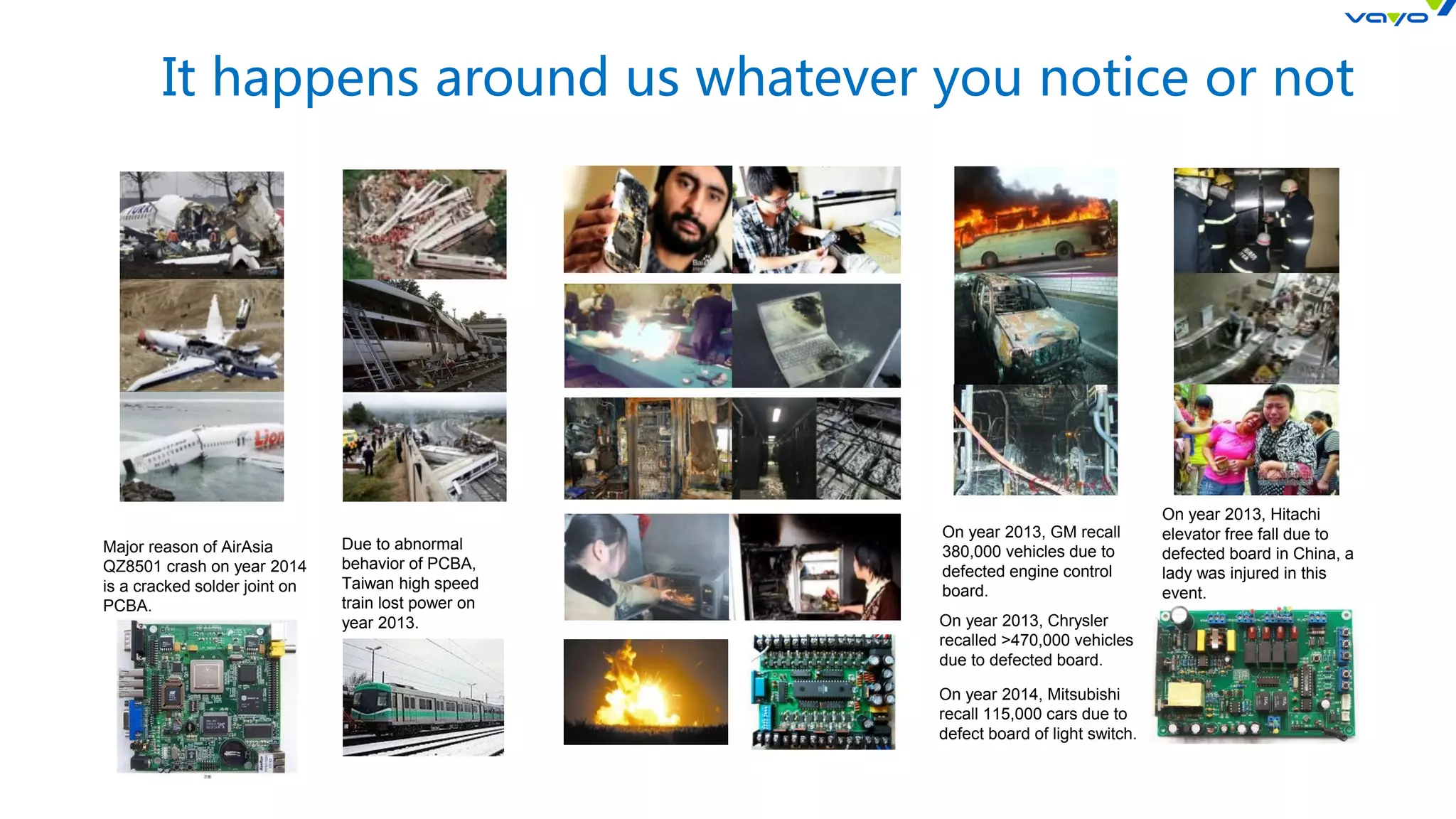

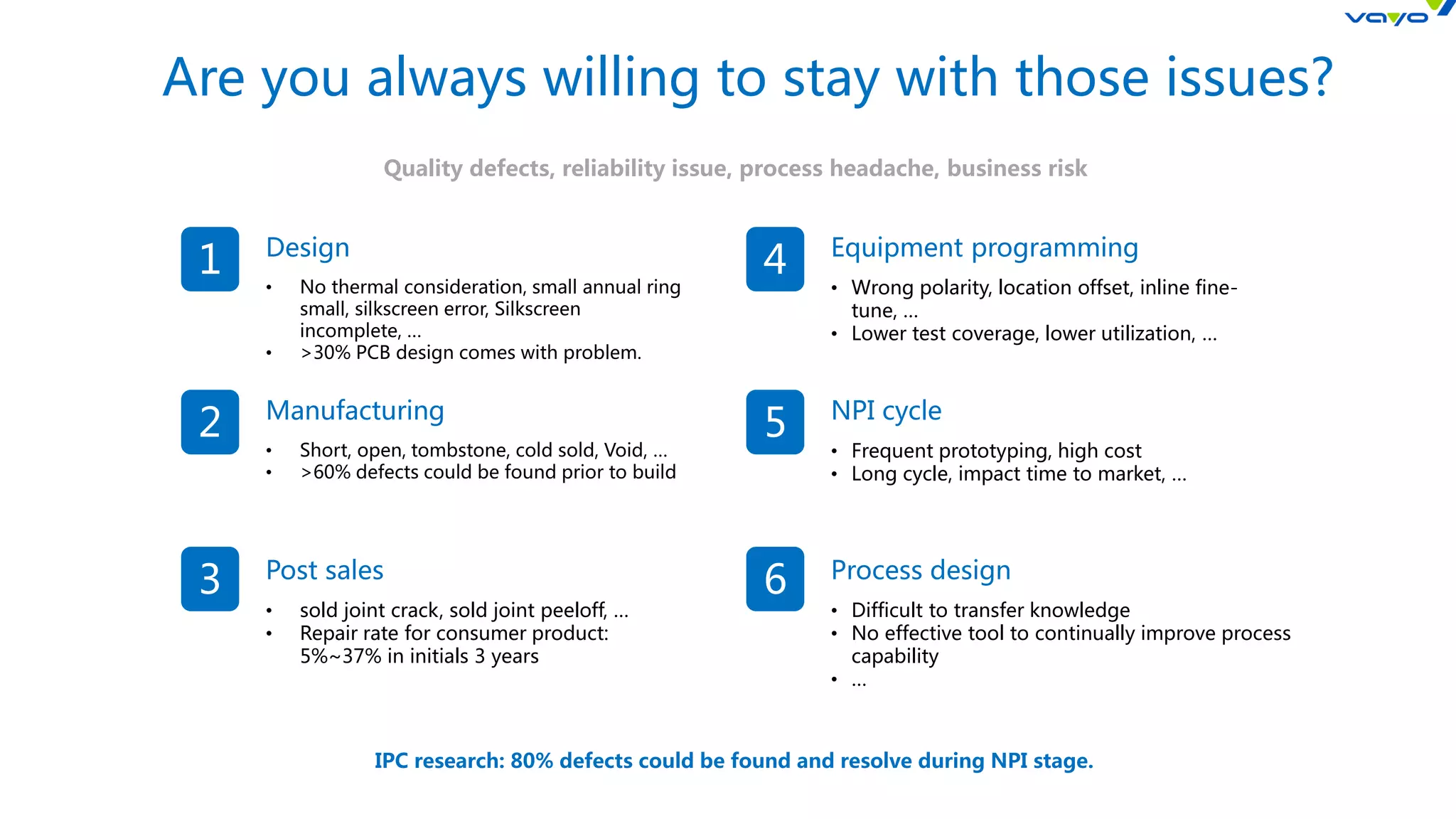

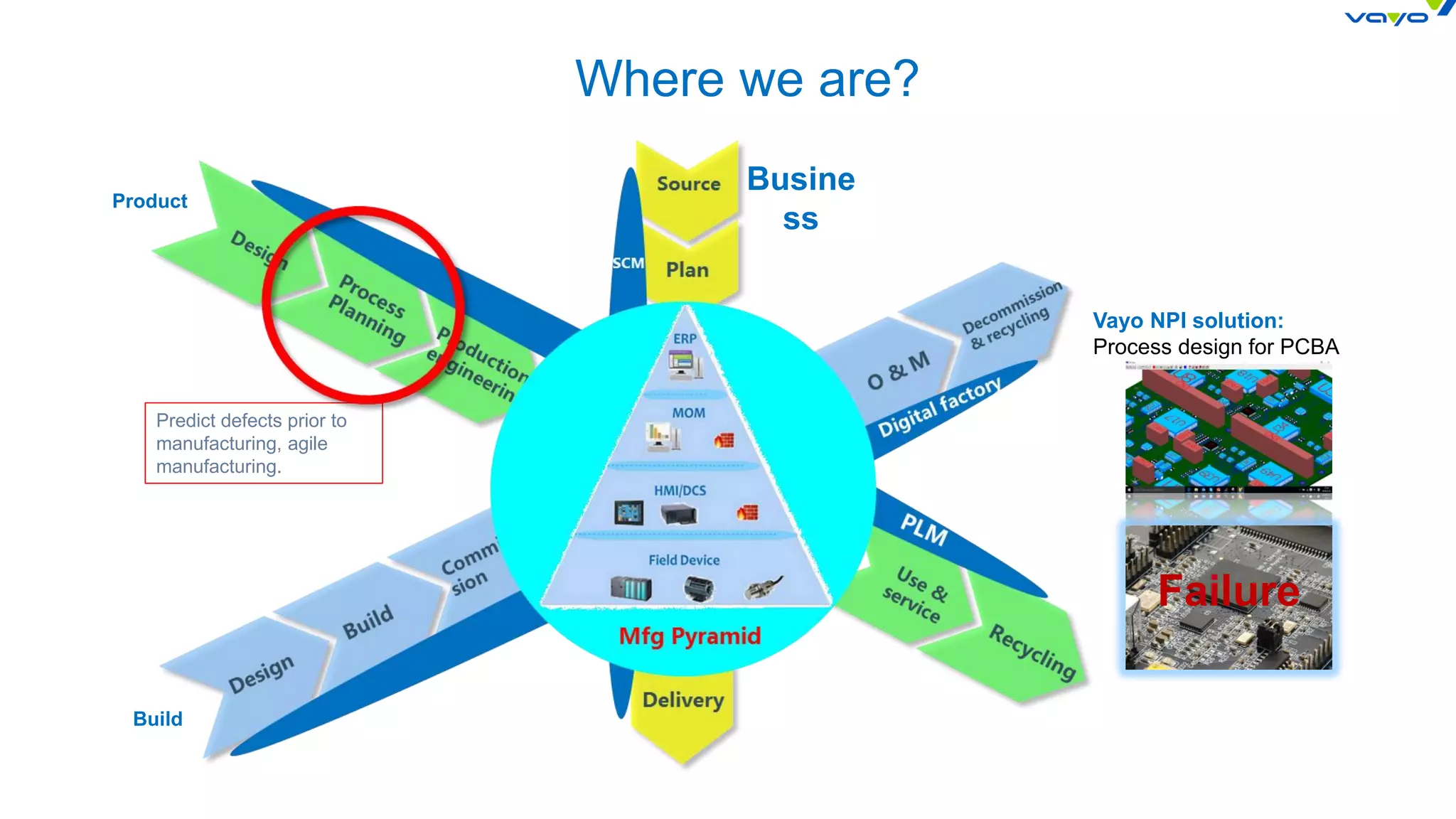

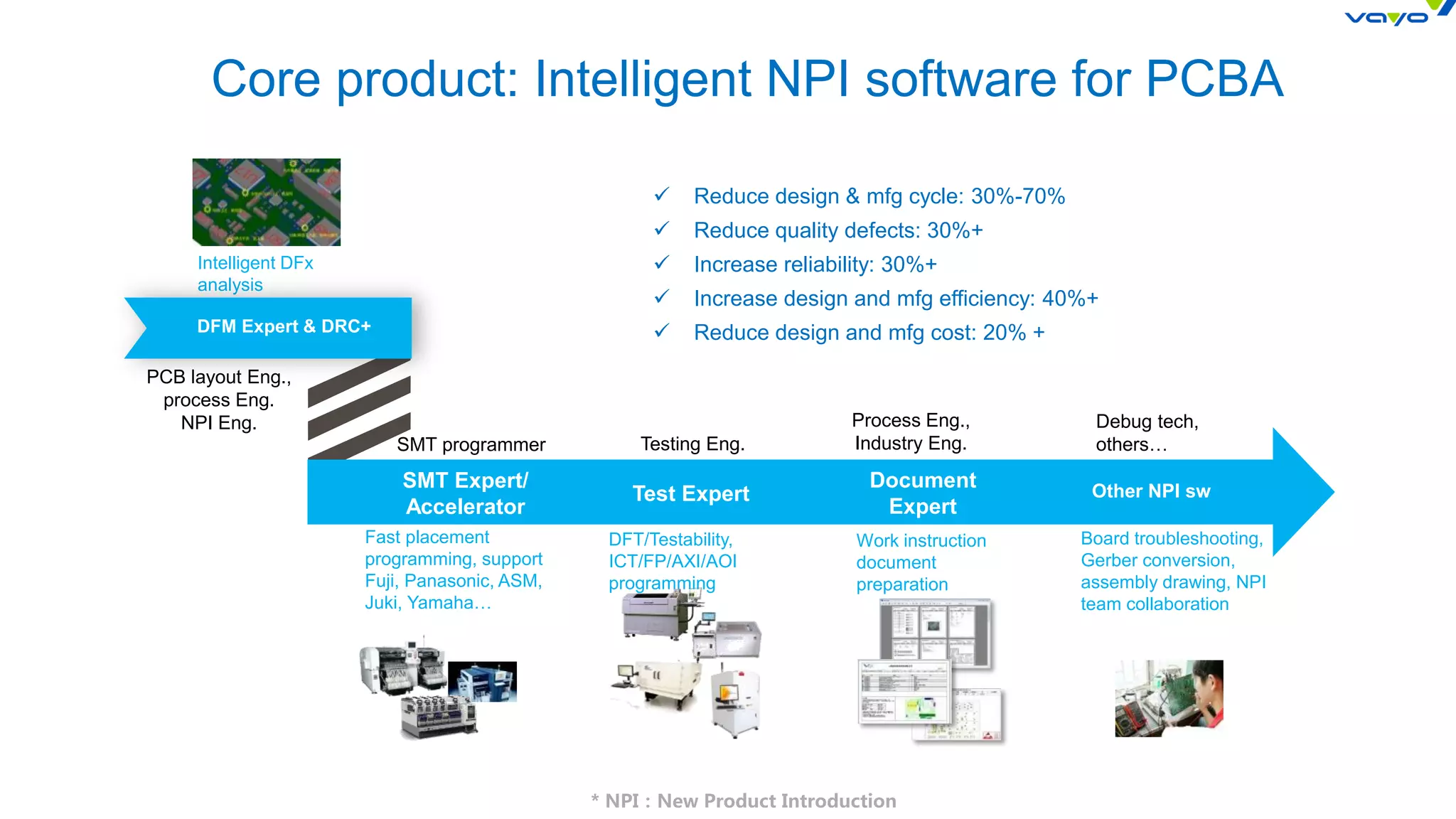

The document highlights the importance of intelligent software in the New Product Introduction (NPI) process for PCBA, addressing key issues such as defects in designs and manufacturing that have led to significant recalls and accidents in various industries. It emphasizes the potential of Vayo's NPI solutions to predict defects before manufacturing, thereby improving quality, reliability, and efficiency while reducing costs. Additionally, the report notes that over 80% of defects can be identified and resolved during the NPI stage.