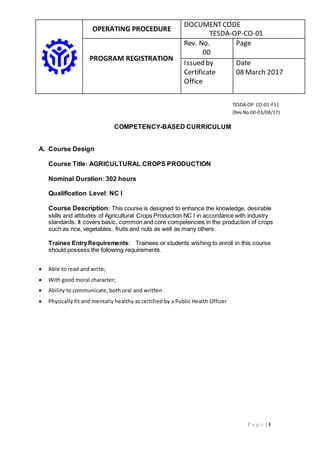

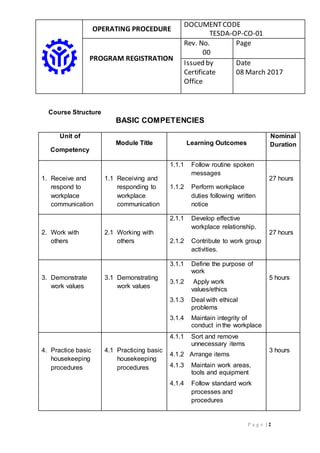

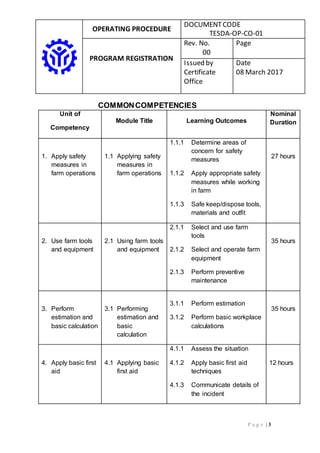

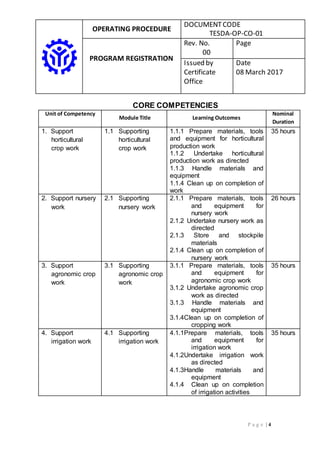

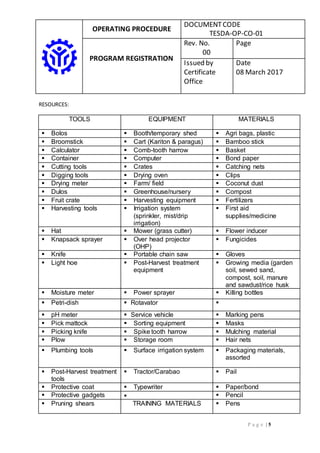

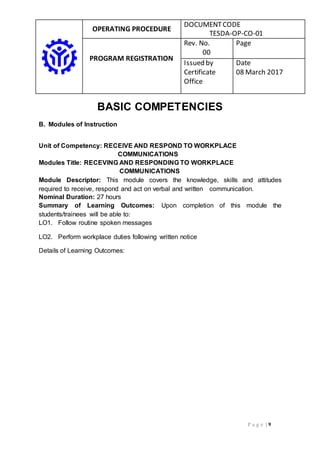

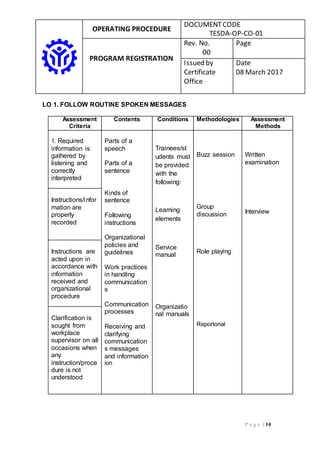

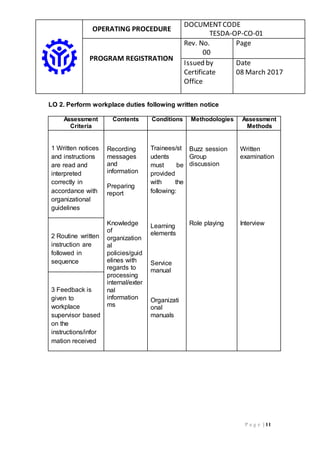

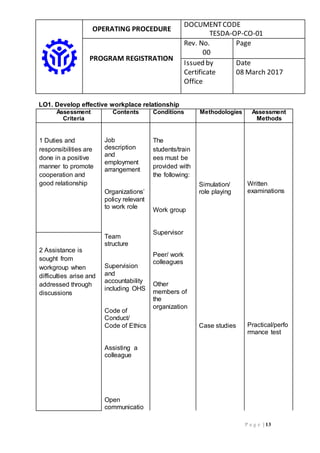

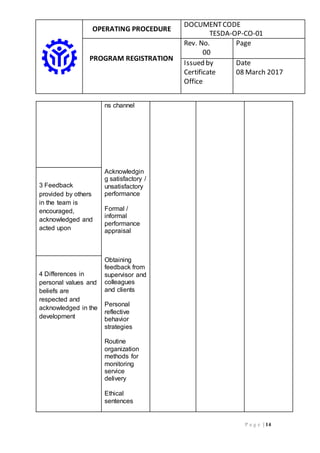

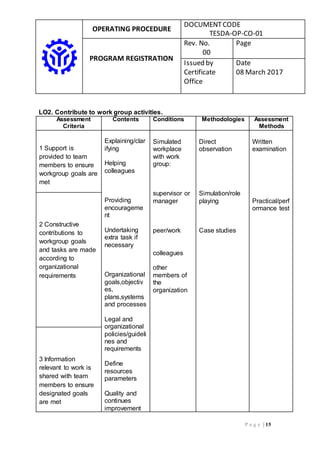

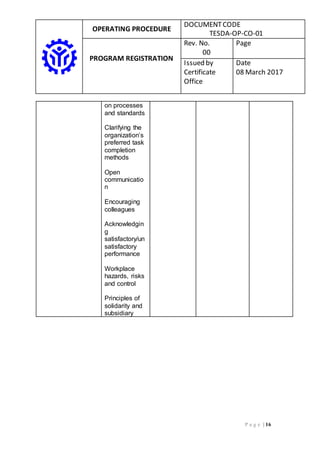

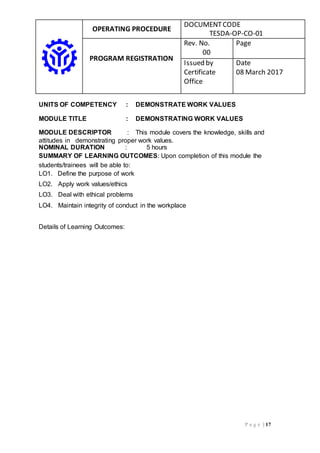

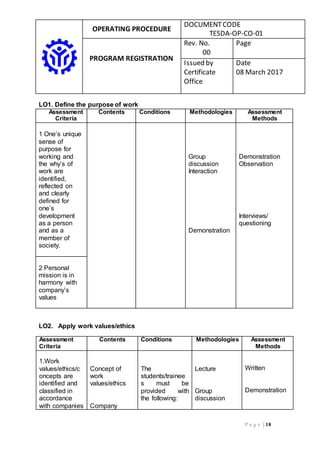

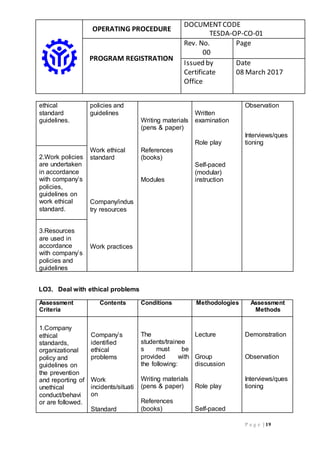

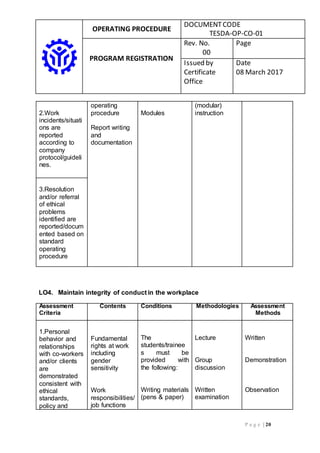

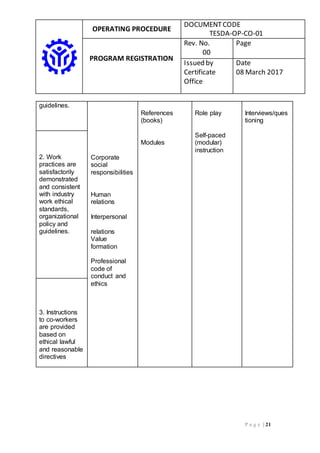

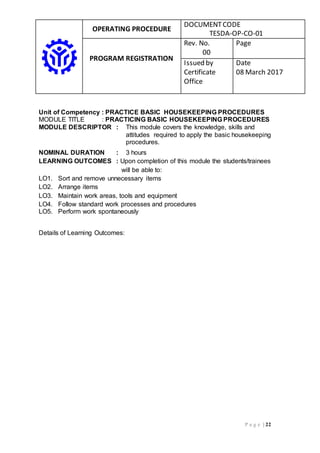

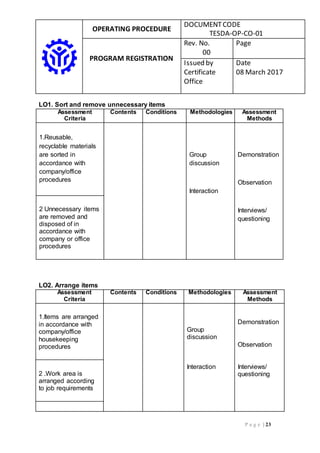

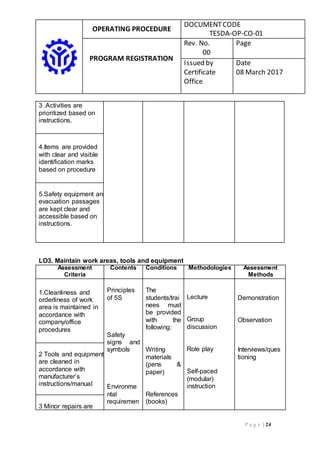

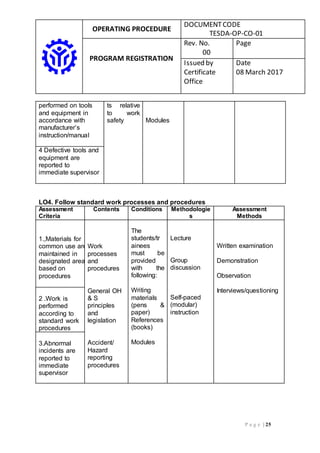

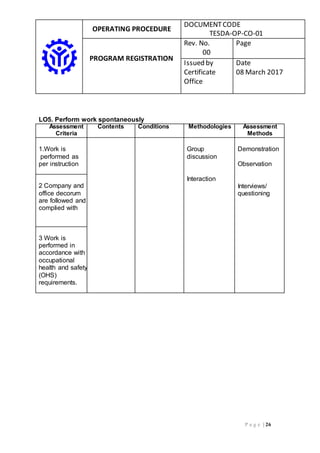

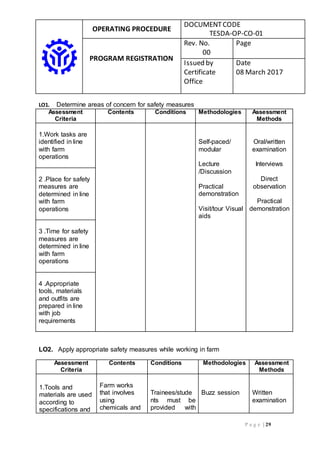

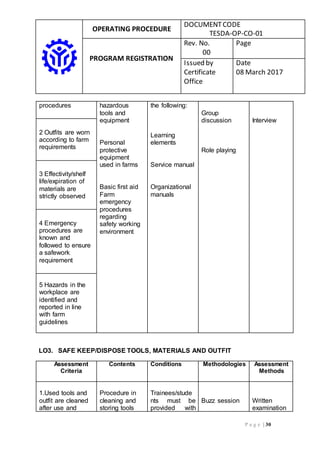

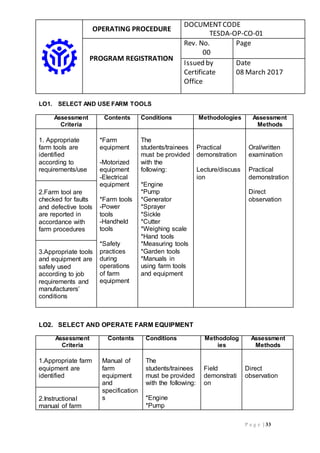

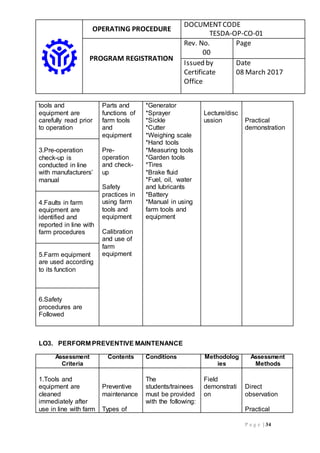

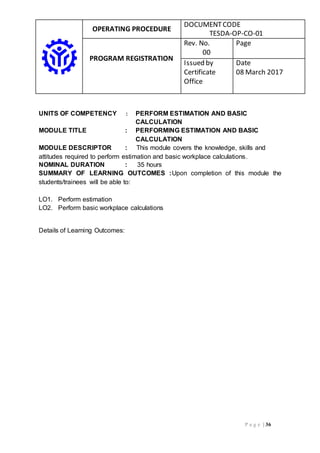

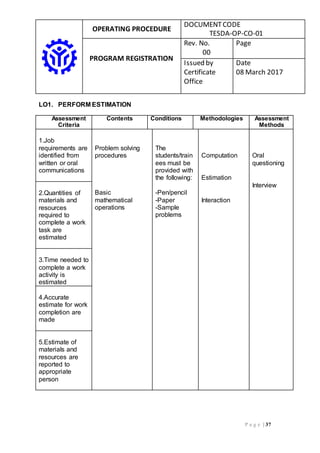

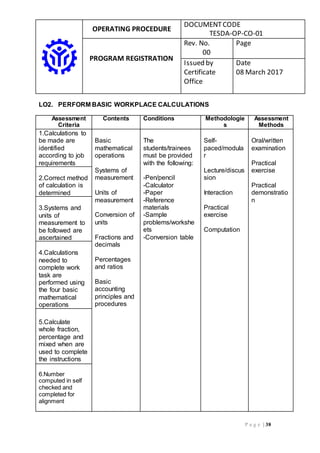

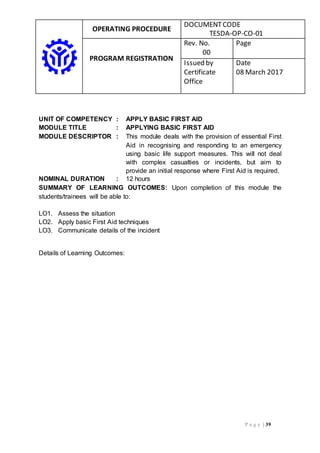

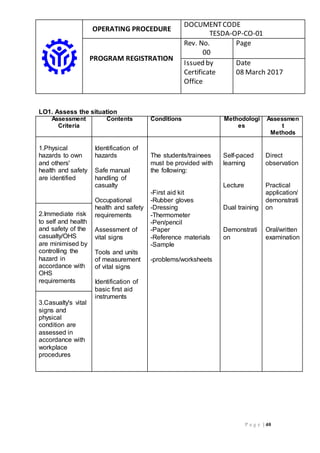

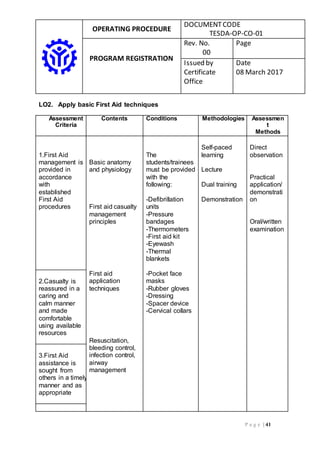

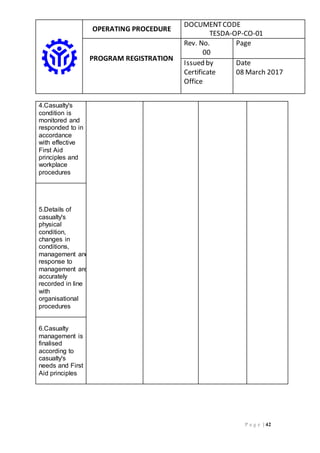

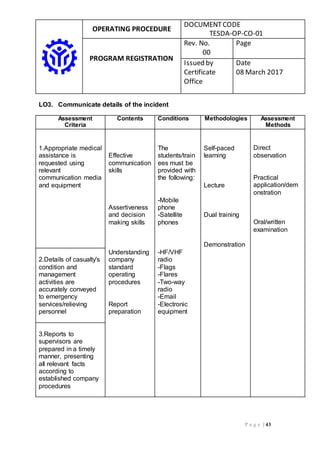

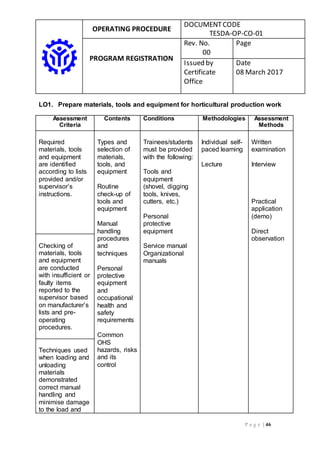

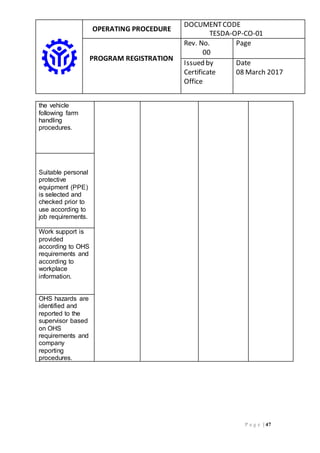

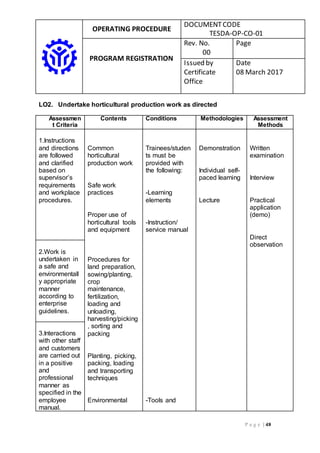

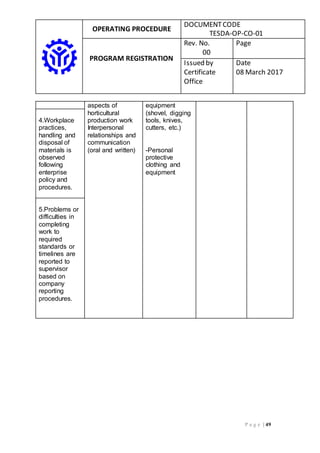

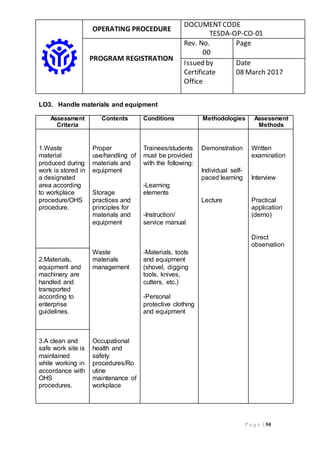

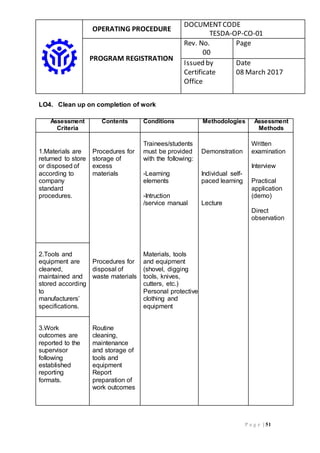

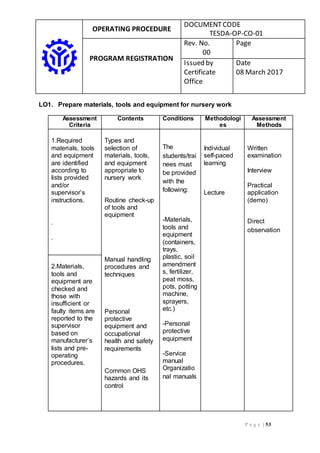

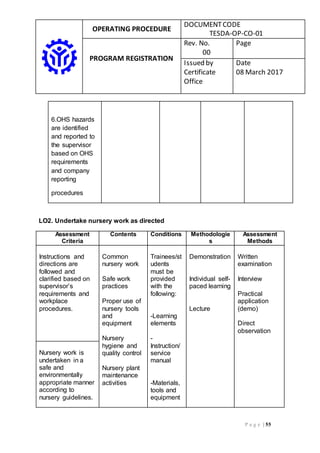

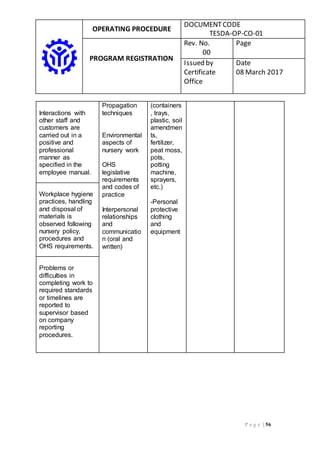

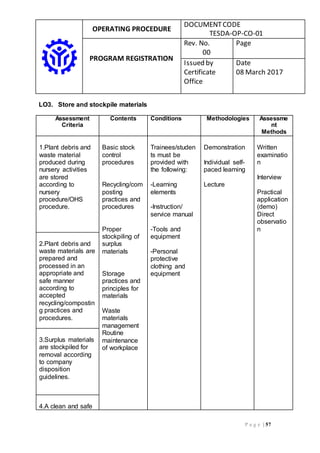

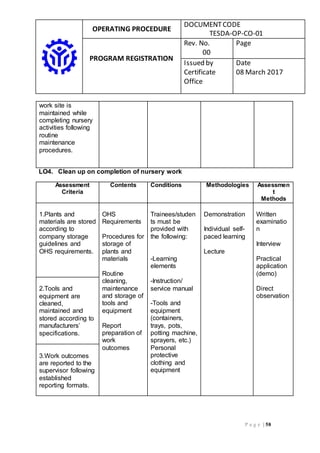

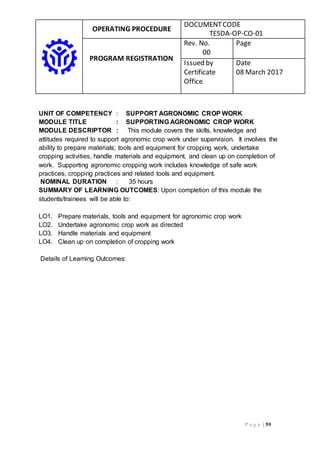

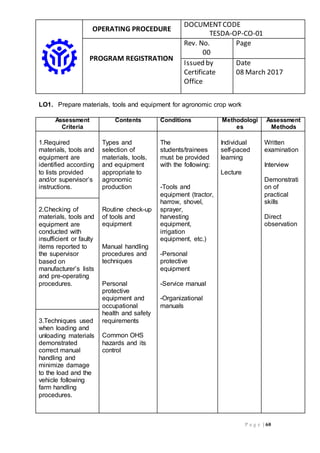

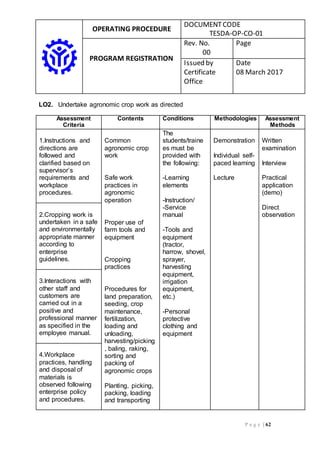

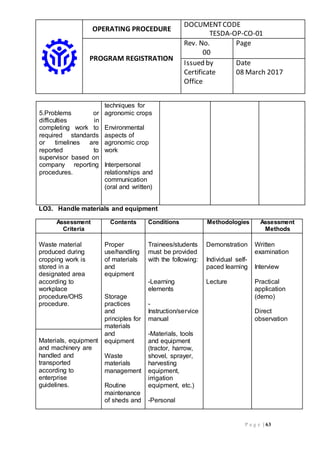

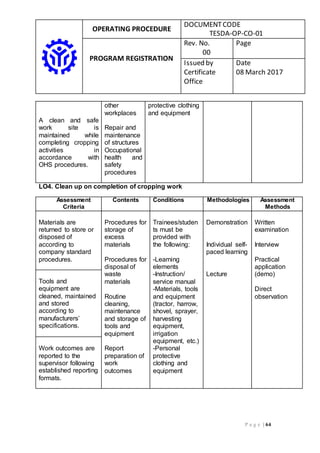

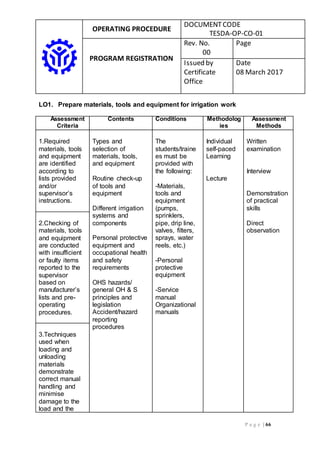

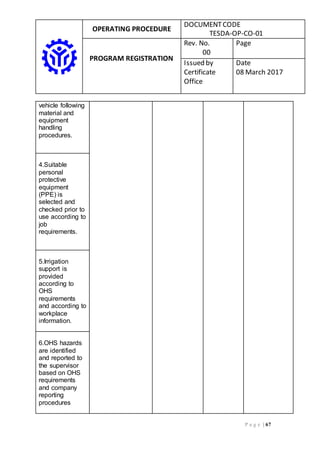

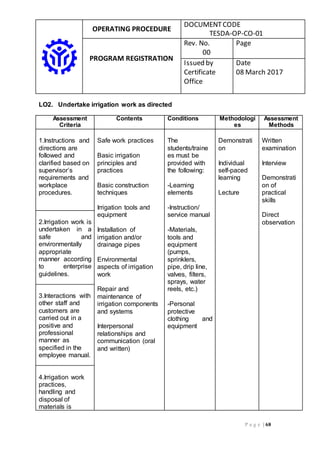

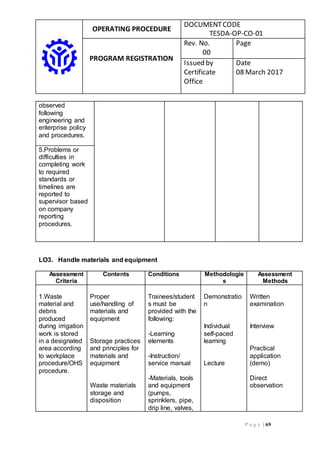

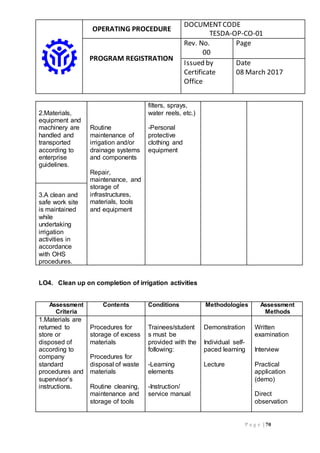

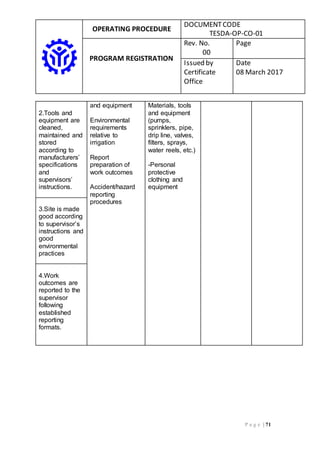

The document outlines an operating procedure for a competency-based curriculum for an Agricultural Crops Production course. It details the course description, entry requirements, structure including basic, common and core competencies. It also lists the learning outcomes, assessment criteria, resources and modules of instruction for the course. The course is designed to enhance skills and knowledge of agricultural crop production according to industry standards.