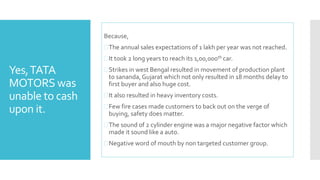

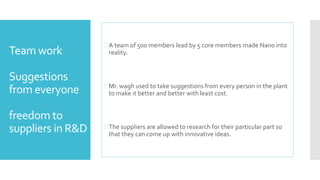

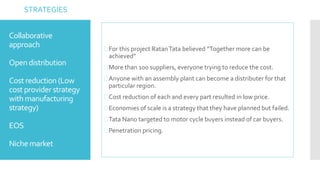

Tata Motors established the Tata Nano as the world's cheapest car through a collaborative approach. They broke down the car components and outsourced manufacturing to over 100 suppliers, such as Bosch, to reduce costs. This allowed suppliers to innovate and helped Tata Motors produce the Nano for under Rs. 100,000. However, Tata Motors struggled to meet sales targets of the Nano due to production delays from strikes and negative publicity from fires, limiting their ability to capitalize on the initial hype around the affordable "people's car."