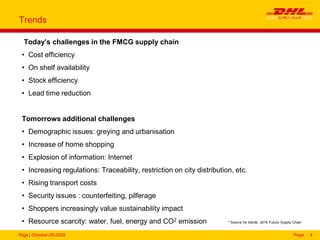

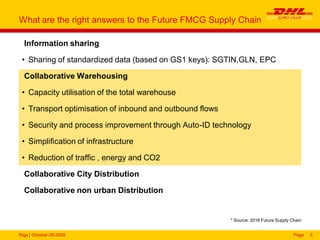

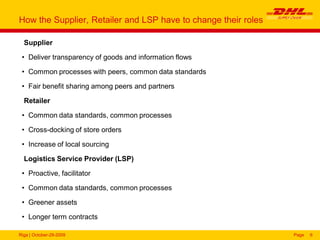

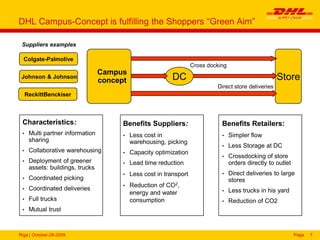

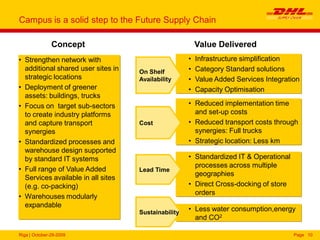

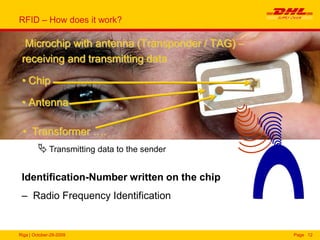

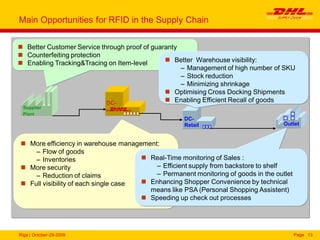

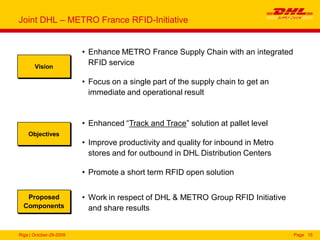

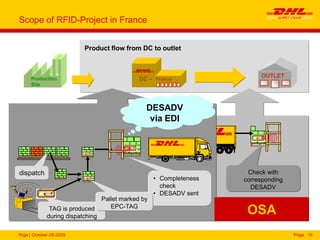

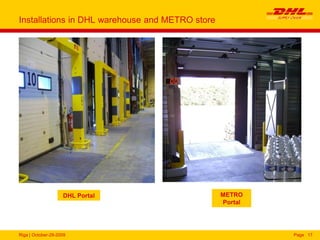

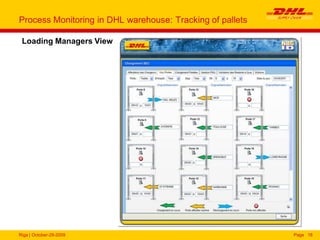

This document discusses steps towards improving future supply chain collaboration. It describes a DHL campus concept where suppliers collaborate on warehousing and deliveries, reducing costs and environmental impact. RFID technology is also discussed as another way to enhance supply chain visibility and efficiency, with an example of DHL and Metro implementing RFID tracking of pallets between DCs and stores in France. The document provides details on trends challenging supply chains and how information sharing, collaborative warehousing and distribution can help address these issues.