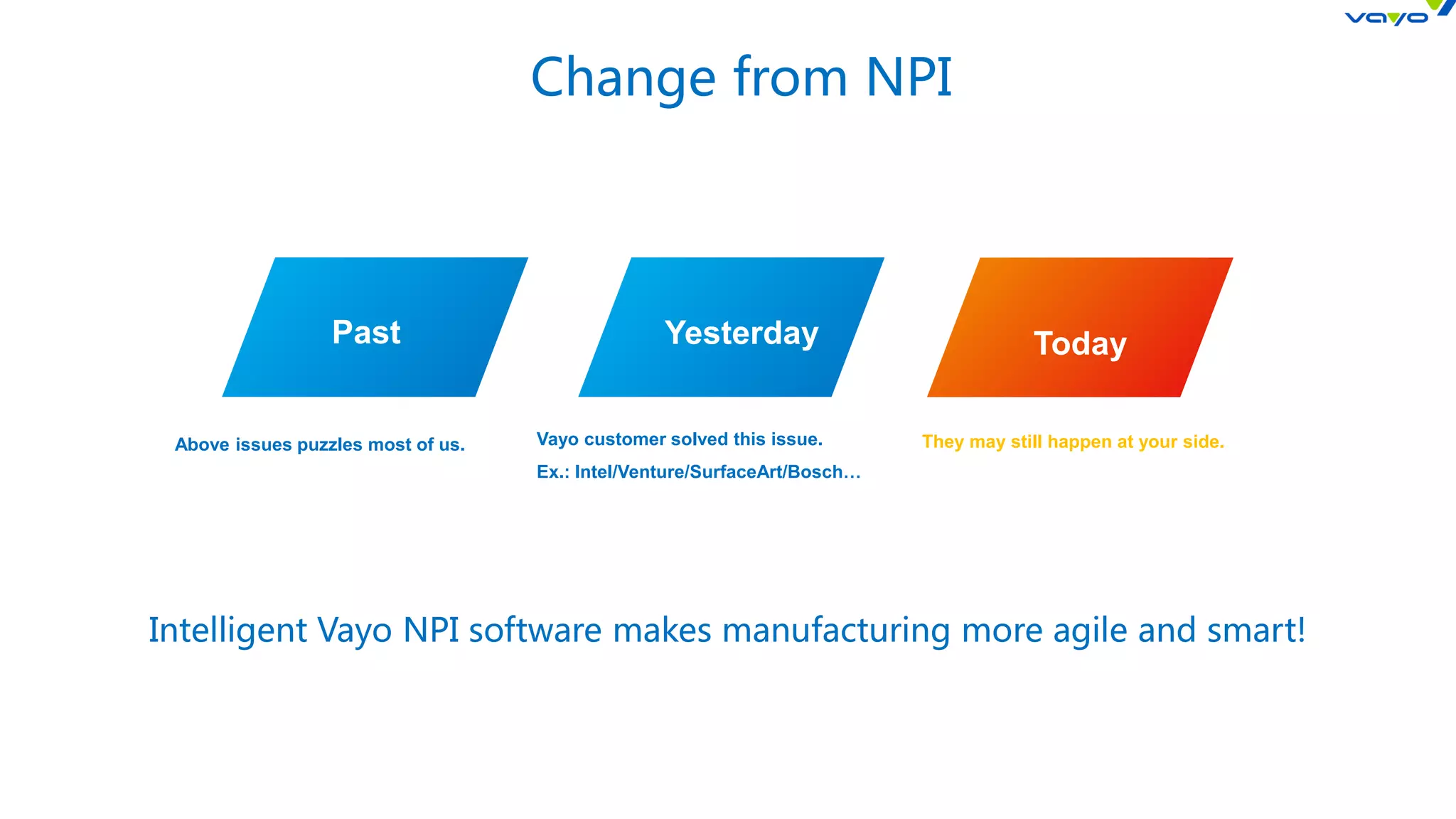

Vayo is a company that specializes in intelligent new product introduction (NPI) software aimed at enhancing design and manufacturing processes for printed circuit board assemblies (PCBAs). The software addresses common industry defects and inefficiencies, boasting significant improvements in quality, reliability, cycle time, and cost reduction for its users. With over 20 years of experience and installations in more than 20 countries, Vayo aims to make manufacturing more agile and efficient.