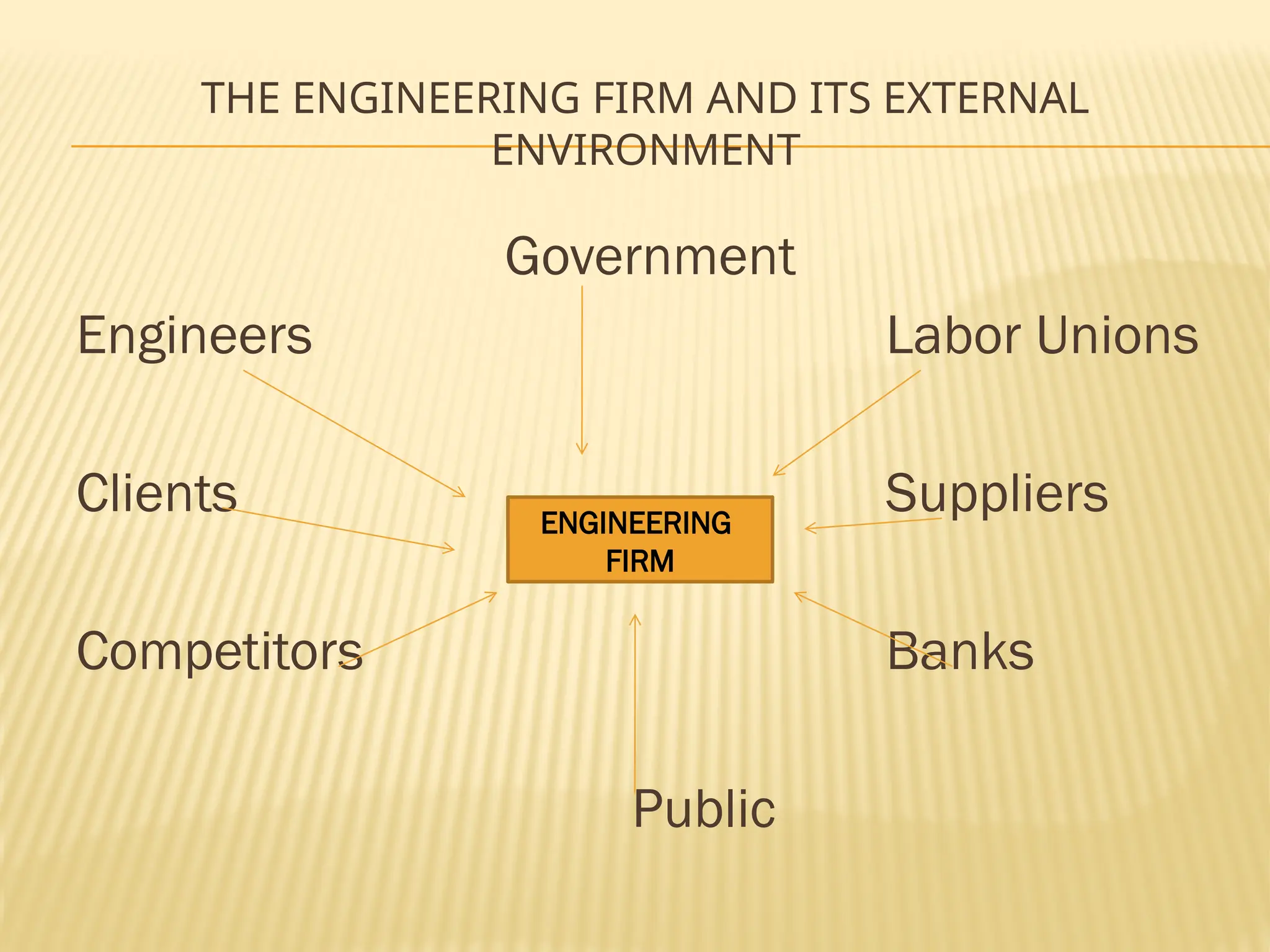

The document outlines the decision-making process in management, emphasizing the steps from diagnosing problems to evaluating and adapting decision results. It distinguishes between internal and external environmental factors influencing decisions and discusses qualitative and quantitative approaches for evaluating alternatives. Various quantitative models such as inventory management, queuing theory, and regression analysis are also described as tools for effective decision-making.