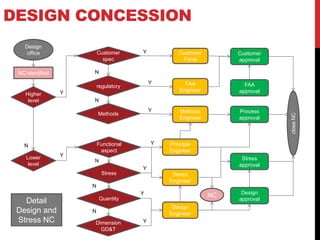

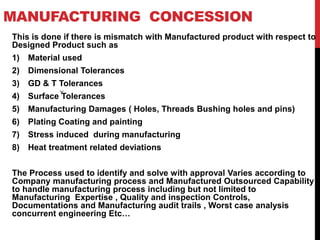

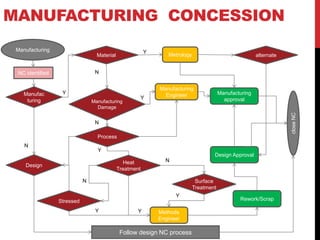

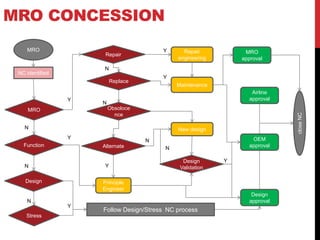

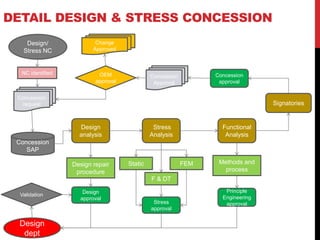

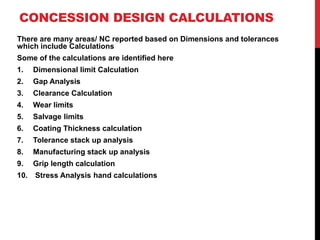

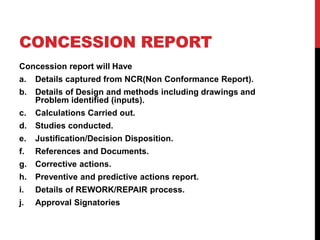

The document outlines the non-conformance management process, emphasizing different types of concessions including design, manufacturing, assembly, storage, and maintenance repair and overhaul (MRO). It details the identification and resolution of non-conformances at each stage, along with the criteria and methods for handling acceptability and corrective actions. The document also references relevant aerospace quality management standards and highlights the importance of comprehensive documentation and approval processes.