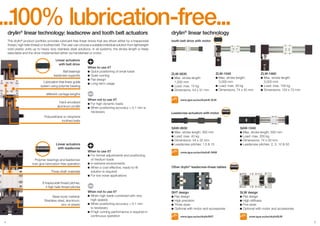

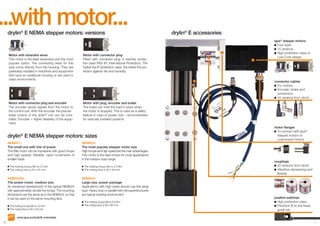

The document details igus®'s drylin® e lubrication-free linear actuator product line, highlighting various application examples and components including motor options, drive systems, and accessories. The system ensures clean, maintenance-free operation suitable for diverse applications such as camera adjustments and sensor configurations. It also features a customizable online ordering system for various actuator sizes and specifications.