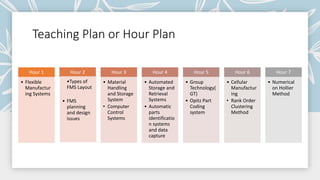

This document outlines the syllabus for the unit on Computer Integrated Manufacturing (CIM) in a mechanical engineering course. The unit covers:

1. Flexible manufacturing systems (FMS) including components, types of layouts, and planning/design issues.

2. Material handling and storage systems, their applications, benefits, and computer control.

3. Group technology/cellular manufacturing concepts like part families/coding, composite parts, machine cell design, and quantitative analysis methods like rank order clustering.