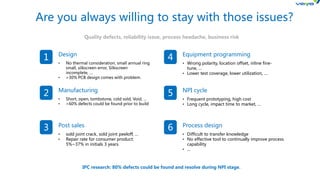

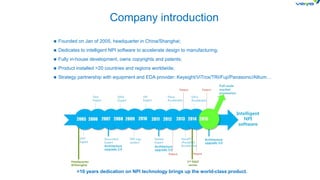

Vayo offers intelligent software solutions aimed at improving the design and manufacturing processes for New Product Introduction (NPI), specifically in the context of Industry 4.0 and IoT. Their tools address various manufacturing defects and inefficiencies, claiming significant reductions in design and manufacturing cycles, quality defects, and costs. Established in 2005, Vayo has a global presence with partnerships in over 20 countries, focusing on accelerating the transition from design to production.