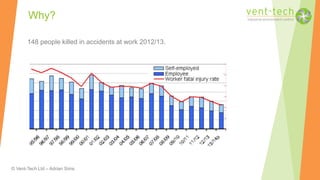

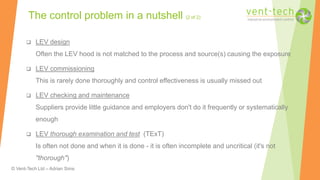

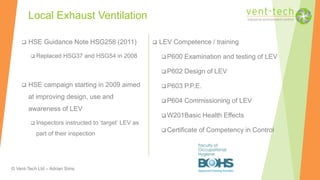

This document provides an overview of a presentation on understanding and designing local exhaust ventilation (LEV) systems. It discusses why LEV is important for health and safety reasons, providing statistics on occupational illness and costs. It also covers relevant legislation, examples of LEV systems, and highlights issues with many current LEV installations. The presentation aims to help attendees properly assess risks, select, commission and maintain LEV controls as required by regulations.