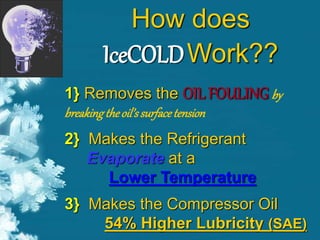

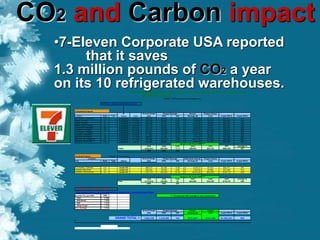

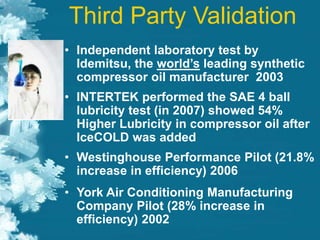

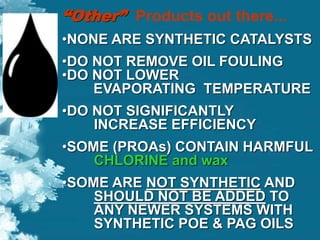

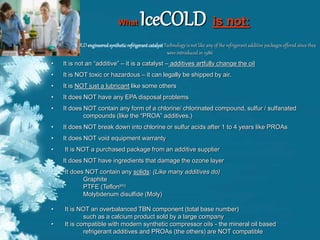

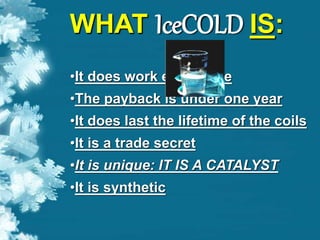

IceCOLD is a synthetic refrigerant catalyst that consistently saves customers up to 20% on air conditioning and refrigeration electric costs through 20% less maintenance and 20% longer equipment life. It is added to AC/refrigeration systems like Freon and works by removing oil fouling, making the refrigerant evaporate at a lower temperature, and increasing compressor oil lubricity by 54%. This results in 15-30% increased system capacity and cooling. Major customers report significant cost savings, lower CO2 emissions, and payback periods under one year. Independent laboratories and major companies have validated IceCOLD's performance improvements.