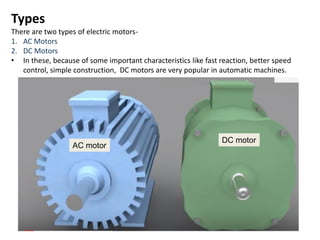

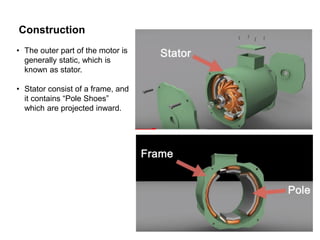

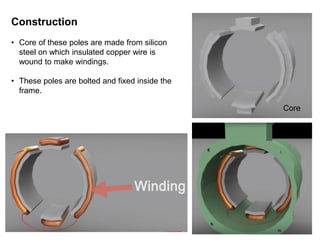

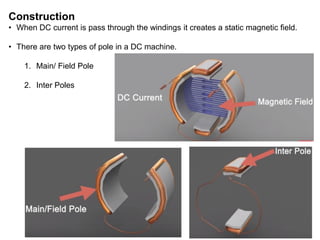

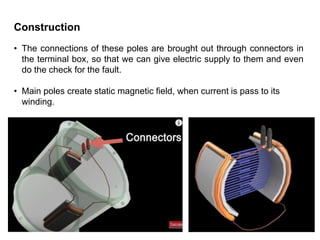

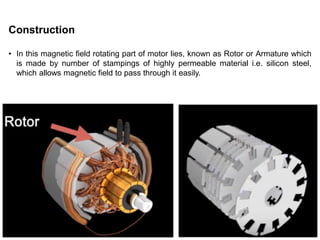

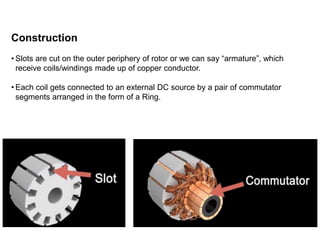

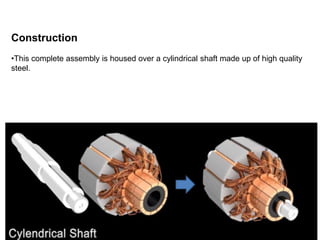

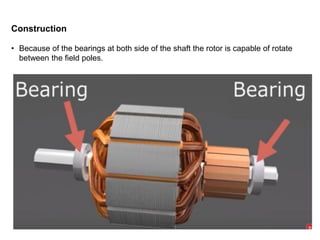

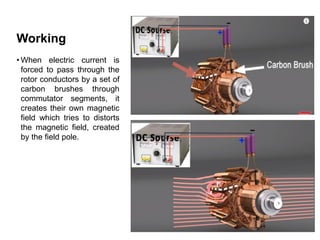

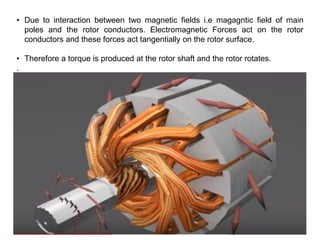

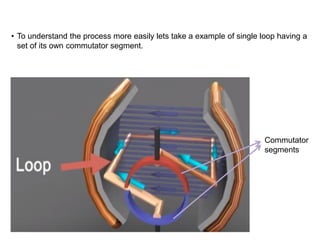

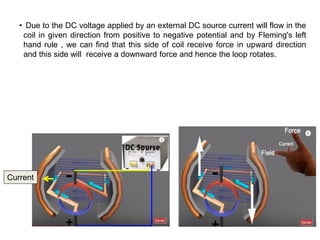

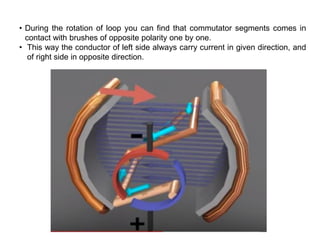

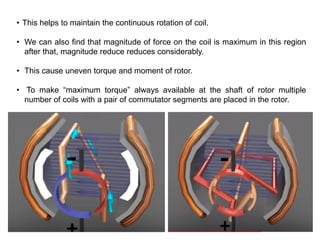

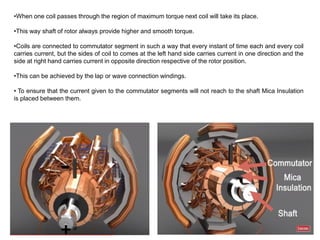

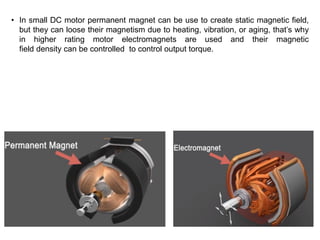

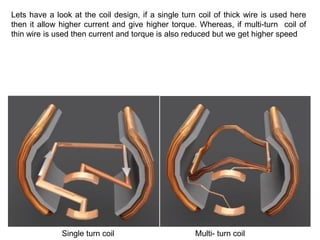

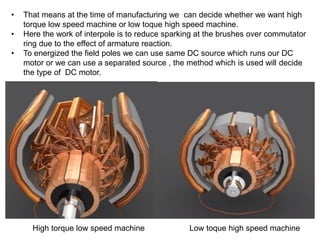

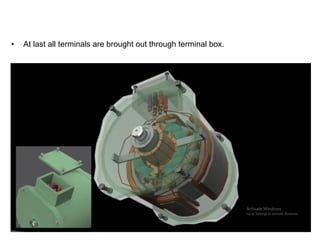

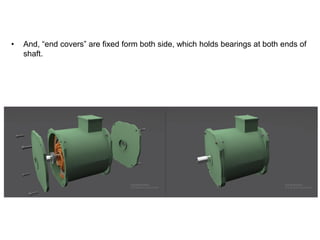

The document provides a detailed overview of the construction and working of DC motors, highlighting their importance in various applications due to features like fast reaction and speed control. It explains components such as the stator, rotor, and commutator segments, and their roles in generating torque through electromagnetic interaction. Additionally, it discusses design choices for achieving different torque and speed characteristics, along with the use of permanent magnets and electromagnets.