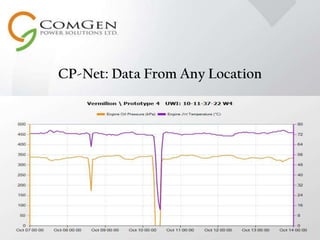

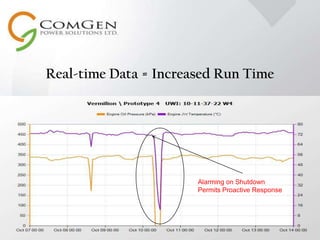

The document describes a low-cost remote monitoring solution that gathers operating data from field equipment like compressors and generators. It transmits the data via satellite network to a website where owners can access real-time readings and alarms from any location. This allows for more efficient equipment use through proactive issue response and optimization based on historical performance data.