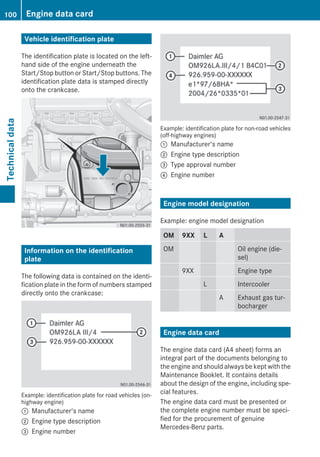

This document provides operating instructions for Mercedes-Benz OM 904-926 LA BlueTec® diesel engines. It contains information on engine components, safety symbols, operating the engine safely and correctly, maintenance procedures, and technical specifications. The instructions emphasize using genuine Mercedes-Benz parts and servicing the engine at authorized workshops. BlueTec® engines require AdBlue® to meet emissions regulations, and operation without it can affect the engine warranty and vehicle approval.