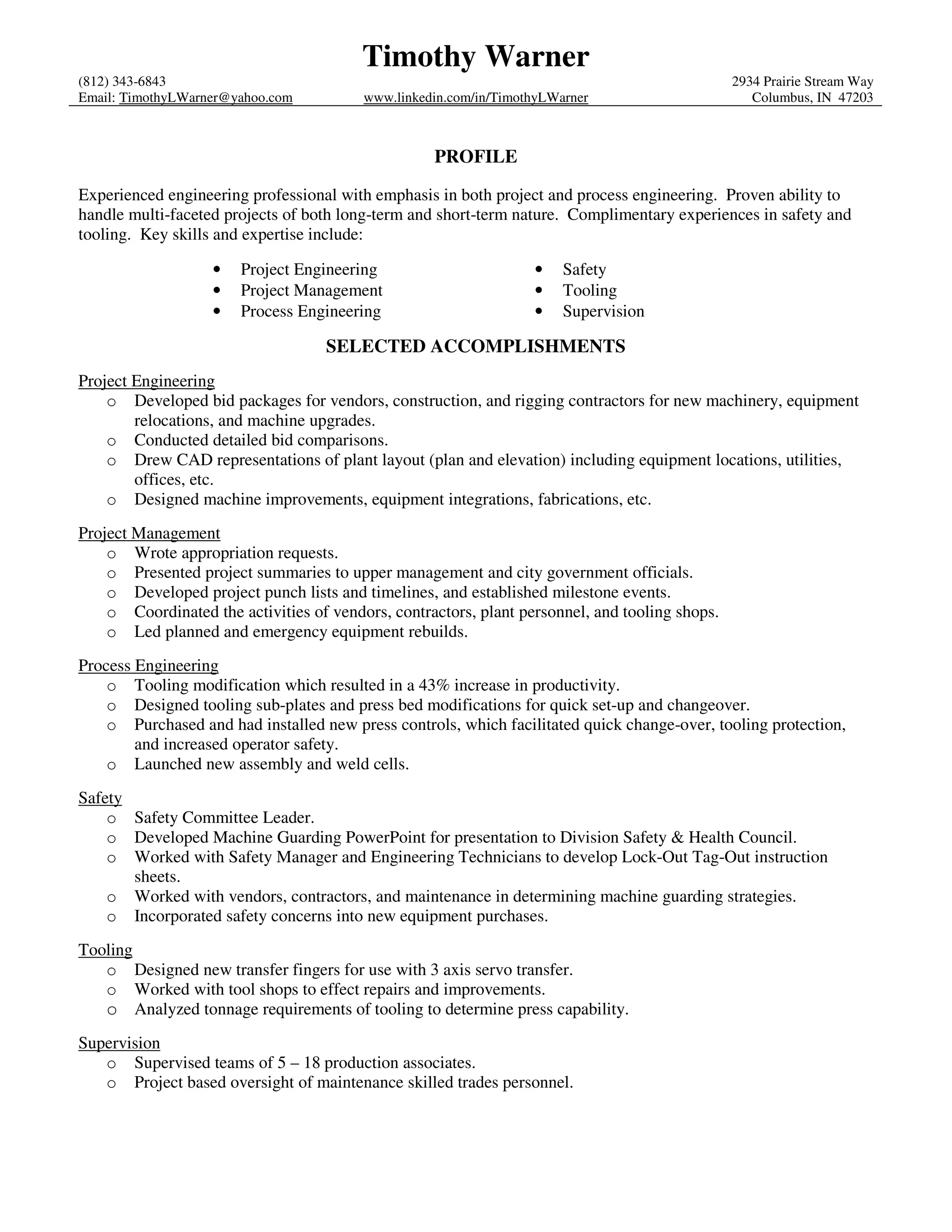

Timothy Warner is an experienced engineering professional with over 18 years of experience in project engineering, project management, process engineering, safety, and tooling. He has a proven track record of handling multi-faceted projects from long-term capital investments to emergency rebuilds. Some of his accomplishments include designing tooling modifications to increase productivity by 43%, leading the installation of an 1100 ton automatic transfer press line, and coordinating several press line relocations. He holds a B.S. in Mechanical Technology from Indiana State University.