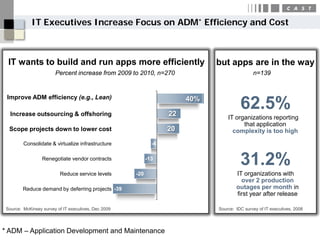

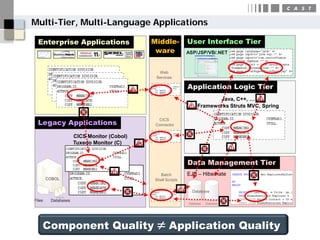

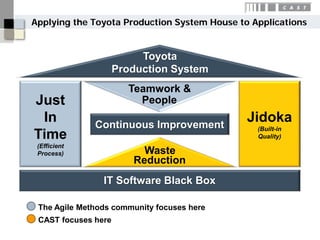

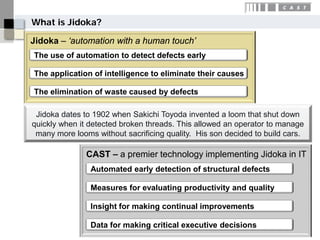

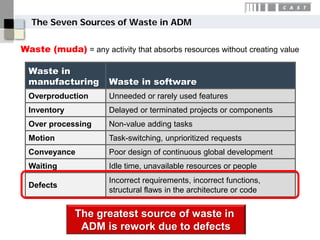

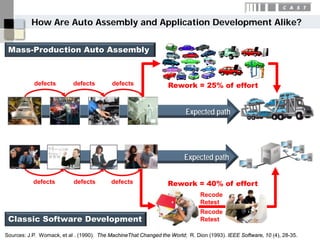

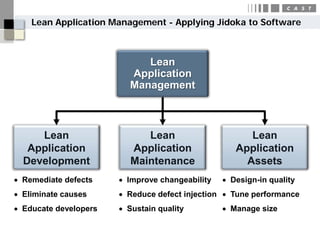

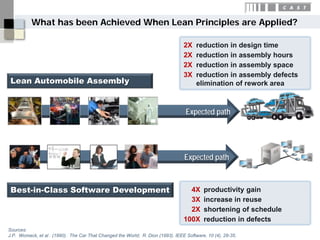

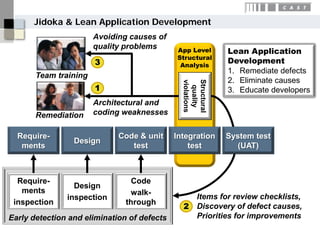

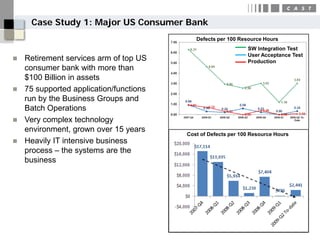

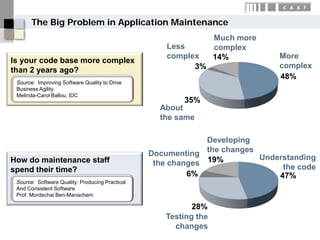

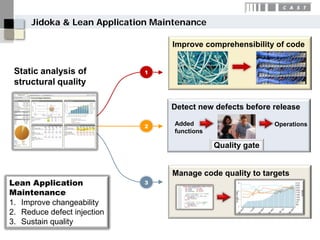

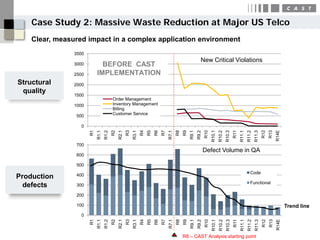

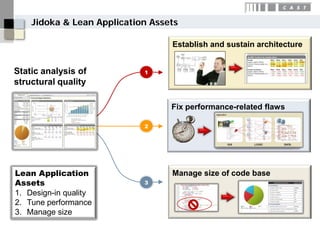

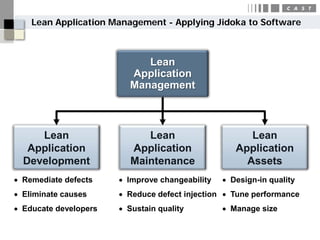

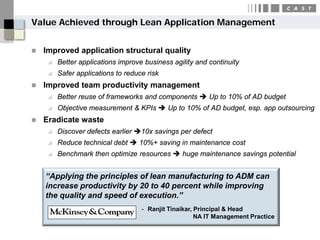

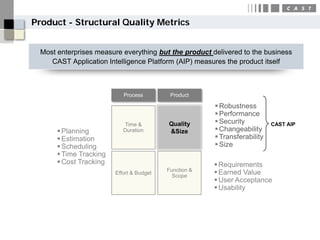

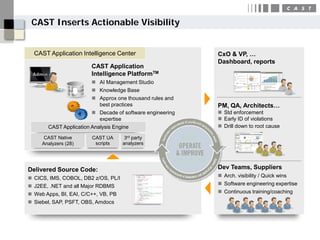

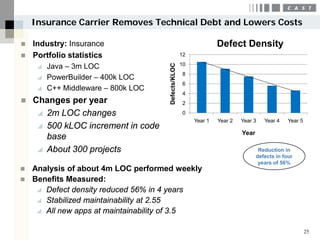

The document discusses the application of lean principles in software development, emphasizing efficiency and cost-cutting through strategies like outsourcing, process improvement, and waste reduction. It highlights the importance of early defect detection and structural quality metrics in enhancing productivity and mitigating risks in application development and maintenance. Case studies demonstrate significant improvements in quality and efficiency when these lean practices are implemented.