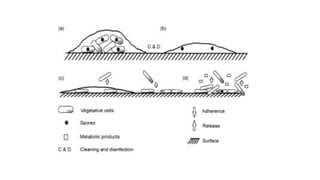

The document discusses the importance of hygienic practices throughout the milk processing chain to ensure quality and safety. It emphasizes the need for good agricultural and manufacturing practices, along with the application of HACCP to manage hazards and prevent contamination. Future trends include the introduction of automatic milking systems and shifts towards process control rather than solely end-product testing.