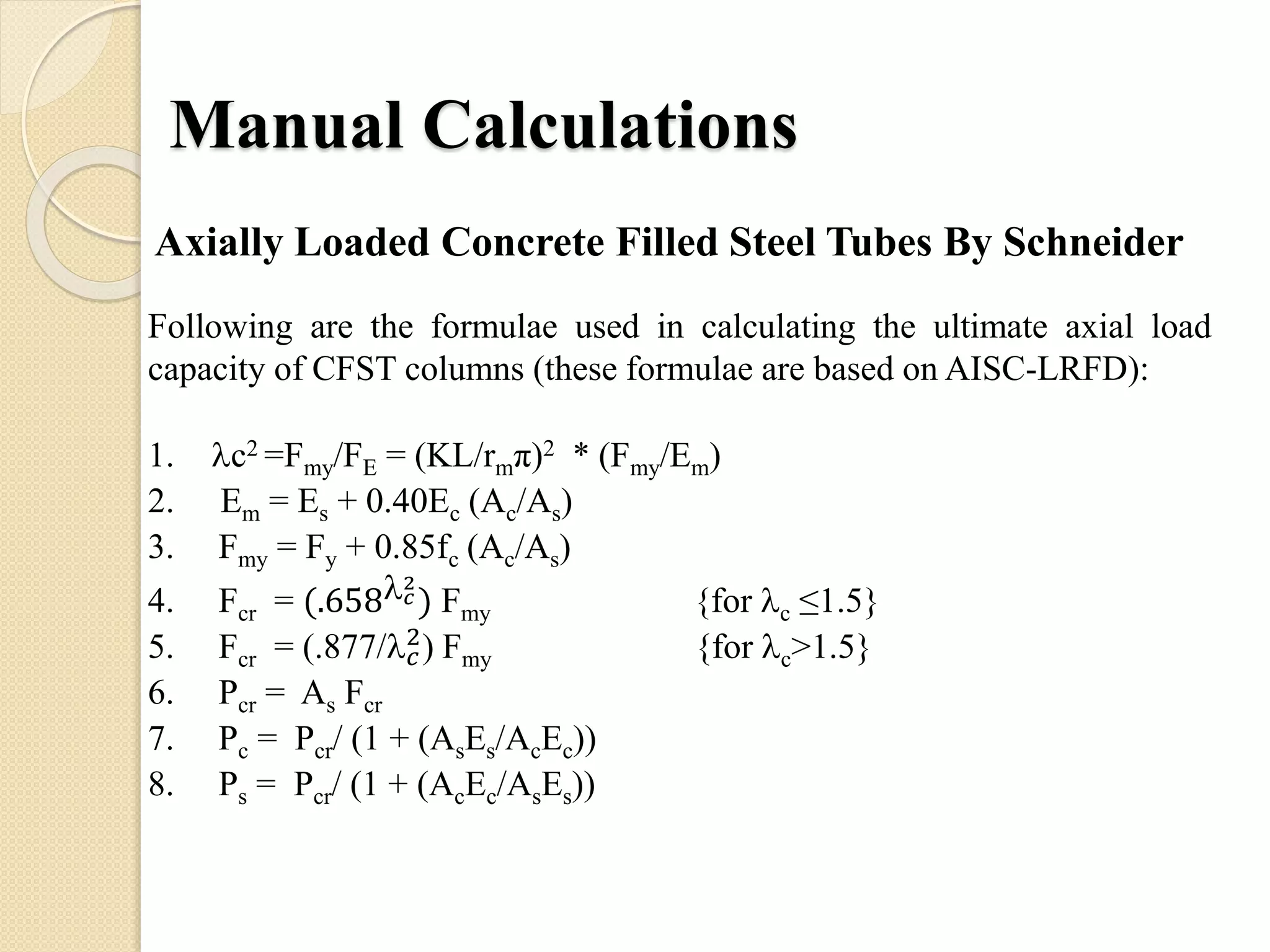

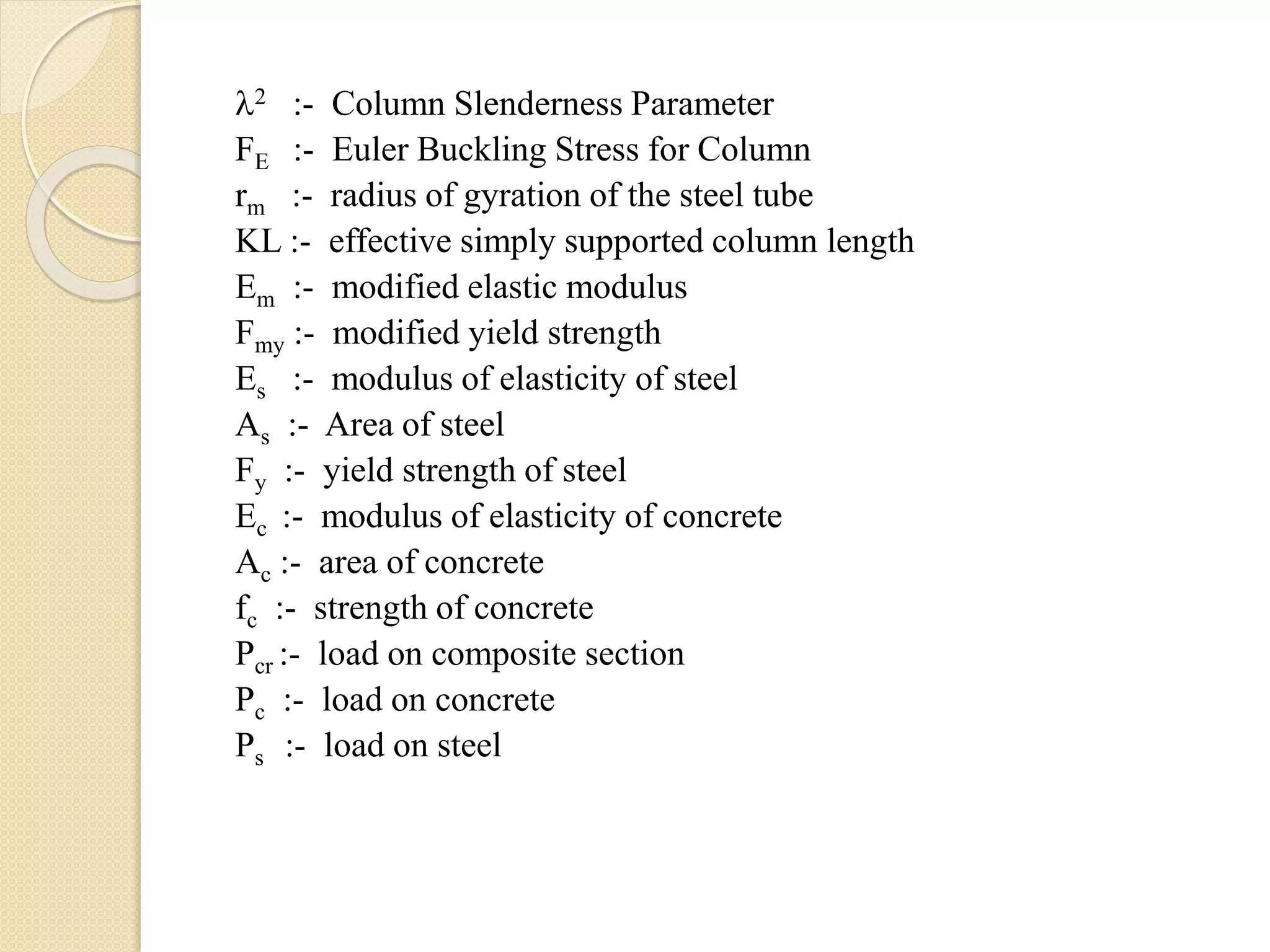

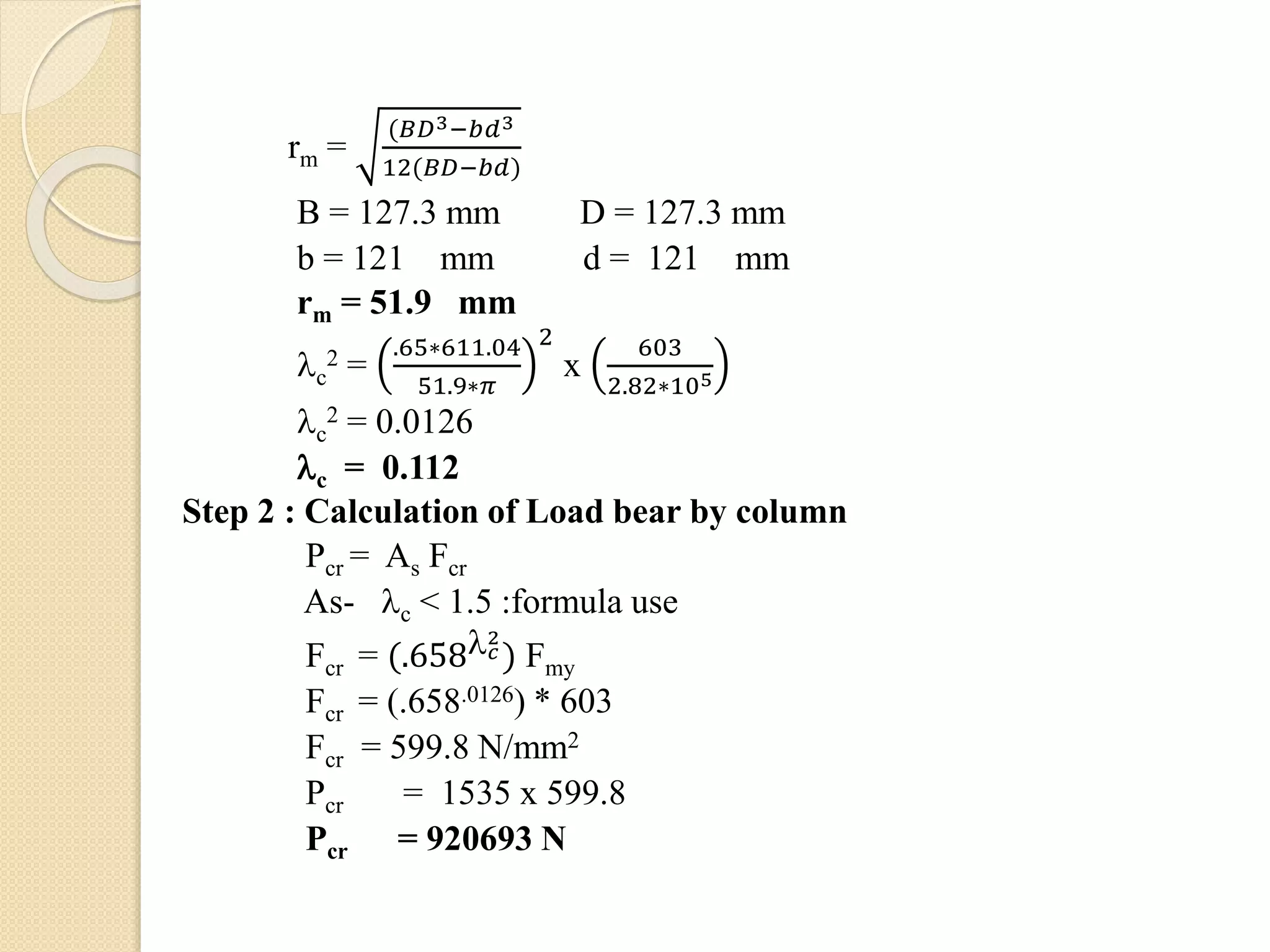

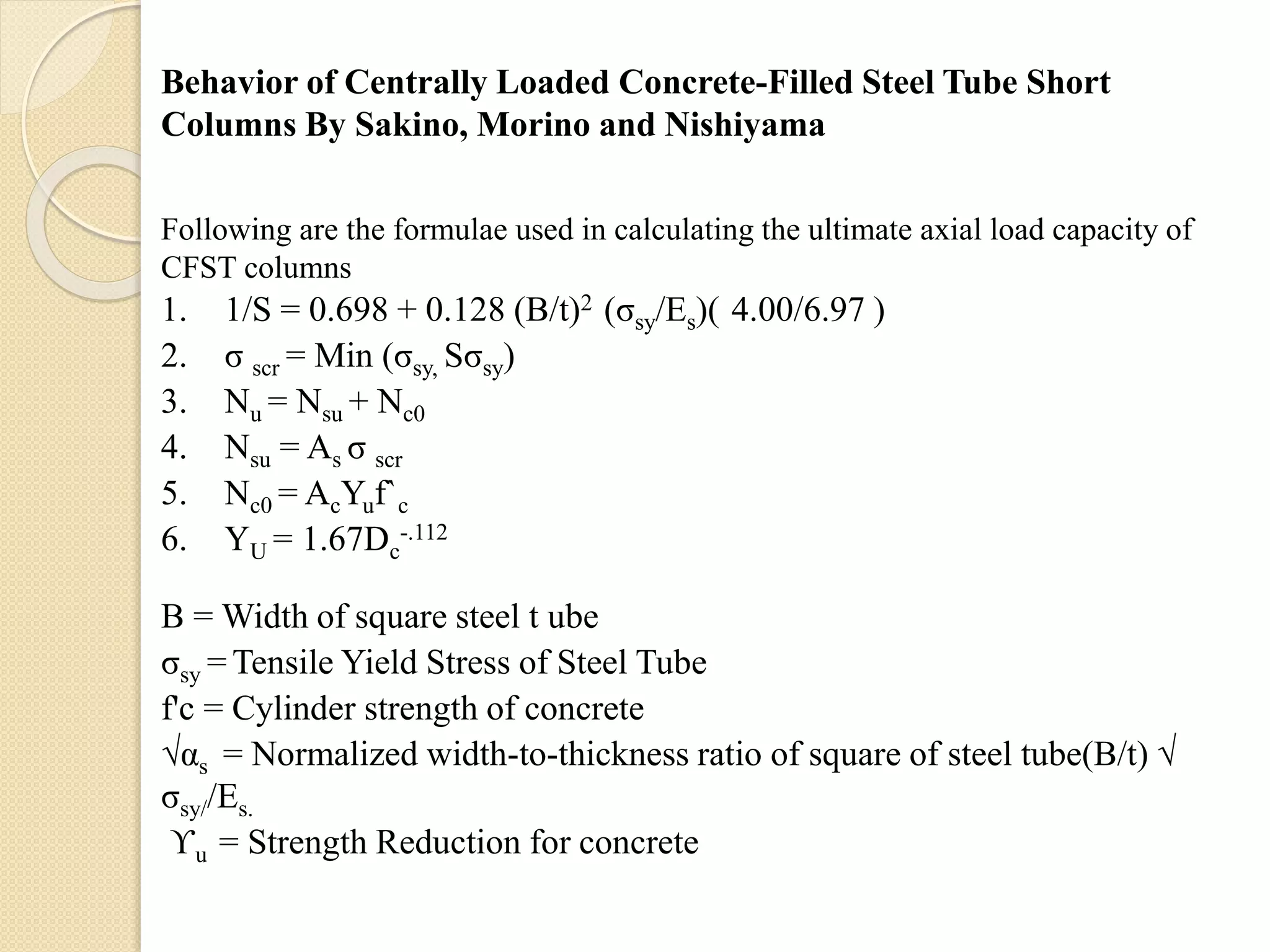

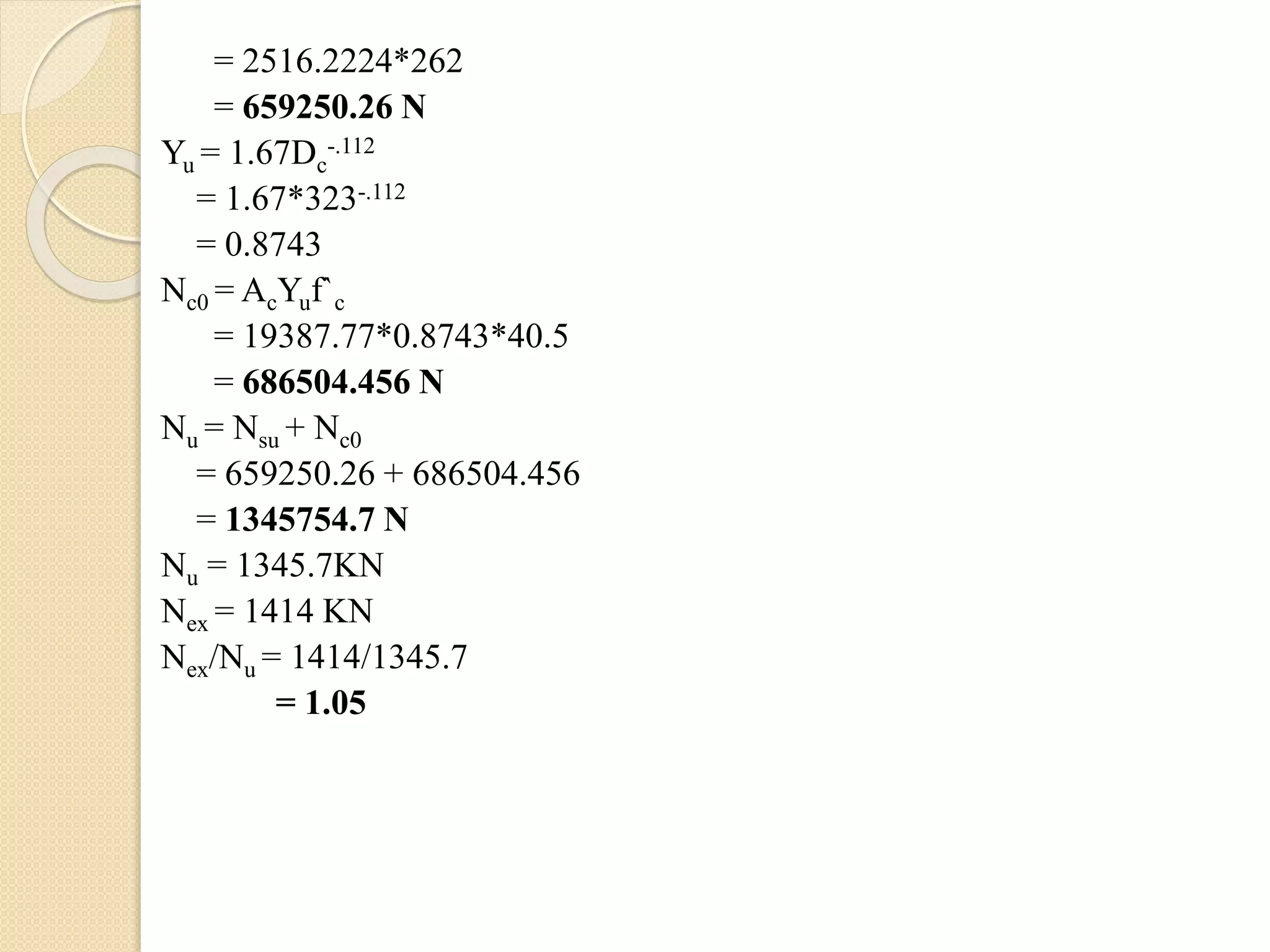

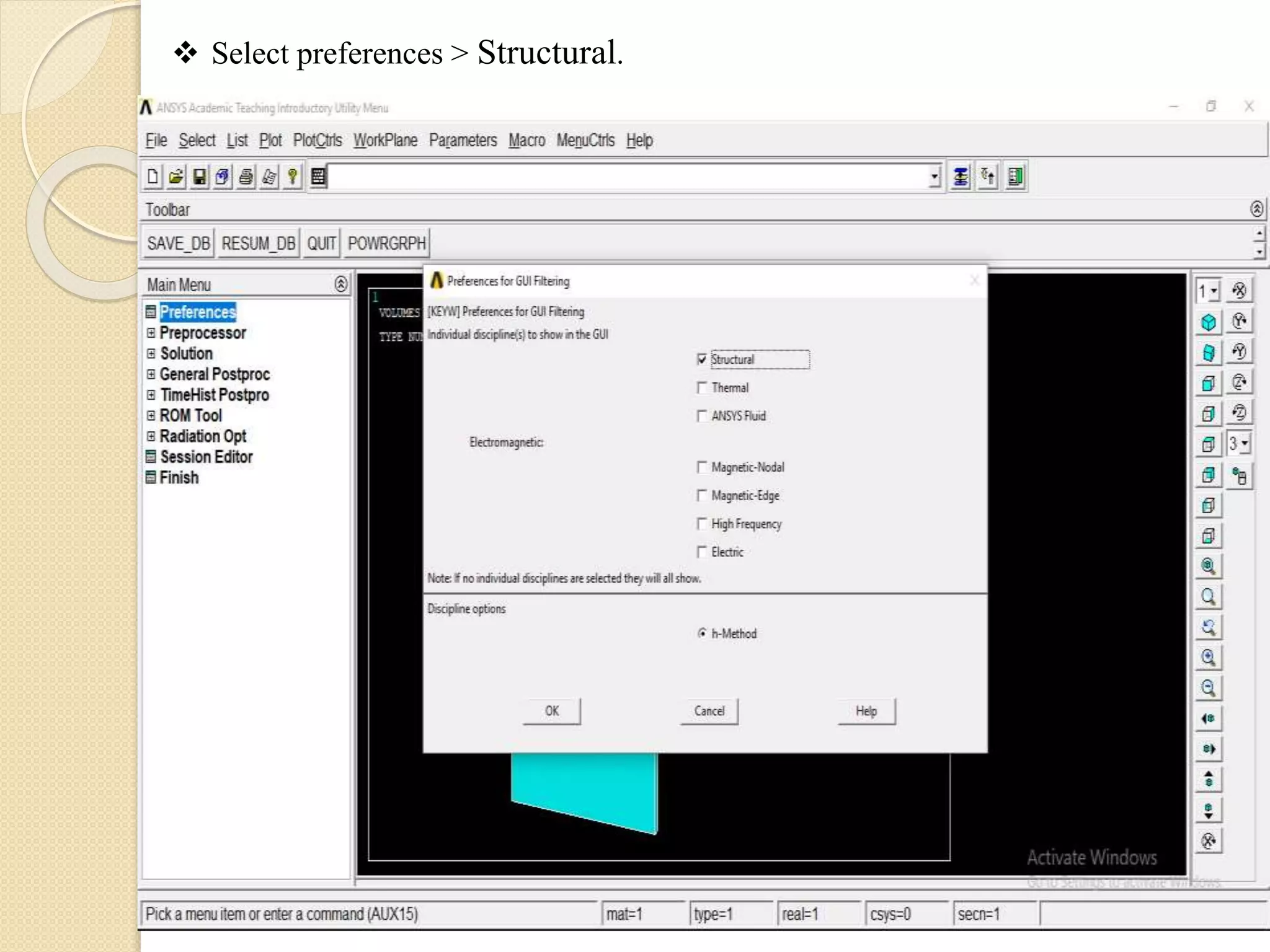

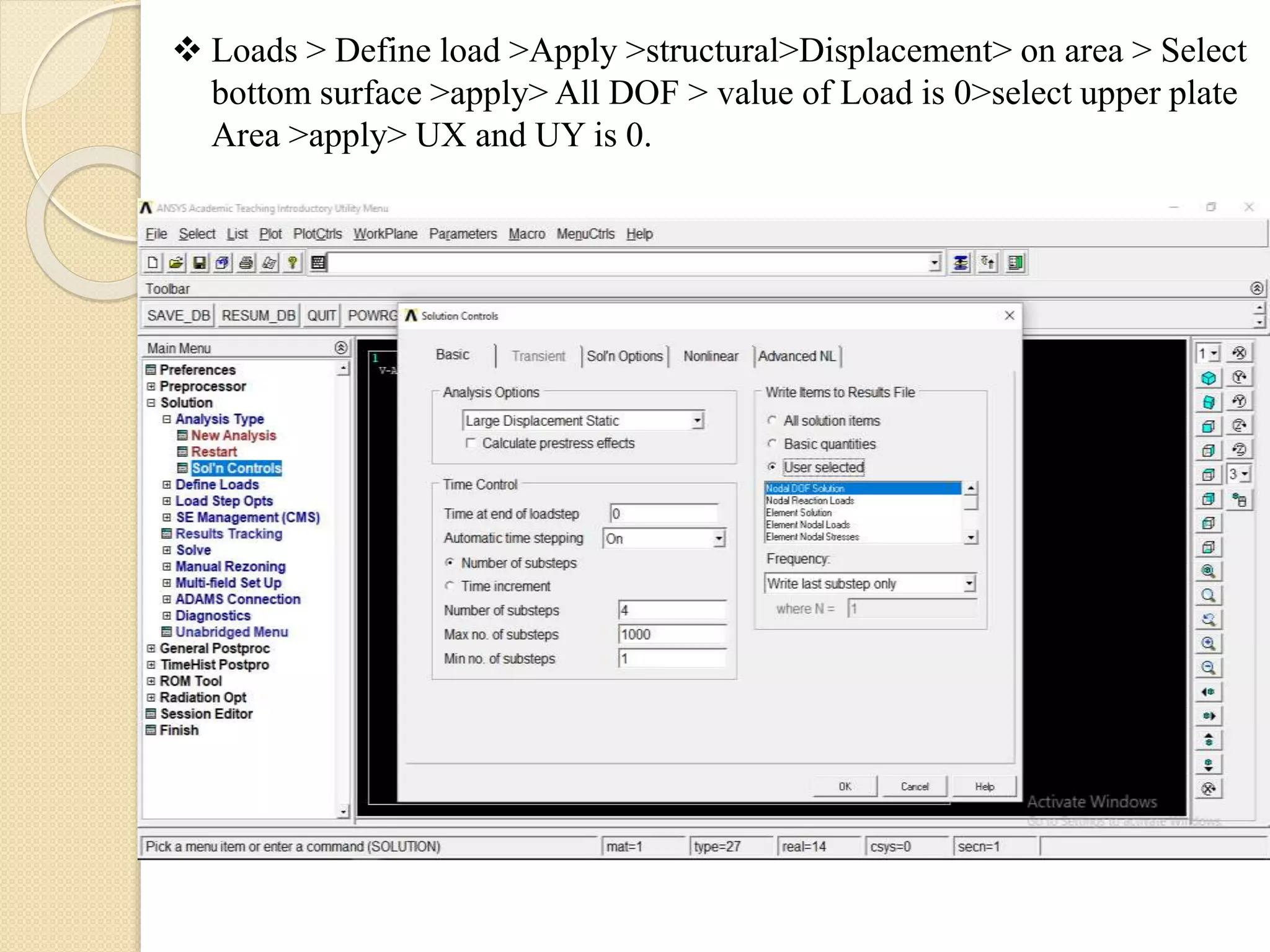

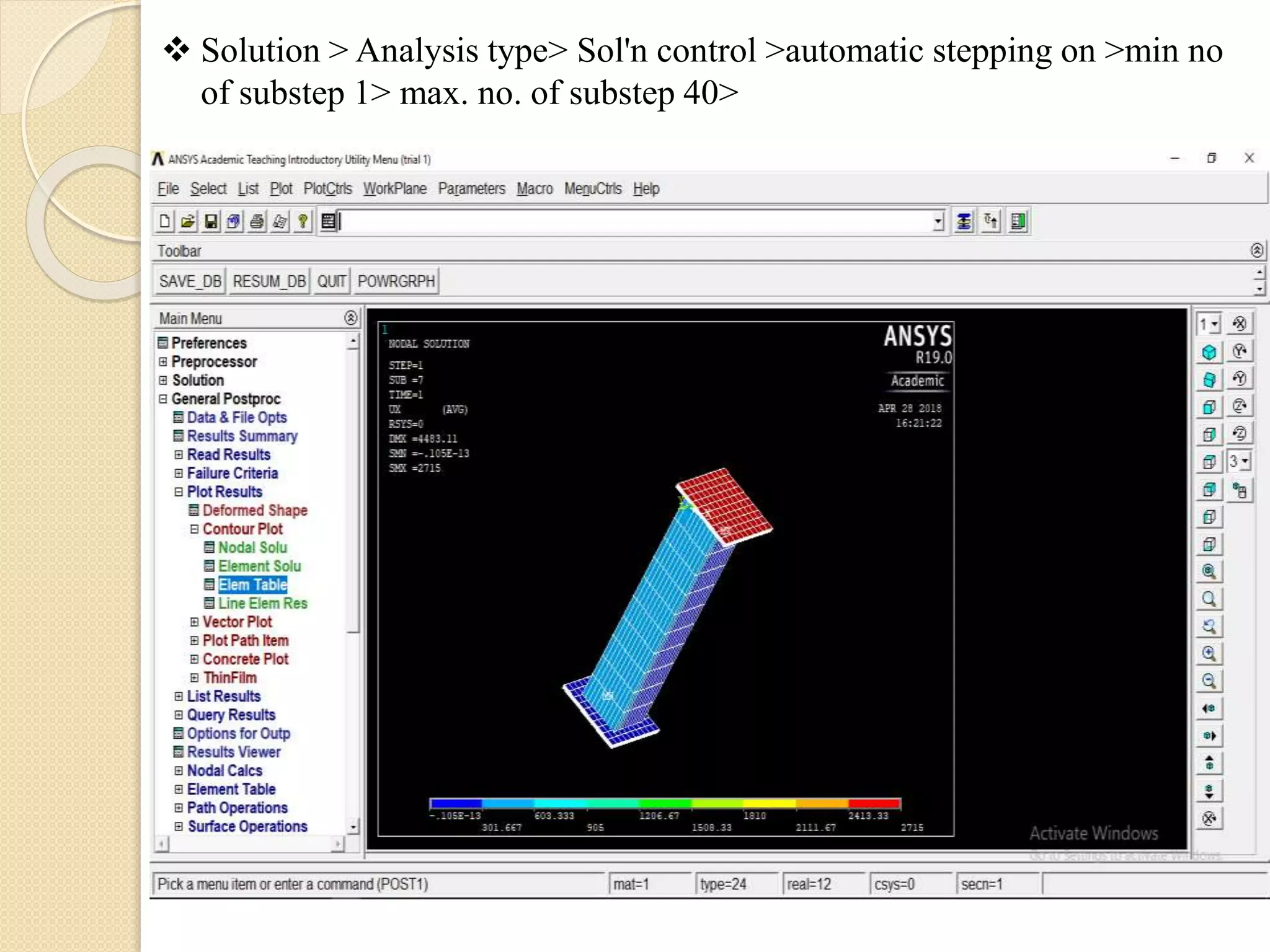

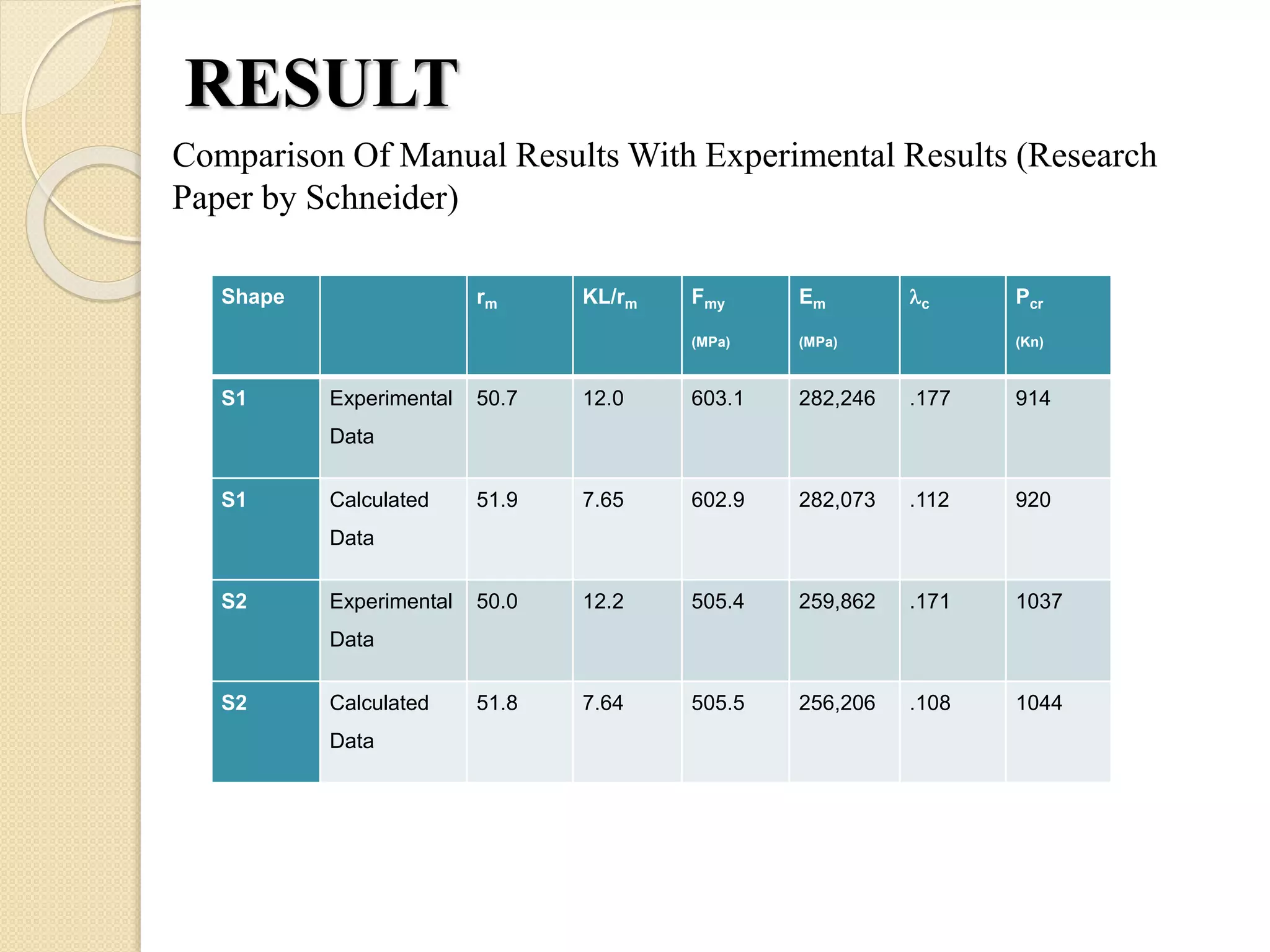

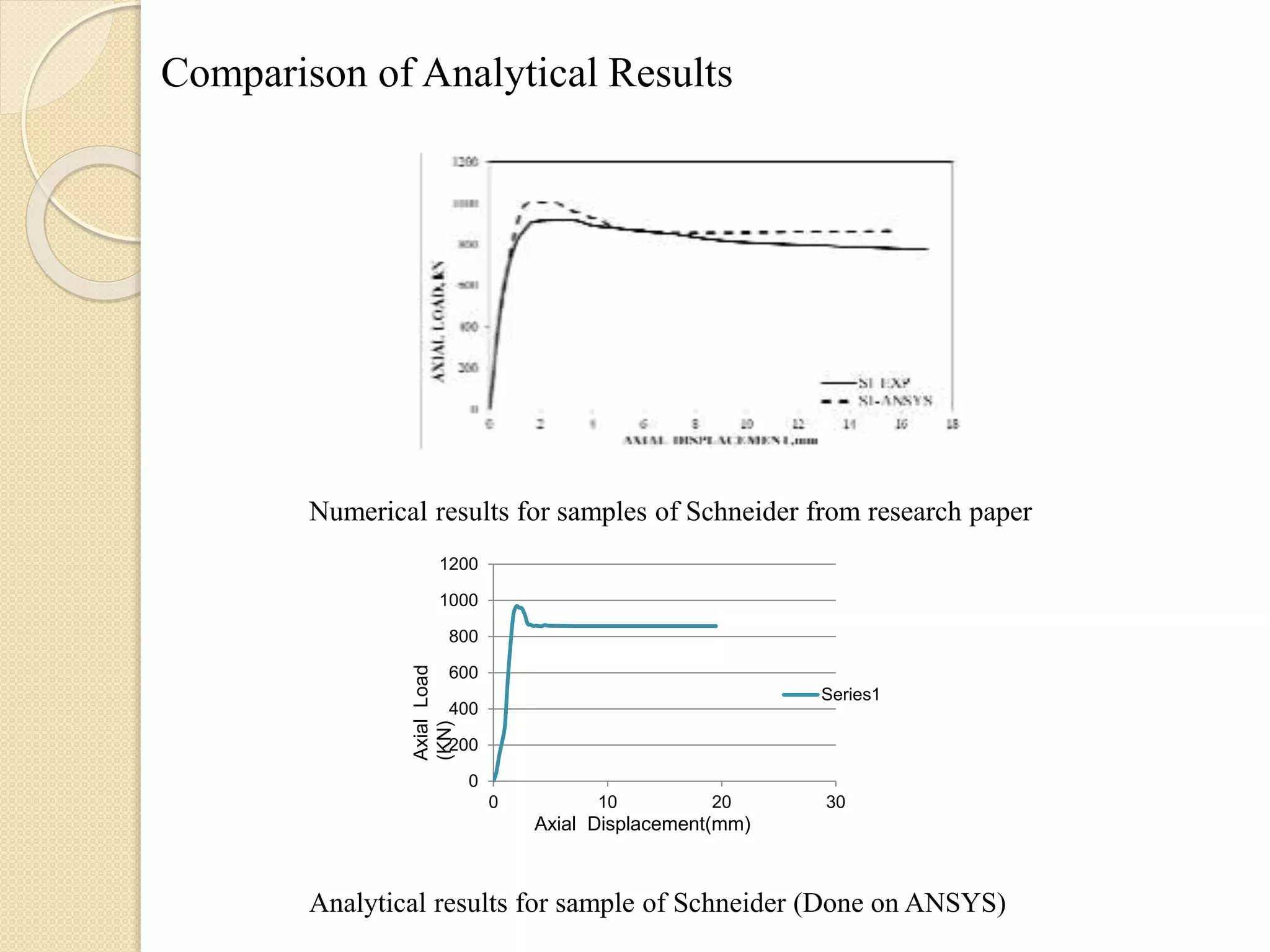

The document presents a study on the validation of concrete filled steel tubular columns using both manual calculations and ANSYS simulations. It includes detailed procedures for calculating the ultimate axial load capacity and comparisons between analytical and experimental results for various specimens. The findings highlight the effectiveness of the methodologies used, with results showing minor discrepancies between experimental and analytical values.