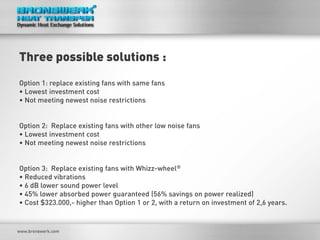

The document discusses dynamic solutions in process equipment, focusing on innovations by Bronswerk, including the Whizz-Wheel® fan, which offers significant noise reduction and energy efficiency benefits. It presents two case studies: one on debottlenecking a waste-to-energy plant in Germany that improved capacity and reduced noise, and another on upgrading a power plant in France that proposed a combination of higher air flow fans and adiabatic cooling for efficiency. Additional services provided by Bronswerk include site surveys and installation cleaning to enhance performance.