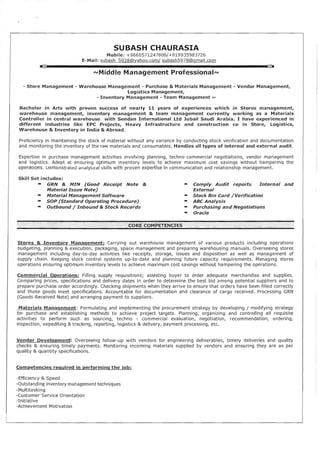

This document provides a summary of Subash Chaurasia's work experience and qualifications. It includes 11 years of experience in store management, warehouse management, inventory management, and team management. Currently working as a Materials Controller in Saudi Arabia, responsibilities include maintaining stock levels, inventory management, purchase management, and vendor management. Previous roles include Store Keeper positions in India with responsibilities such as day-to-day store operations, inventory control, materials receiving and issuing, and monthly reporting. Educational background includes a Bachelor's degree in Arts from India.