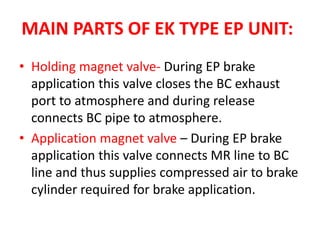

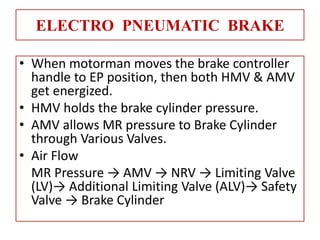

The document outlines the brake systems in AC Electric Multiple Units (EMU), detailing types of brakes such as electro-pneumatic, automatic, emergency, and parking brakes. It describes the components involved in the braking mechanisms, including various valves and controllers, as well as their functions during application and release. Additionally, the workings of the parking brake and its operation during standstill conditions are explained, emphasizing the importance of air pressure in the system.