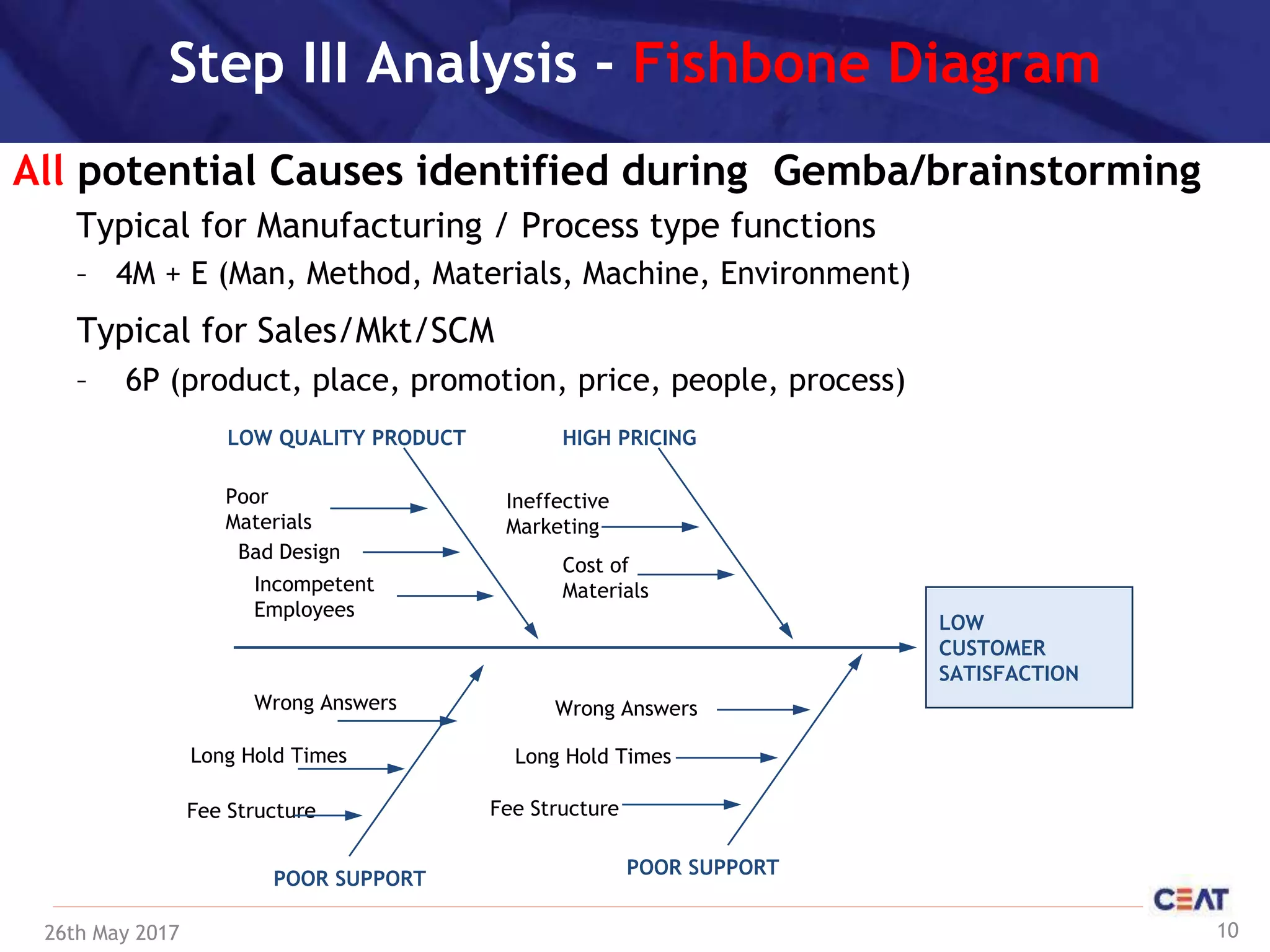

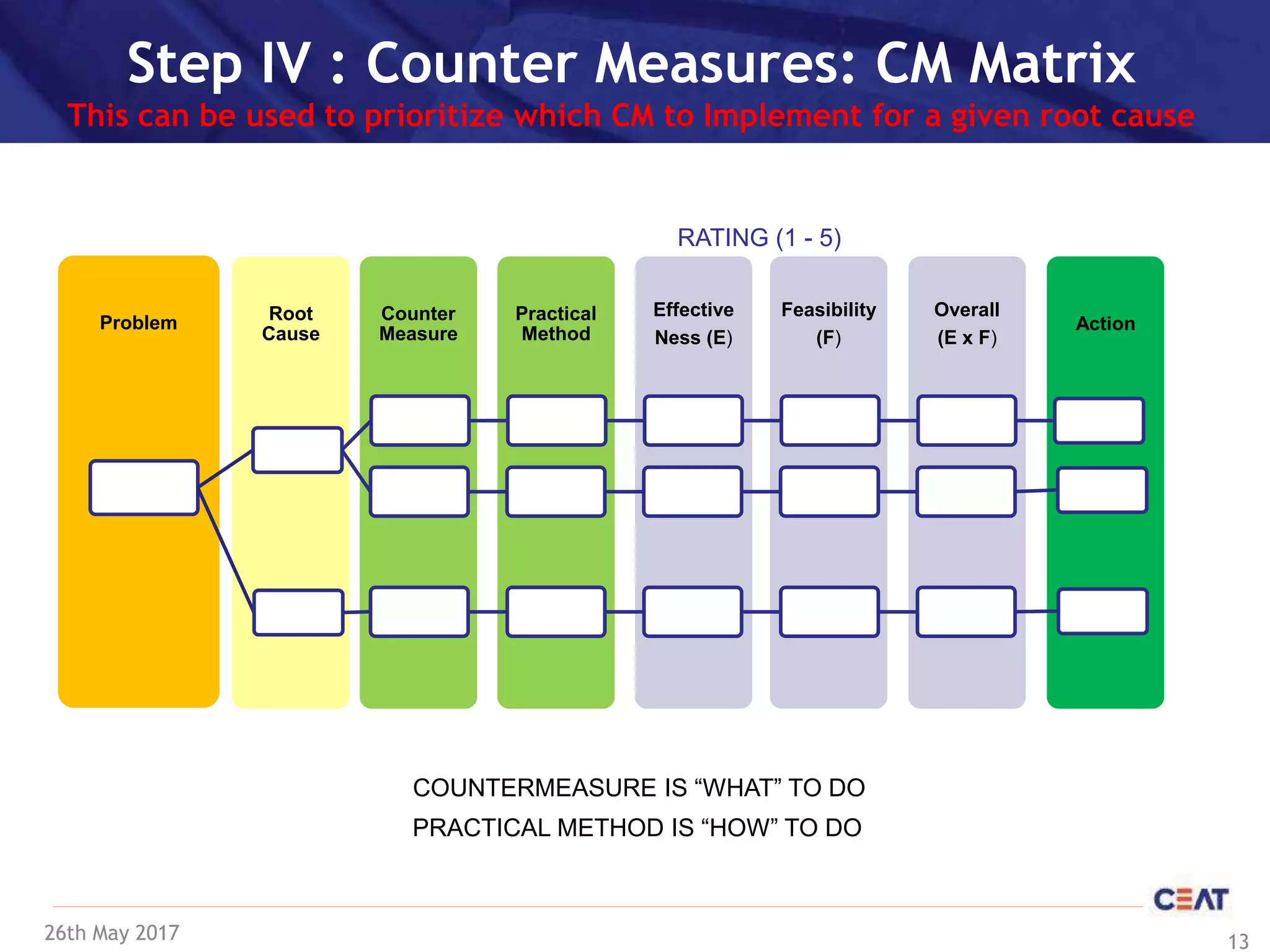

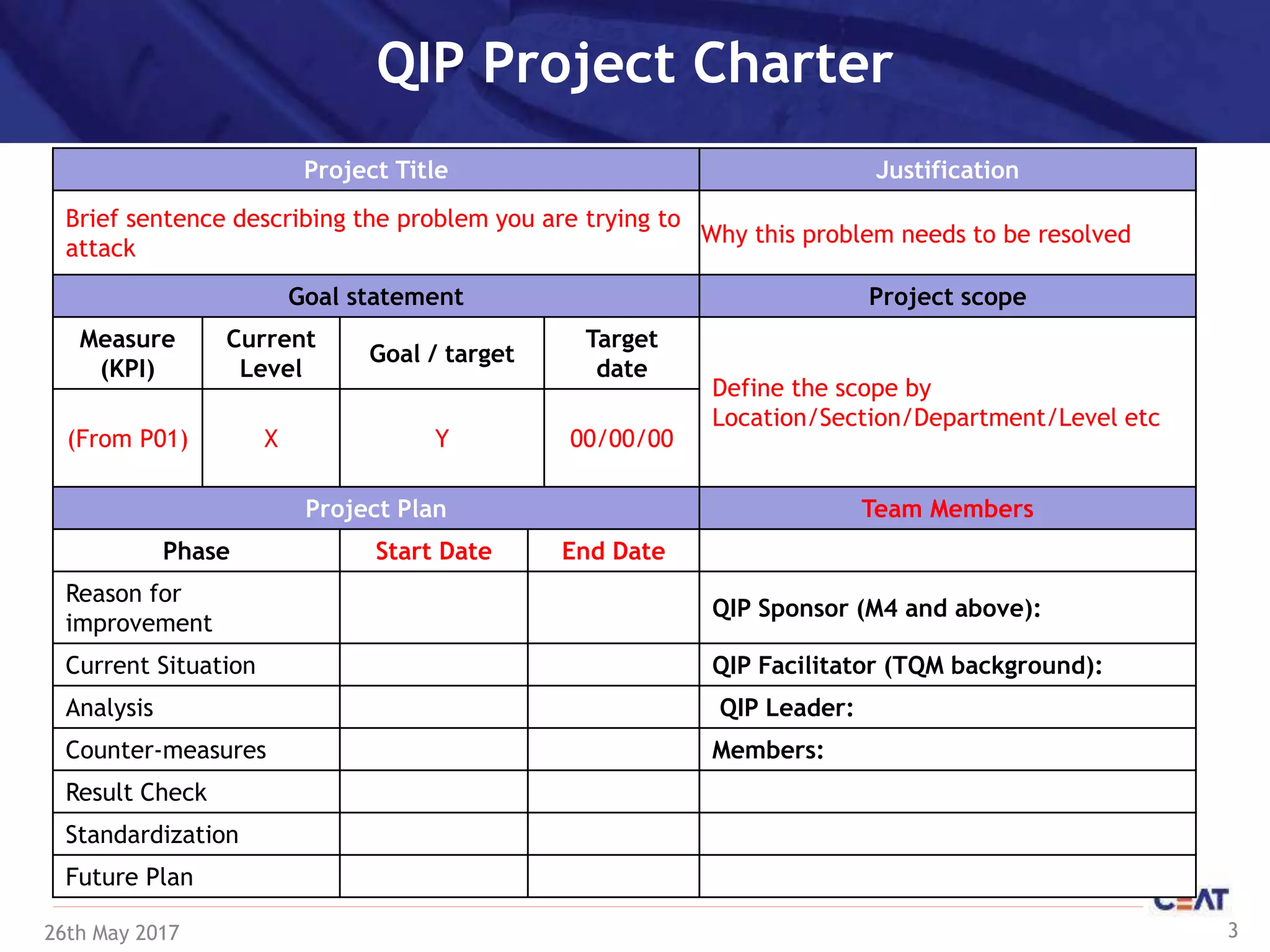

Project aims to reduce radial side wall rejections in bias cutting. [Step I] identifies the current high level of side wall rejections as the problem area and validates the need for improvement. [Step II] analyzes current processes through data collection and identifies the specific problem as reducing defects in SKU X from Y% to Z% by date. [Step III] uses a fishbone diagram and validation to identify root causes such as machine issues and lack of training. [Step IV] develops a countermeasure matrix to prioritize solutions and an action plan to address root causes. [Step V] checks results through before/after data showing benefits. [Step VI] standardizes improvements through updated documents. [Step VII]

![Step II Current Situation

Adherence-To-Standard Check Table

Sl. No. Cause(s) of pain area

Are there

existing

standards

(SOP/WI etc)

[Yes/No]

If yes, what are the

standards?

[Name]

Are the

standards

currently

followed?

[Yes/No]

Reason, if not followed

Will the pain

area be

eliminated if

standards are

followed?

[Yes/No/Maybe]

Action

Planned on

Standard

[Create

/Follow/

Modify]

– If any Action item is ‘Follow Standard’, then first follow the

standard and validate whether the pain area still exists

– If all action items are either ‘Create’ or ‘Modify’, then continue

to forming the ‘Specific Problem Statement’

Validation of Pain Area

826th May 2017](https://image.slidesharecdn.com/ceatqipreporttemplate-180228110413/75/Ceat-qip-report-template-8-2048.jpg)