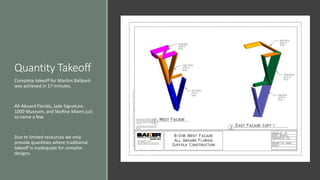

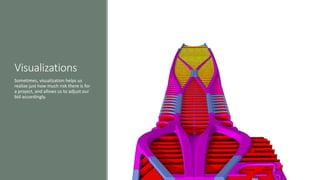

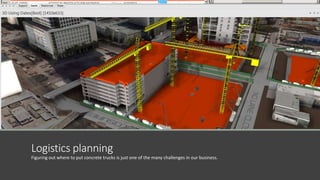

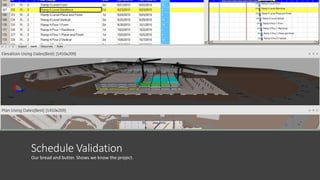

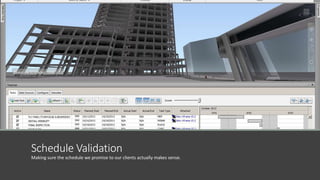

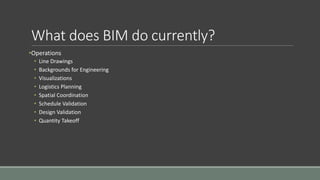

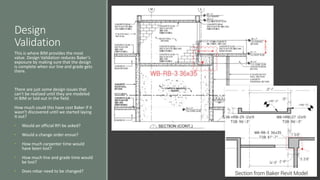

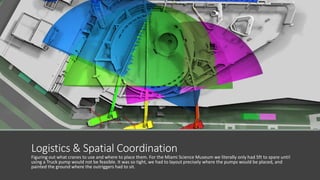

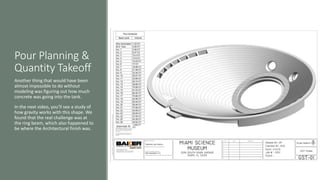

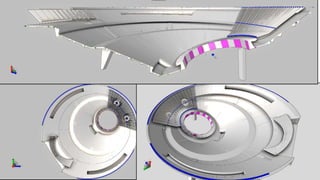

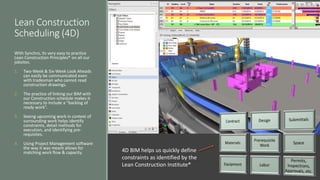

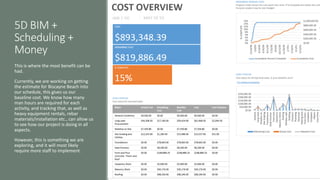

BIM provides many benefits for construction projects including quicker and more accurate quantity takeoffs, visualizations for design validation and client communication, and virtual rehearsals through 4D scheduling integration. It allows issues to be identified earlier in the design process, minimizing changes and rework. Specific examples are given of projects where BIM helped optimize logistics planning, pour planning, and schedule validation. Further benefits could be realized through expanded use of BIM for engineering support, line and grade automation, and 5D cost integration. However, additional resources and training would be required to fully implement these capabilities.