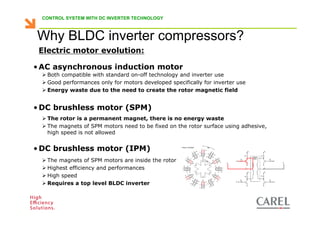

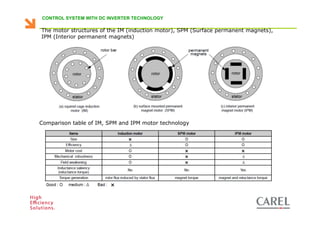

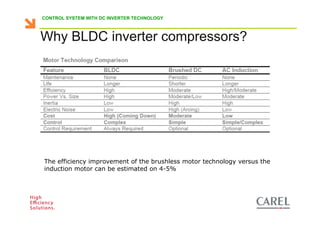

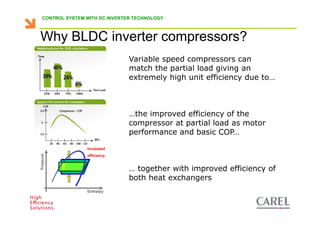

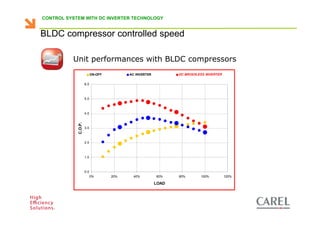

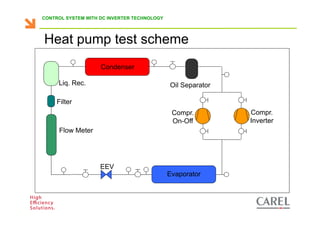

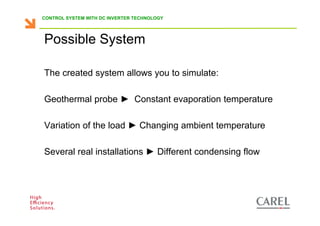

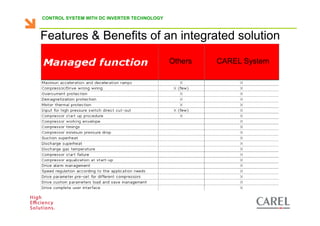

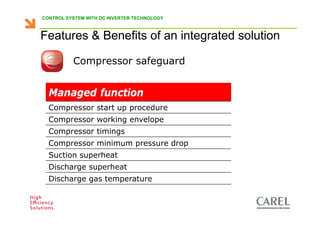

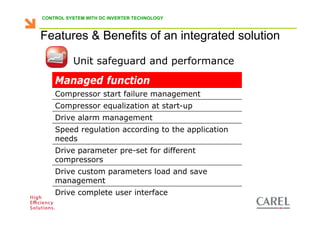

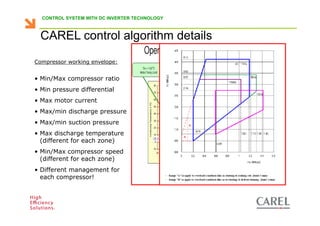

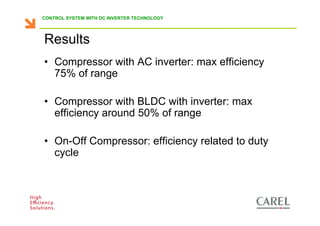

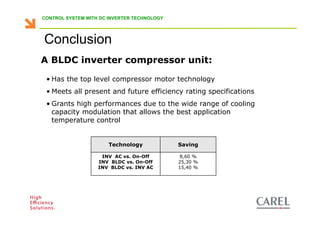

The document discusses control systems for heat pumps using DC inverter technology. It describes developing a control algorithm for a heat pump using a brushless DC inverter-driven compressor. It compares the efficiency and performance of traditional on/off compressor technology, AC inverter technology, and the new DC inverter technology. The DC inverter technology provides improved efficiency over AC inverters and traditional systems through more precise capacity control of the compressor.