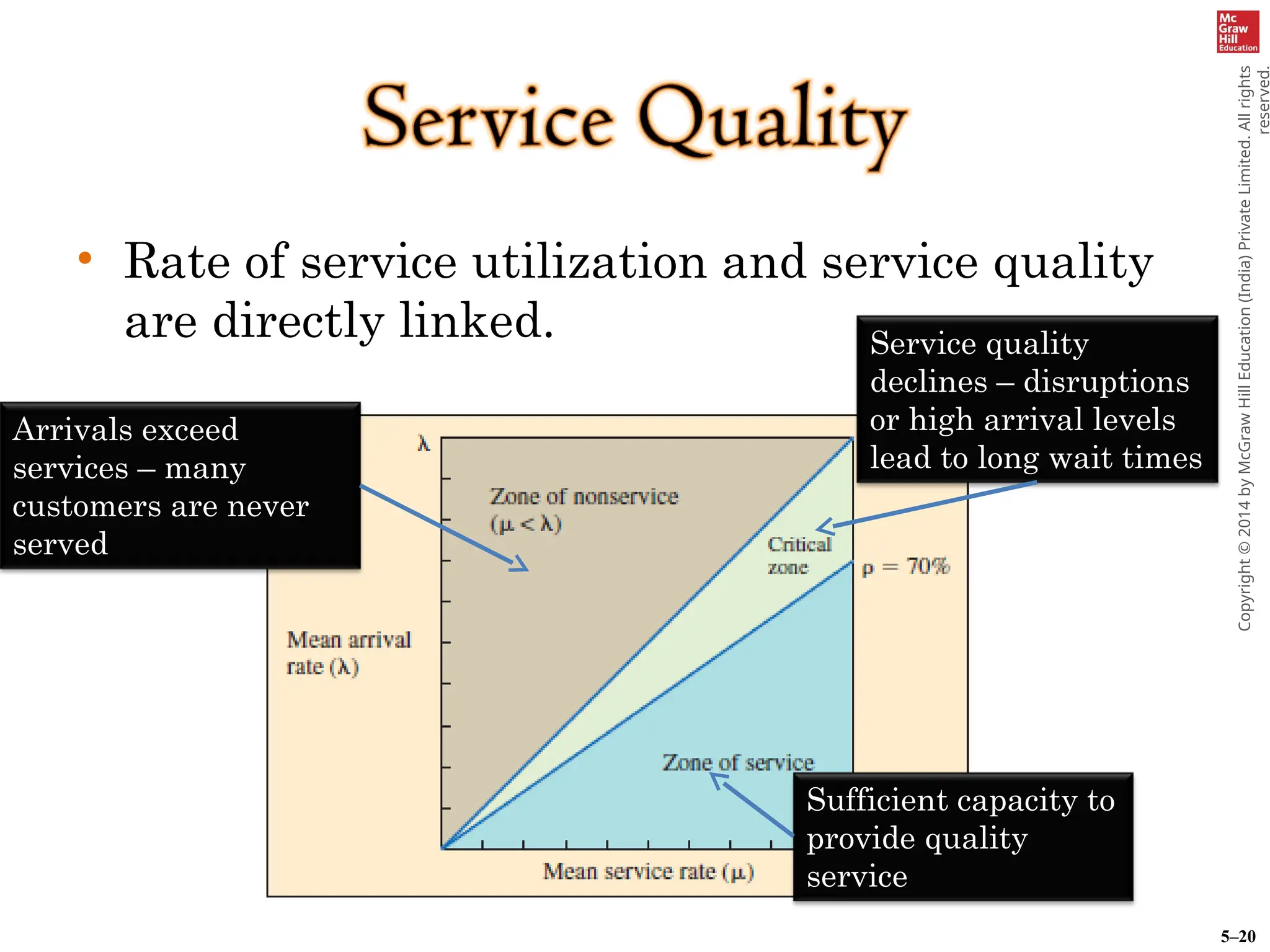

Chapter 5 focuses on strategic capacity management, detailing capacity planning, utilization, economies of scale, and their impact on production efficiency. It emphasizes the relationship between service capacity and service quality, indicating optimal utilization levels based on service context. Key concepts include capacity focus, flexibility, and the importance of aligning capacity requirements with demand forecasts.