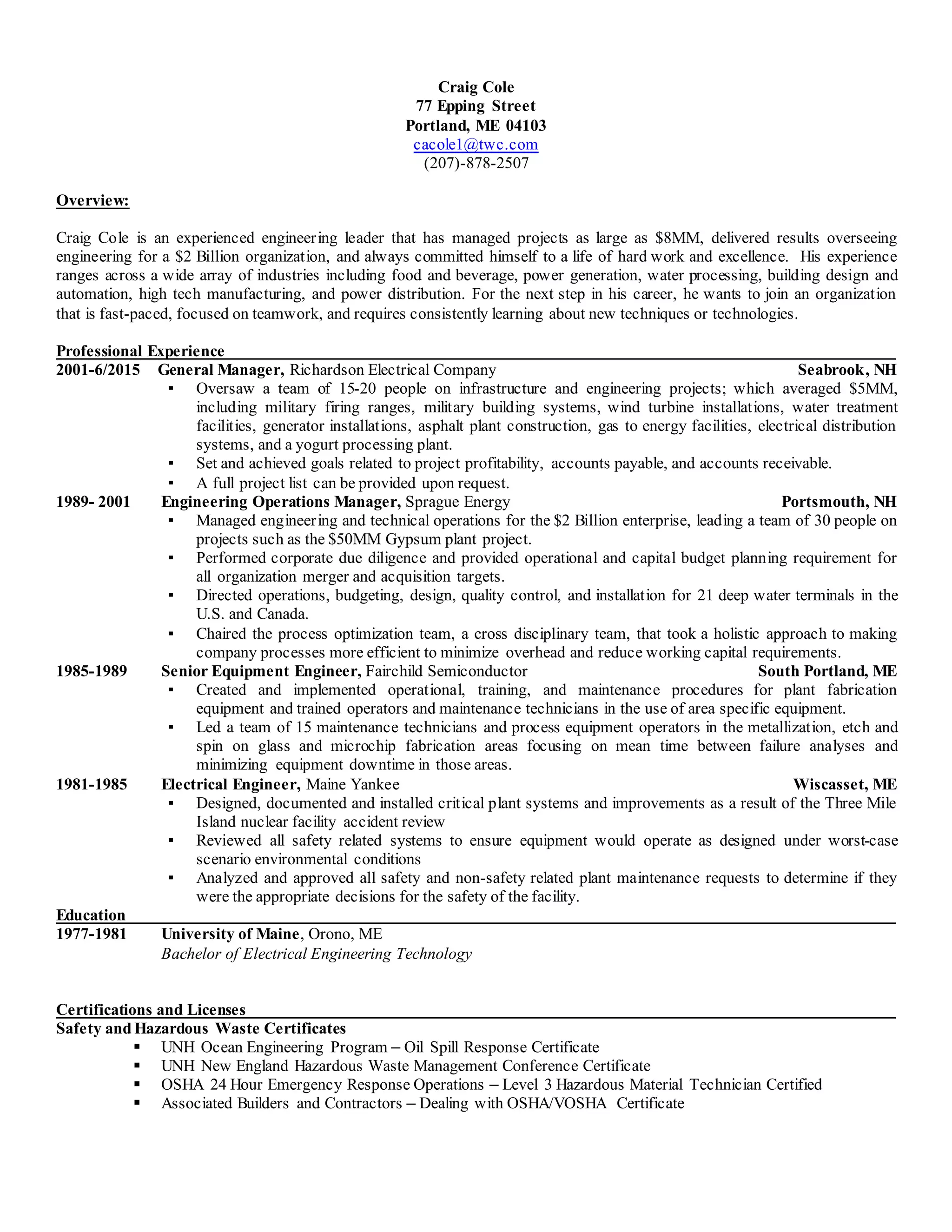

Craig Cole is an experienced engineering leader seeking a fast-paced position requiring continuous learning. He has overseen projects up to $8M and managed engineering for a $2B organization. Cole has experience across industries including manufacturing, power generation, and construction. He currently holds numerous safety, hazardous materials, and energy certificates.