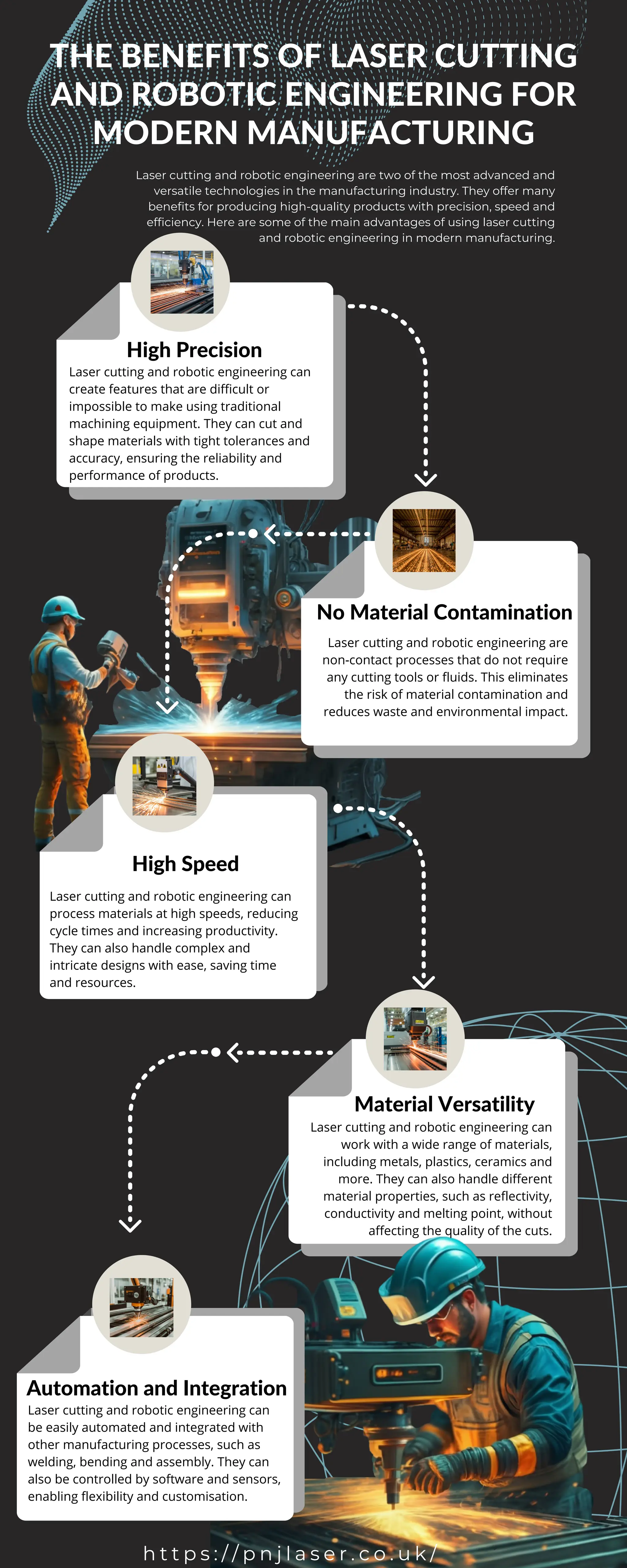

Laser cutting and robotic engineering are non-contact processes that eliminate material contamination and reduce waste, making them advantageous for modern manufacturing. These technologies offer high precision, speed, and material versatility, allowing for the creation of complex designs with tight tolerances. Additionally, they can be automated and integrated with other manufacturing processes, enhancing overall efficiency.