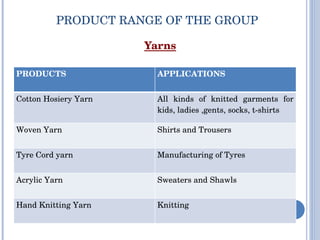

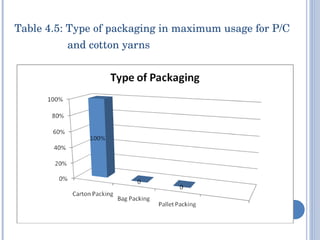

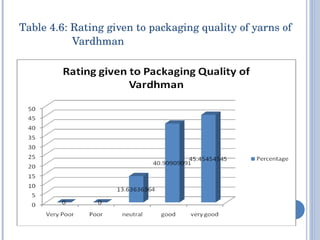

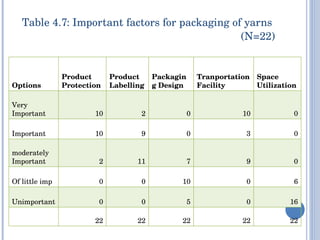

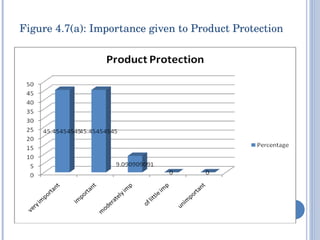

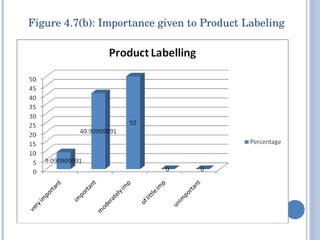

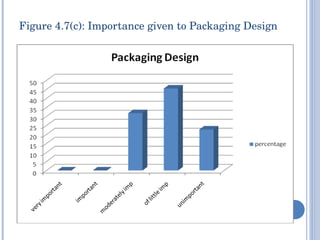

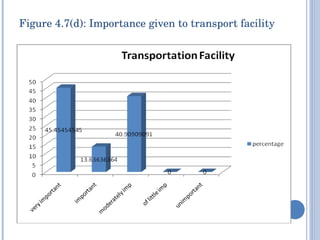

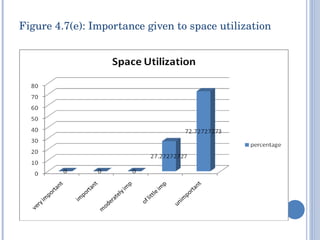

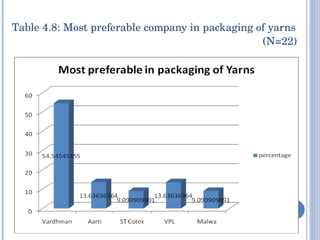

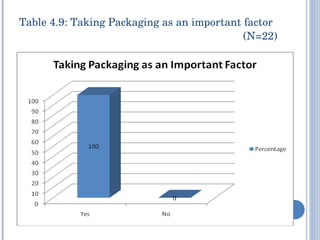

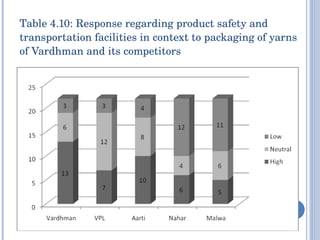

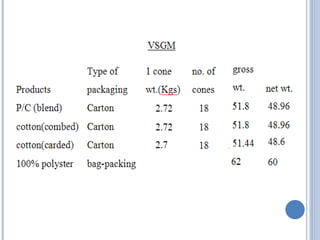

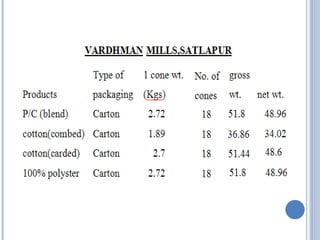

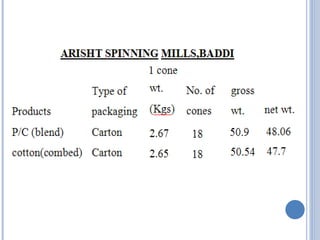

Vardhman Textiles produces yarns that are packaged for domestic, export, and in-house use. The researcher conducted a study to assess Vardhman's yarn packaging and identify ways to standardize packaging across product lines. Dealers indicated that product protection, labeling, and transport facilities were most important. The researcher suggests standardizing packaging specifications and using returnable packaging systems to reduce costs and environmental impact.