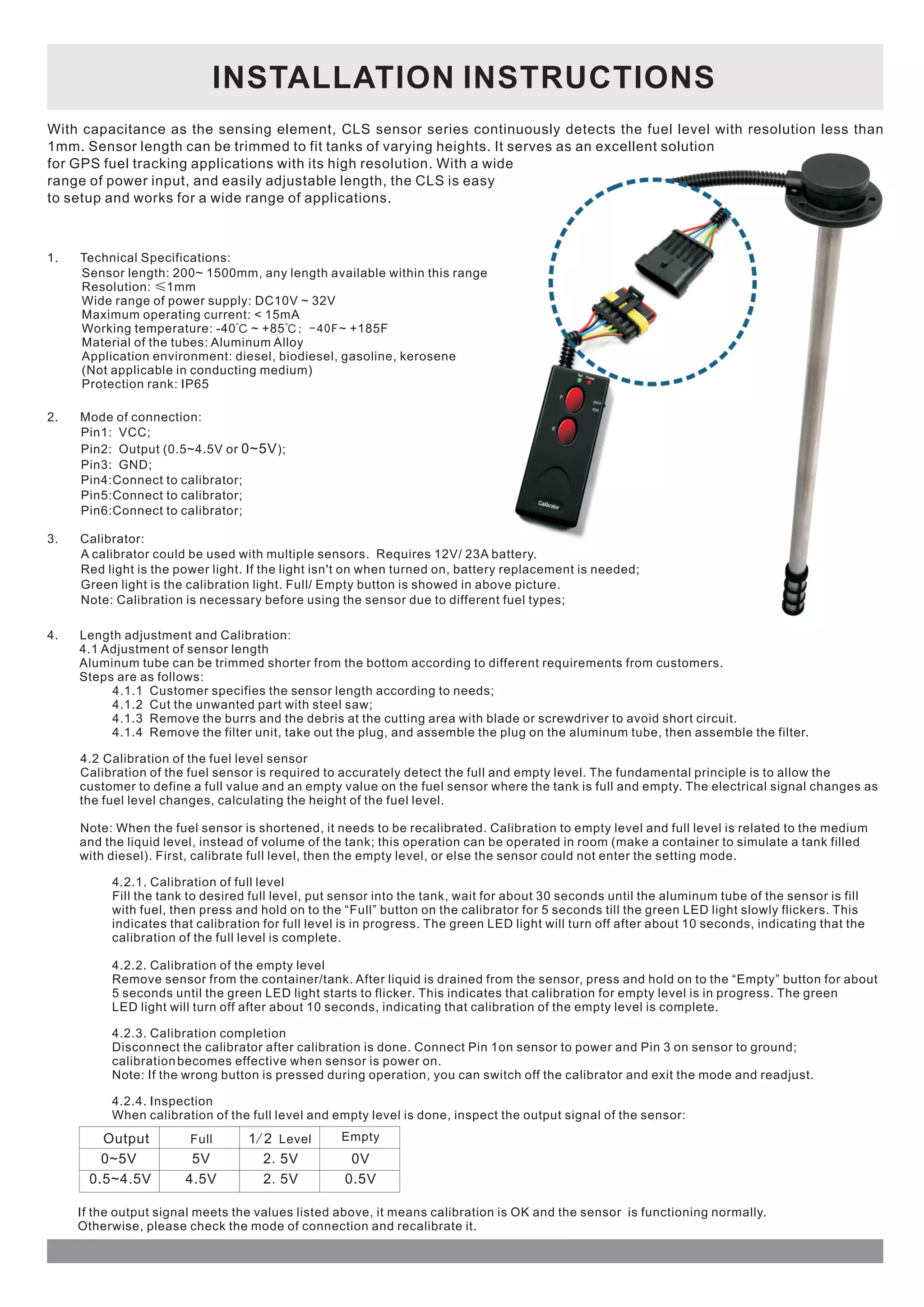

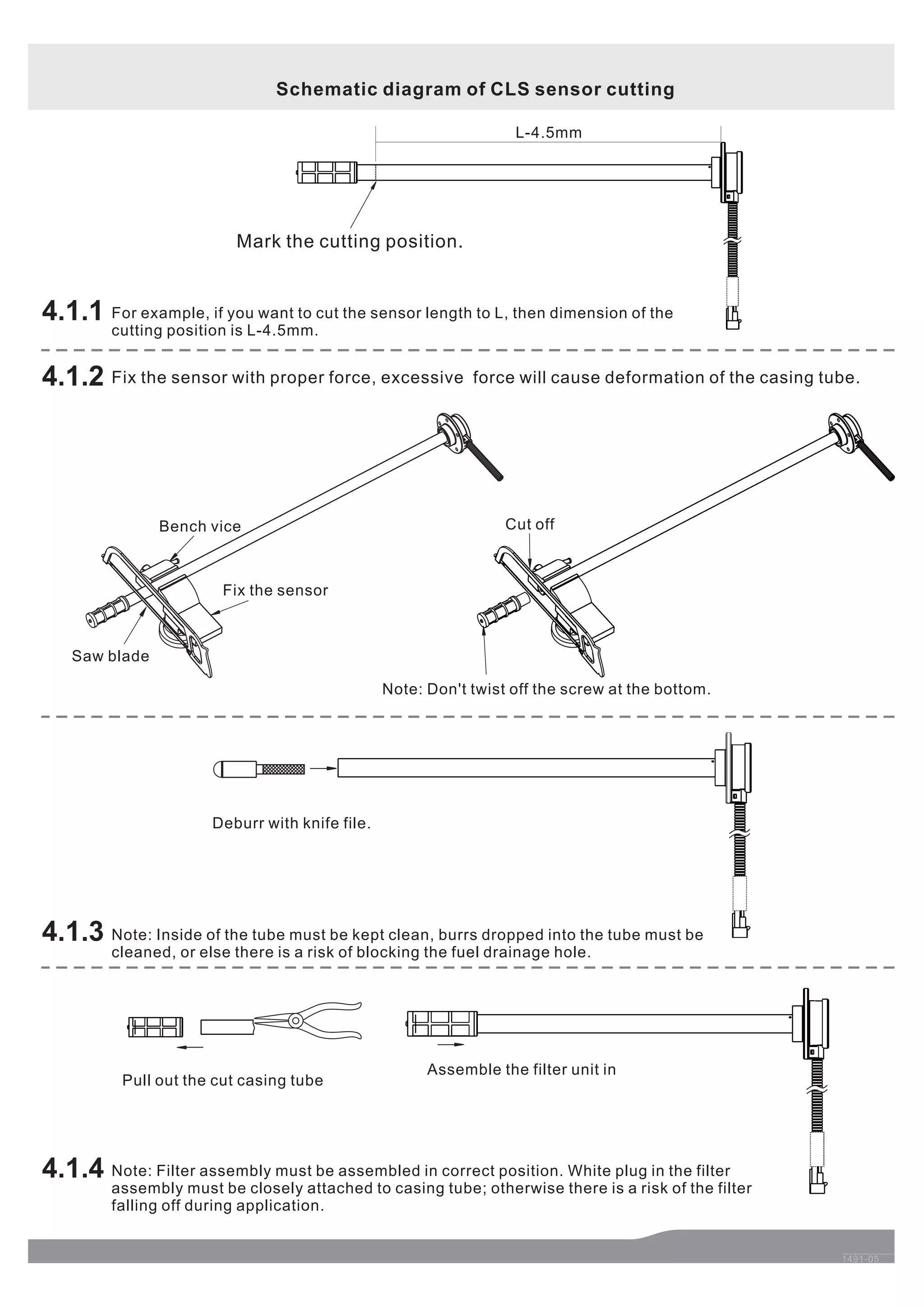

The document provides installation instructions for the CLS sensor series, which uses capacitance to detect fuel levels with a resolution of less than 1mm and can be trimmed to fit various tank heights. It includes technical specifications, connection modes, and detailed calibration procedures to ensure accurate measurements for different fuel types. The sensor operates within a wide temperature range and is compatible with various fuels, making it suitable for GPS fuel tracking applications.