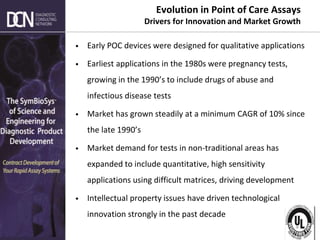

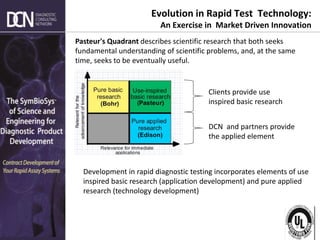

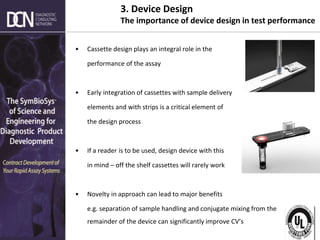

This document provides an overview of rapid diagnostic testing technologies and market opportunities. It discusses:

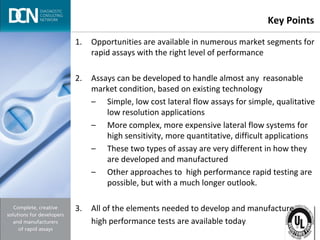

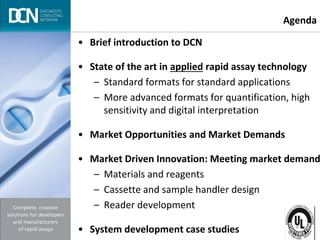

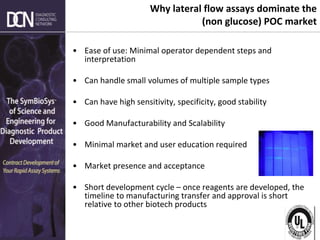

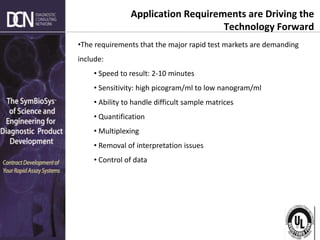

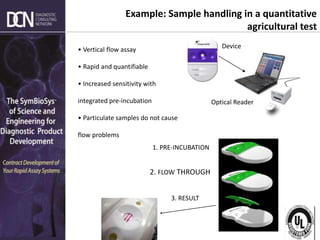

1) The state of rapid assay technologies, including standard lateral flow and more advanced formats for quantification and sensitivity.

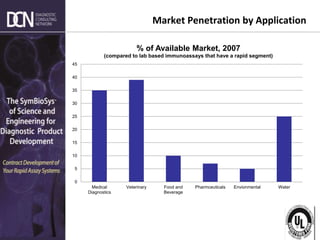

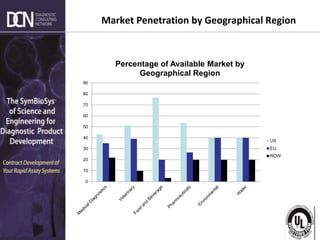

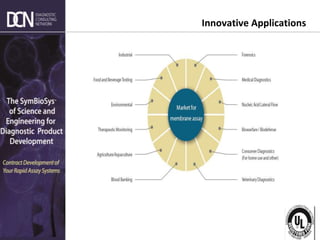

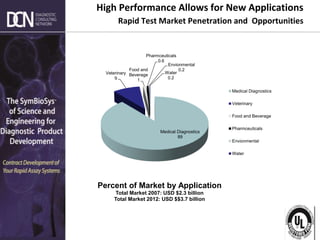

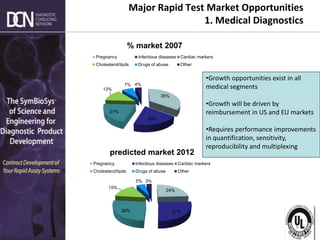

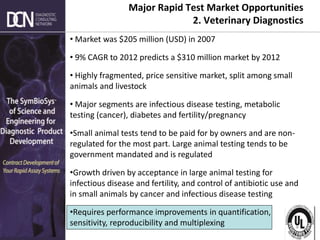

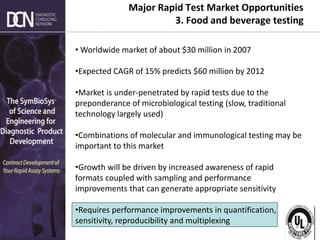

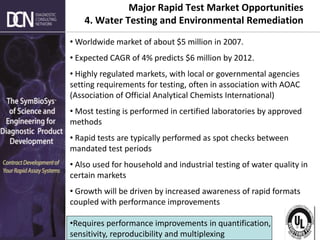

2) The major market segments and growth opportunities for rapid testing in medical diagnostics, veterinary, food/beverage, and environmental applications.

3) How market demands are driving technological innovation to improve assay performance characteristics like sensitivity and multiplexing.

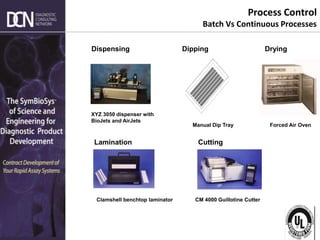

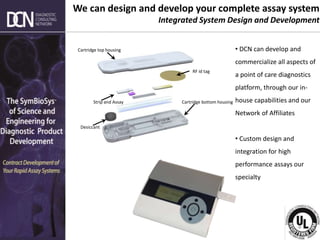

![Complete, creative solutions for developers and manufacturers of rapid assays

• Sensitive

• Affordable

• Simple to operate

• Small, Mobile and Robust

• Documented Results

• Objective Results

• Quantitative Results

ESE Quant

DCN’s Reader Partners: Handheld and Benchtop Readers

DCN distributes both ESE and LRE readers

DCN acts as the assay integration partner for both suppliers for

customers worldwide

LRE POC Reader

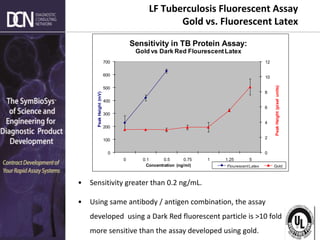

0

200

400

600

800

1000

1200

1400

0 200 400 600 800 1000 1200 1400

Data points

Intensity

[mV]

Scan1

Scan2

Scan3

Scan4

Scan5

Scan6

Scan7

Scan8

Scan9

Scan10

Scan11

Scan12

Scan13

Scan14

Scan15

Scan16

Scan17

Scan18

Scan19

Scan20

Control

Test](https://image.slidesharecdn.com/dcninovatecpresentationfinal-101110124949-phpapp01/85/Dcn-inovatec-presentation-final-31-320.jpg)

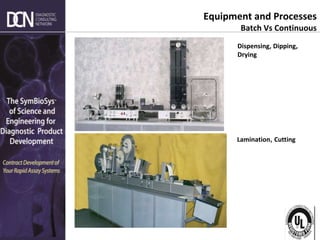

![Complete, creative solutions for developers and manufacturers of rapid assays

Alpha Amylase Detection in Wheat

0

50

100

150

200

250

300

350

400

srw170 srw138 srw139 cbh2.7 cbh2.8

Falling

Number

Wheat Sample

Comparisonof Values from Device andTrue Falling

NumberValues

True FN

DiagnostIQ AvgFN

DiagnostIQ Avg

[Amylase]

Hagberg Falling Numbers are determined by dropping a ball through a tube of

ground wheat. The time it takes in seconds for it to reach the bottom correlates

inversely to the amount of alpha-amylase in the wheat. High falling numbers

indicate low concentrations of alpha-amylase, and low falling numbers indicate a

high concentration of alpha-amylase.

Falling Number

True

FN

avg

amyl

conc.

St

Dev %CV

304 1.54 6.4 1.77%

244 21.82 3.56 1.27%

223 36.02

16.8

4 6.77%

142 144.05 6.57 4.77%](https://image.slidesharecdn.com/dcninovatecpresentationfinal-101110124949-phpapp01/85/Dcn-inovatec-presentation-final-42-320.jpg)