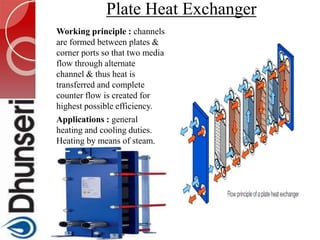

The document is an industrial training presentation on Thermax heater operation and maintenance at Dhunseri Petrochem Limited in Haldia, West Bengal. It provides information about the company, which manufactures PET resin using German technology. It describes the raw materials and two-step process used. It then details some key equipment used - the bucket elevator, hot water pump, plate heat exchanger, Cyclomax, and bag filter. Finally, it discusses maintenance of the Thermax heater and its components to ensure efficiency and prevent breakdowns.

![INDUSTRIAL TRAINING PRESENTATION

ON

THERMAX HEATER OPERATION & maintenance

COMPILED BY-

RISHABH SINGH

[ ME,4TH YR ]

At

Dhunseri Petrochem Limited,

Haldia ,

West Bengal](https://image.slidesharecdn.com/6c77c83e-974e-42cb-ba95-ba3fe4e4addf-161011073254/85/DPL-1-320.jpg)