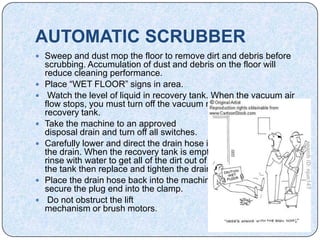

The document provides instructions and safety guidelines for operating and maintaining various pieces of custodial equipment, including vacuums, floor scrubbers, burnishers, and wet/dry vacs. It emphasizes the importance of proper care, inspection, and training to prevent equipment damage and injuries. Users should clean equipment after each use, check for wear and hazards, and only operate machines they have been trained on.