This document appears to be a student's practicum report on studying the super structural construction process of a ten-story residential building. It includes sections on the company profile, project details and design specifications, construction materials and equipment used, and descriptions of the construction processes for columns, beams, slabs and stairs. The report is submitted to fulfill degree requirements and acknowledges assistance from supervisors and others involved in the project.

![66

5.9.1 Estimation of Column Casting

In my site there are six types of column such as- C1, C2, C3, C3A, C4 and C5. The estimation of

the materials that used on those columns is given below:

Column Type- C3A

Number of column = 2

Column height = 8.33'

Column size = (10"×40") = (0.83'×3.33')

Volume of column = (0.83'×3.33'×8.33') = 23.02 cft

Total volume = (23.02×2) = 46.04 cft [no. of column= 2]

Dry volume = (46.04×1.5) = 69.03 cft

Mixing ratio = 1:1.5:3

Summation of the ratio = (1+1.5+3) = 5.5

Cement = (69.03/5.5) ×1 = 12.55 cft

= 10.05 bags [1.25 cft = 1 bag]

Sand = (69.03/5.5) ×1.5 = 18.84 cft

Stone Chips = (69.03/5.5) ×3 = 37.67 cft

Estimation of the casting materials for column is given in table:

Column

Types

Column

Size

Column

Length

(ft)

No of

Column

Volume

(cft)

Dry

Volume

(cft)

Cement

(bag)

Sand

(cft)

Stone

Chips

(cft)

C1 (12″x20″) 8.33' 2 30.48 45.72 6.65 12.47 24.94

C2 (12″x20″) 8.33' 4 60.64 91.44 16.62 24.94 49.88

C3 (12″x30″) 8.33' 2 41.65 62.48 9.09 17.04 34.08

C3A (10″x40″) 8.33' 2 46.05 69.07 10.05 18.84 37.67

C4 (12″x30″) 8.33' 2 41.65 62.48 9.09 17.04 34.08

C5 (15″x30″) 8.33' 2 52.06 78.09 11.35 21.29 42.59

Total= 62.85 117.62 235.24

Table 5.7: Estimation of the Casting Materials of Column](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-83-320.jpg)

![67

But in the field total cement used = 60 bags [1 bag =1.25 cft]

= 75 cft

Dry volume = (75×5.5)/1 = 412.50 cft [mixing ratio =5.5]

Actual used of sand = (412.50/5.5) ×1.5 = 112.50 cft

Actual used of stone chips = (412.50/5.5) ×3 = 225 cft

Comparison of casting materials between estimation and actual used in the field is given below:

Materials Estimation Actual Used Difference (+/-)

Cement 62.85 bags 60 bags -2.85

Sand 117.62 cft 112.50 cft -5.12

Brick Chips 235.24 cft 225 cft -10.24

Table 5.8: Comparison of Casting Materials for Column

Figure 5.16: Comparison of Casting Materials for Column

Cement (bag) Sand (cft) Stone Chips (cft)

Estimated 62.85 117.62 235.24

Actual used 60 112.5 225

Difference 2.85 5.12 10.24

0

50

100

150

200

250

Comparison of Casting Materials](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-84-320.jpg)

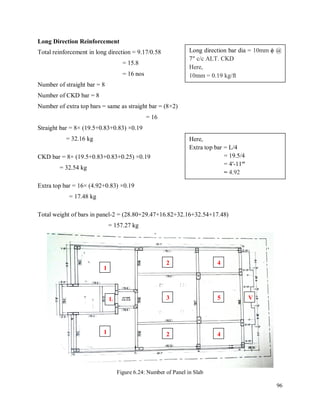

![102

6.10.1 Estimation of Beam & Slab Casting

In my site the beam and slab were casted together. But here, I estimated beam and slab casting

individually. There are 10 types of beam and 7 types of panel (including lobby and varandah) are

there. The estimation of the materials that used on beams and slab are given below:

Panel- 1

Number of panel = 2

Panel thickness = 5" = 0.43'

Panel size = (18.75ʹ×13.5ʹ)

Panel volume = (18.75ʹ×13.5ʹ×0.43) = 108.84 cft

Total casting = (108.84×2) = 217.68 cft [no. of panel= 2]

Dry volume = (217.68×1.5) = 326.53 cft

Mixing ratio = 1:2:4

Summation of the ratio = (1+2+4) = 7

Cement = (326.53/7) ×1 = 46.65 cft

= 37.32 bags [1.25 cft = 1 bag]

Sand = (326.53/7) ×2 = 93.29 cft

Brick Chips = (326.53/7) ×4 = 186.58 cft

Estimation of the casting materials for slab is given in table:

Panel

Name Panel Size

Panel

Thickness

(in)

Panel

No

Volume

(cft)

Dry

Volume

(cft)

Cement

(bag)

Sand

(cft)

Brick

Chips

(cft)

Panel-1 (18.75ʹ×13.5ʹ) 5″ 2 217.68 326.53 37.32 93.29 186.58

Panel-2 (19.5ʹ×9.17ʹ) 5″ 2 153.78 230.67 26.36 65.91 131.81

Panel-3 (19.5ʹ×18.58ʹ) 5.5″ 1 166.66 249.99 28.57 71.43 142.85

Panel-4 (14.25ʹ×9.17ʹ) 5″ 2 112.37 168.56 19.26 48.16 96.32

Panel-5 (18.58ʹ×14.25ʹ) 5″ 1 113.84 170.76 19.52 48.79 97.57

Lobby (10ʹ×4.33ʹ) 5″ 1 18.62 27.93 3.19 7.98 15.96

Varanda (2.83ʹ×37.33ʹ) 6″ 1 52.82 79.23 9.05 22.64 45.27

Total= 143.27 358.2 716.36

Table 6.15: Estimation of the Casting Materials of Slab](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-119-320.jpg)

![103

Beam Type- FB1

Number of beam = 2

Beam length = 55.58'

Beam size = (10"×21") = (0.58'×1.75')

Volume of column = (0.58'×1.75'×55.58') = 56.41 cft

Total casting = (56.41×2) = 112.82 cft [no. of beam= 2]

Dry volume = (112.82×1.5) = 169.23 cft

Mixing ratio = 1:2:4

Summation of the ratio = (1+2+4) = 7

Cement = (169.23/7) ×1 = 24.18 cft

= 19.34 bags [1.25 cft = 1 bag]

Sand = (169.23/7) ×2 = 48.35 cft

Brick Chips = (169.23/7) ×4 = 96.70 cft

Estimation of the casting materials for beam is given in table:

Beam

Types Beam Size

Beam

Length

(ft)

No of

Beam

Volume

(cft)

Dry

Volume

(cft)

Cement

(bag)

Sand

(cft)

Brick

Chips

(cft)

FB-1 (10″x21″) 55.58ʹ 2 112.82 169.23 19.34 48.35 96.70

FB-2 (10″x21″) 36.25ʹ 2 105.13 157.69 18.02 45.05 90.09

FB-3 (10″x21″) 18.33ʹ 2 53.16 79.74 9.11 22.78 45.56

FB-4 (10″x21″) 18.67ʹ 1 27.07 40.61 4.64 11.60 23.21

FB-5 (10″x21″) 15.17ʹ 2 43.99 65.98 7.54 18.85 37.70

FB-6A (10″x21″) 40.25ʹ 1 58.36 87.54 10 25.01 50.02

FB-7 (10″x24″) 40.25ʹ 1 66.82 100.22 11.45 28.63 57.27

FB-8 (10″x21″) 40.25ʹ 1 58.36 87.54 10 25.01 50.02

FB-9 (10″x21″) 7.17ʹ 2 20.79 31.19 3.56 8.91 17.82

FB-10 (10″x18″) 11.67ʹ 1 14.59 21.88 2.50 6.25 12.50

Total= 96.16 240.4 480.80

Table 6.16: Estimation of the Casting Materials of Beam](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-120-320.jpg)

![104

As I said earlier, the beam and slab was casted together in my site. So the summation of the

casting materials of beam and slab are:

The total cement estimation = (96.16+143.27) = 239.43 bags

The total sand estimation = (240.40+358.20) = 598.60 cft

The total brick chips estimation = (480.80+716.36) = 1197.16 cft

But in the field total cement used = 226 bags = 282.50 cft [1 bag =1.25 cft]

Dry volume = (282.50×7)/1 = 1977.50 cft [mixing ratio =7]

Actual used of sand = (1977.50/7) ×2 = 565 cft

Actual used of brick chips = (1977.50/7) ×4 = 1130 cft

Comparison between estimation and actual use of casting materials in the field is given below:

Materials Estimation Actual Used Difference (+/-)

Cement 239.43 bags 226 bags -13.43

Sand 598.60 cft 565 cft -33.60

Brick Chips 1197.16 cft 1130 cft -67.16

Table 6.17: Comparison of Casting Materials for Beam & Slab

Figure 6.32: Comparison of Casting Materials for Beam & Slab

Cement (bag) Sand (cft) Brick Chips (cft)

Estimated 239.43 598.6 1197.16

Actual used 226 565 1130

Difference 13.43 33.6 67.16

0

200

400

600

800

1000

1200

1400

Comparison of Casting Materials](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-121-320.jpg)

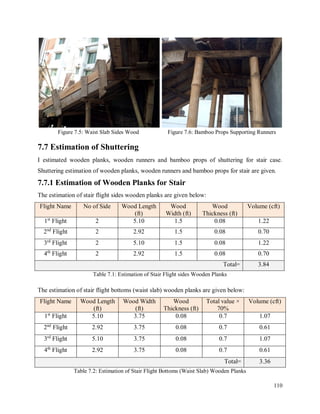

![116

7.10.1 Estimation of Stair Casting

The estimation of the materials that used on stair casting is given below:

Landing

Number of landing = 4

Landing thickness = 6" = 0.5'

Landing area = (3.75ʹ×3.75ʹ)

Landing volume = (3.75ʹ×3.75ʹ×0.5') = 7.03 cft

Total volume = (7.03×4) = 28.12 cft [no. of landing= 4]

Dry volume = (28.12×1.5) = 42.18 cft

Mixing ratio = 1:2:4

Summation of the ratio = (1+2+4) = 7

Cement = (42.18/7) ×1 = 6.03 cft

= 4.82 bags [1.25 cft = 1 bag]

Sand = (42.18/7) ×2 = 12.05 cft

Brick Chips = (42.18/7) ×4 = 24.10 cft

Waist Slab

Number of waist slab = 2

Waist slab thickness = 6" = 0.5'

Waist slab area = (3.75ʹ×5.10ʹ) [1st

and 3rd

waist slab]

Waist slab volume = (3.75ʹ×5.10ʹ×0.5') = 9.56 cft

Total volume = (9.56×2) = 19.13 cft [no. of waist slab= 2]

Dry volume = (19.13×1.5) = 28.69 cft

Mixing ratio = 1:2:4

Summation of the ratio = (1+2+4) = 7

Cement = (28.69/7) ×1 = 4.09 cft

= 3.28 bags [1.25 cft = 1 bag]

Sand = (28.69/7) ×2 = 8.19 cft

Brick Chips = (28.69/7) ×4 = 16.39 cft](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-133-320.jpg)

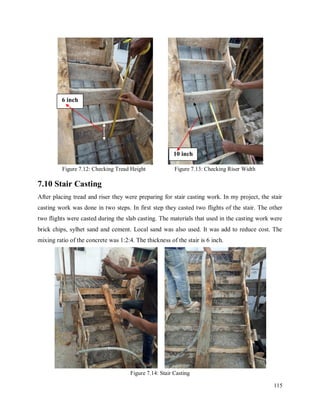

![117

Steps

Number of steps = 16

Step length = 3.75ʹ

Tread length = 6" = 0.5ʹ

Riser height = 10" = 0.83ʹ

Step area = (1/2×0.5ʹ×0.83ʹ)

Step volume = (1/2×0.5ʹ×0.83'×3.75ʹ) = 0.78 cft

Total volume = (0.78×16) = 12.45 cft [no. of step= 16]

Dry volume = (12.45×1.5) = 18.68 cft

Mixing ratio = 1:2:4

Summation of the ratio = (1+2+4) = 7

Cement = (18.68/7) ×1 = 2.67 cft

= 2.14 bags [1.25 cft = 1 bag]

Sand = (18.68/7) ×2 = 5.34 cft

Brick Chips = (18.68/7) ×4 = 10.68 cft

Estimation of the casting materials for stair is given in table:

Flight

Types

NOS Area (sft) Thickness

(in)

Volume

(cft)

Dry

Volume

(cft)

Cement

(bag)

Sand

(cft)

Brick

Chips

(cft)

Landing 4 3.75ʹ×3.75ʹ 6" 28.12 42.18 4.82 12.05 24.10

Waist Slab

(1st

& 3rd

)

2 3.75ʹ×5.10ʹ 6" 19.13 28.69 3.80 8.19 16.39

Waist Slab

(2nd

& 4th

)

2 3.75ʹ×2.92ʹ 6" 10.95 16.43 1.88 4.69 9.39

Steps 16 1/2×0.5ʹ×0.83ʹ - 12.45 18.68 2.14 5.34 10.68

Total= 12.64 30.27 60.56

Table 7.8: Estimation of the Casting Materials of Stair](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-134-320.jpg)

![118

But in the field total cement used = 11 bags [1 bag = 1.25 cft]

= 13.75 cft

Dry volume = (13.75×7)/1 = 96.25 cft [mixing ratio = 7]

Actual used of sand = (96.25/7) ×2 = 27.50 cft

Actual used of brick chips = (96.25/7) ×4 = 55 cft

Comparison of casting materials between estimation and actual used in the field is given below:

Materials Estimation Actual Used Difference (+/-)

Cement 12.64 bags 11 bags -1.64

Sand 30.27 cft 27.50 cft -2.77

Brick Chips 60.56 cft 55 cft -5.56

Table 7.9: Comparison of Casting Materials for Stair

Figure 7.15: Comparison of Casting Materials for Stair

Cement (bag) Sand (cft) Stone Chips (cft)

Estimated 12.64 30.27 60.56

Actual used 11 27.5 55

Difference 1.64 2.77 5.56

0

10

20

30

40

50

60

70

Comparison of Casting Materials](https://image.slidesharecdn.com/bakicompletedreport-190214050930/85/Civil-Engineering-Practicum-Report-135-320.jpg)