camlift-hydraulic-pumping-unit-ps

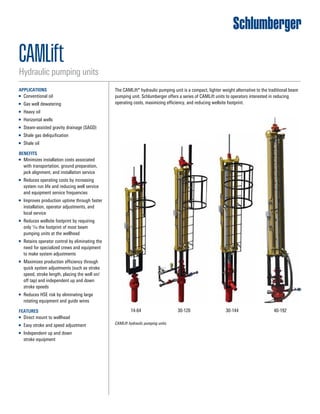

- 1. CAMLift hydraulic pumping units. 14-64 30-120 30-144 40-192 CAMLIFT Linear Lifting System CAMLIFT 14-64 CAMLIFT 30-120 CAMLIFT 30-144 CAMLIFT Cameron’s CAMLIFT Linear Lifting Systems As a compact, lighter weight alternative to the traditional beam pumping unit, Cameron offers a series of CAMLIFT™ linear lifting systems to operators interested in: • Minimizing installation costs • Reducing operating costs • Improving production efficiency • Eliminating ground site preparation and installation time • The efficient design of these CAMLIFTs uses le the footprint of a conventional pumping unit • Maximizing production efficiency as a result o to quickly complete adjustments (such as stro stroke length, placing the well on/off tap) • Retaining operator control as the need for sp crews and equipment to make system adjustm eliminated CAMLIFT Linear Lifting System CAMLIFT 14-64 CAMLIFT 30-120 CAMLIFT 30-144 CAMLIFT 40 Cameron’s CAMLIFT Linear Lifting Systems As a compact, lighter weight alternative to the traditional beam pumping unit, Cameron offers a series of CAMLIFT™ linear lifting systems to operators interested in: • Minimizing installation costs • Reducing operating costs • Improving production efficiency • Eliminating ground site preparation and installation time • The efficient design of these CAMLIFTs uses less t the footprint of a conventional pumping unit • Maximizing production efficiency as a result of th to quickly complete adjustments (such as stroke s stroke length, placing the well on/off tap) • Retaining operator control as the need for specia crews and equipment to make system adjustmen eliminated CAMLIFT Linear Lifting System CAMLIFT 14-64 CAMLIFT 30-120 CAMLIFT 30-144 CAMLIFT 40-192 Cameron’s CAMLIFT Linear Lifting Systems As a compact, lighter weight alternative to the traditional beam pumping unit, Cameron offers a series of CAMLIFT™ linear lifting systems to operators interested in: • Minimizing installation costs • Reducing operating costs • Improving production efficiency • Eliminating ground site preparation and installation time • The efficient design of these CAMLIFTs uses less than 1/10 the footprint of a conventional pumping unit • Maximizing production efficiency as a result of the ability to quickly complete adjustments (such as stroke speed, stroke length, placing the well on/off tap) • Retaining operator control as the need for specialized crews and equipment to make system adjustments is eliminated CAMLIFT Linear Lifting System CAMLIFT 14-64 CAMLIFT 30-120 CAMLIFT 30-144 CAMLIFT 40-192 Cameron’s CAMLIFT Linear Lifting Systems As a compact, lighter weight alternative to the traditional beam pumping unit, Cameron offers a series of CAMLIFT™ linear lifting systems to operators interested in: • Minimizing installation costs • Reducing operating costs • Improving production efficiency • Eliminating ground site preparation and installation time • The efficient design of these CAMLIFTs uses less than 1/10 the footprint of a conventional pumping unit • Maximizing production efficiency as a result of the ability to quickly complete adjustments (such as stroke speed, stroke length, placing the well on/off tap) • Retaining operator control as the need for specialized crews and equipment to make system adjustments is eliminated The CAMLift* hydraulic pumping unit is a compact, lighter weight alternative to the traditional beam pumping unit. Schlumberger offers a series of CAMLift units to operators interested in reducing operating costs, maximizing efficiency, and reducing wellsite footprint. APPLICATIONS ■■ Conventional oil ■■ Gas well dewatering ■■ Heavy oil ■■ Horizontal wells ■■ Steam-assisted gravity drainage (SAGD) ■■ Shale gas deliquification ■■ Shale oil BENEFITS ■■ Minimizes installation costs associated with transportation, ground preparation, jack alignment, and installation service ■■ Reduces operating costs by increasing system run life and reducing well service and equipment service frequencies ■■ Improves production uptime through faster installation, operator adjustments, and local service ■■ Reduces wellsite footprint by requiring only 1/10 the footprint of most beam pumping units at the wellhead ■■ Retains operator control by eliminating the need for specialized crews and equipment to make system adjustments ■■ Maximizes production efficiency through quick system adjustments (such as stroke speed, stroke length, placing the well on/ off tap) and independent up and down stroke speeds ■■ Reduces HSE risk by eliminating large rotating equipment and guide wires FEATURES ■■ Direct mount to wellhead ■■ Easy stroke and speed adjustment ■■ Independent up and down stroke equipment CAMLift Hydraulic pumping units

- 2. *Mark of Schlumberger Copyright © 2016 Schlumberger. All rights reserved. 16-AL-139851 CAMLift slb.com/rodlift CAMLift Hydraulic Pumping Unit Specifications 14-64 30-120 CamLift 30-144 CamLift 40-192 Applications Shallow gas/coalbed methane dewatering Light or medium crude Light to heavy crude Dewatering natural gas and coalbed methane Light to heavy crude Dewatering natural gas and coalbed methane Horizontal completions Light to heavy crude High volume Depths to 13,000 ft Horizontal completions Vertical, slant, or deviated well application Lift capacity, lbm 14,000 30,000 30,000 40,000 Max. stroke length, in 64 120 144 192 Max. speed†, strokes per minute 8 5.5 5.5 6.5 Min. speed†, strokes per minute 0.5 0.5 0.5 1.5 Jack dimensions (L×W×H) 20” × 18”× 7’5” 49”× 30”× 12’4” 49”× 30”× 14’4” 51”× 31”× 19’9” Jack shipping weight, lbm 675 1100 1250 2250 Skid dimenstions (L×W×H), 9’7”× 3’10”× 8’ 9’7”× 3’10”× 8’ 9’7”× 3’10”× 8’ 13’× 8’× 7’3” Skid shipping weight, lbm 3,300 3,300 3,300 12,000 Installation time, h <3 <3 <3 <6 Replaces 114s 80s 57s 456s 320s 228s 456s 320s 228s PCPs 912s 640s 456s ESPs PCPs † Maximum speed is dependent on many variables. Please review application with us for accurate production range. Conventional Pumping Units vs. CAMLift Hydraulic Pumping Units Conventional Units CAMLift Hydraulic Pumping Unit Ships in 1 to 3 trailer loads, depending on size Ship up to four units on one trailer Site preparation with gravel, concrete slab, and piles No mandatory site preparation, bolts directly to the wellhead; skid fully contained Installs in 2–5 days Installs in 6 hours Footprint of 10 ft × 10 ft or larger Minimal footprint next to well Installation and all adjustments require special crew, cranes, pickers Simple installation process, operators can make speed and stroke length adjustments Requires VFD for production optimization Independent up and down stroke speeds to allow for optimization Takes hours to treat gas lock— shutting down production Taps well in seconds to clear gas lock with no production downtime Requires crane to remove pump that is on tap, leading to premature pump failure Operator can take pump off tap with no production downtime All limitations for oil production are the same for dewatering All benefits on oil production are the same for dewatering Key Features 320-256-120 30-120 Lift capacity, lbm 25,600 30,000 Stroke length, in 90, 105, 120 40 to 120 Dimensions (L × W × H) 33.3 ft × 7.6 ft × 25 ft 49”× 30”× 12’4” Total weight, lbm 32,550 4,350 Footprint, ft 22 × 7 N/A (bolts to wellhead) Drawn to scale.