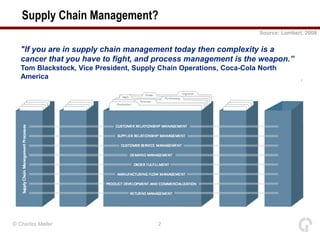

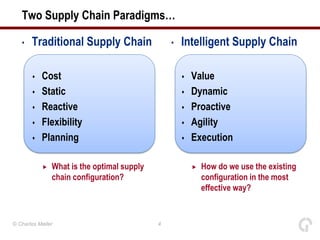

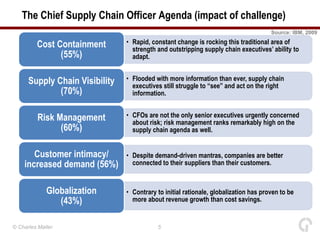

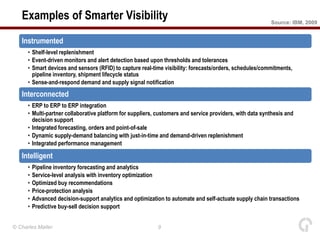

The document discusses the evolution and need for intelligent supply chains, emphasizing the shift from traditional to proactive and dynamic models that enhance visibility, risk management, and customer interaction. It outlines the challenges faced by supply chain executives, the benefits of interconnected systems, and examples of smarter practices utilizing advanced technologies. Additionally, it highlights opportunities for Danish SMEs to optimize their operations within global supply chain networks through collaboration and innovation.