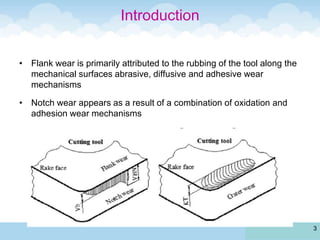

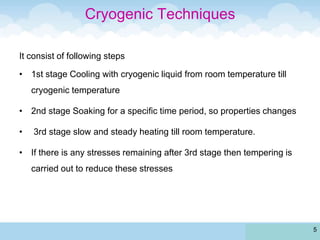

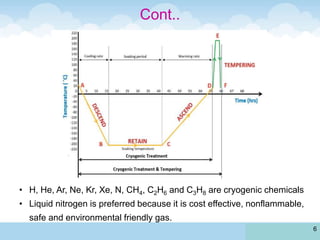

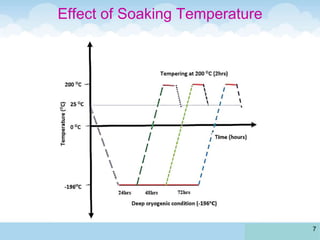

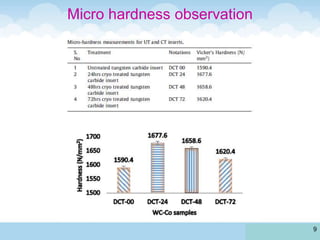

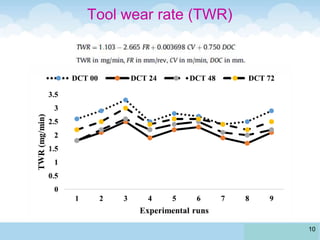

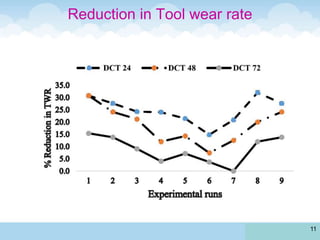

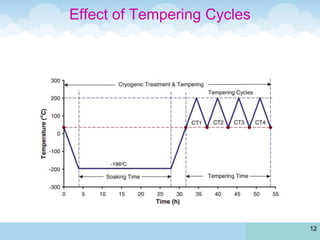

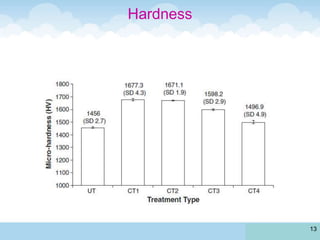

The document discusses the enhancement of tungsten carbide tools through a cryogenic processing method that improves their hardness and reduces wear rates. It outlines the characteristics of tungsten, the challenges faced during machining, and details the cryogenic treatment stages involving cooling, soaking, and heating. The findings indicate that a 24-hour soaking time results in optimal hardness and reduced tool wear, though tempering cycles have a marginal impact on performance.