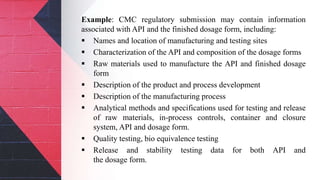

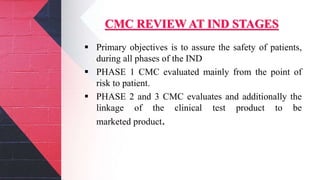

The document discusses Chemistry, Manufacturing, and Controls (CMC) in pharmaceutical development, emphasizing its role in regulatory affairs and ensuring drug quality, safety, and efficacy. It outlines the responsibilities of regulatory agencies and details CMC submission requirements, including manufacturing processes and quality testing. The importance of CMC is highlighted in the context of maintaining compliance and readiness for regulatory inspections.