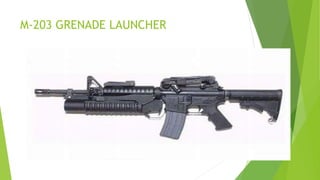

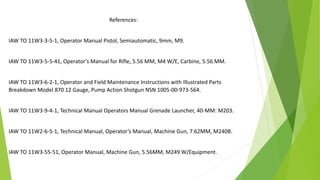

This document provides standardized procedures for USAF personnel to follow when handling small arms and light weapons, including loading, unloading, and clearing procedures. It outlines the specific steps to take for semi-automatic pistols, rifles, shotguns, grenade launchers, and machine guns. All personnel must use these procedures and handle weapons safely by keeping fingers off triggers and muzzles pointed in a safe direction during all handling.