -20 TDC 20 40

[Ordinary Injection] [Pilot Injection]](https://image.slidesharecdn.com/densohp-3servismanual-150326060210-conversion-gate01/85/Denso-hp-3-servis-manual-76-320.jpg)

![Operation Section

1–79

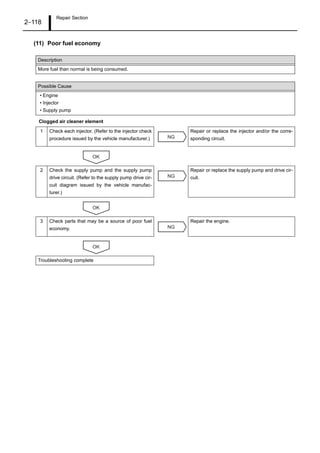

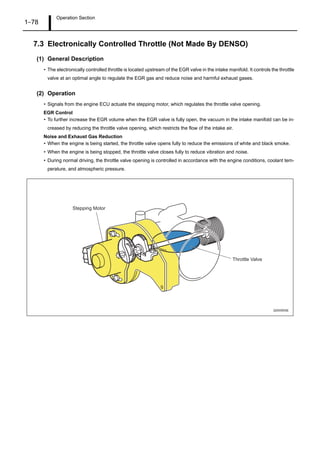

7.4 Exhaust Gas Control System

(1) General Description

• The exhaust gas control system is provided to improve warm-up and heater performance. This system actuates the

exhaust gas control valve VSV, which is attached to the exhaust manifold. It increases the exhaust pressure to in-

crease the exhaust temperature and engine load, in order to improve warm-up and heater performance.

(2) Operation

• The exhaust gas control system operates when the warm-up switch is ON, and all the conditions listed below have

been met.

Operation Conditions

- The EGR is operating.

- The coolant temperature is below 70°C.

- The ambient temperature is below 5°C.

- A minimum of 10 seconds have elapsed after starting the engine.

- The engine speed and fuel injection quantity are in the state shown in the graph below.

Air Cleaner

Exhaust Gas

Control Valve

Exhaust Gas

Control Valve

Vacuum Pump

VSV

Turbo Pressure

Sensor

Coolant Temperature

Sensor

EGR Valve Position

Sensor

Warm-Up Switch

Mass Airflow Meter

Cylinder

Recognition Sensor

(TDC (G) Sensor)

Accelerator

Position Sensor

Atmospheric

Pressure Sensor

ECU

Q000906E

Q000907E

WARM UP

Engine Speed

Operating Range

Extremely Low Torque

or Engine Speed Range

[Exhaust Gas Control System Operating Range]

InjectionQuantity](https://image.slidesharecdn.com/densohp-3servismanual-150326060210-conversion-gate01/85/Denso-hp-3-servis-manual-84-320.jpg)