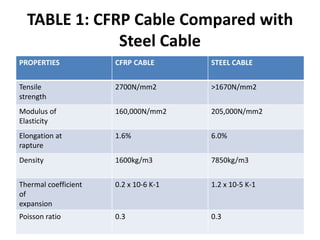

Carbon fibre reinforced polymer (CFRP) cables are used for suspended bridges due to their resistance to corrosion, stress corrosion, fatigue, design faults and production faults. CFRP cables consist of extremely thin carbon fibres embedded in a polymer resin matrix. CFRP cables have higher strength and modulus of elasticity than steel cables, while also having lower density, making them lighter. CFRP cables are increasingly being used in bridges due to advantages like corrosion resistance, light weight, strength, damping characteristics, and resistance to fatigue.