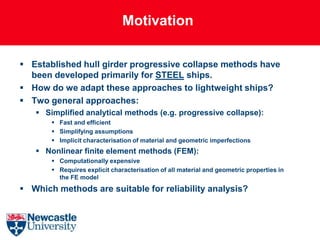

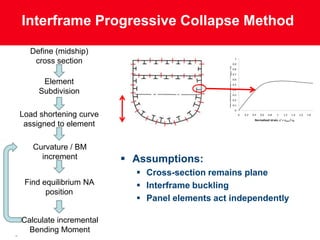

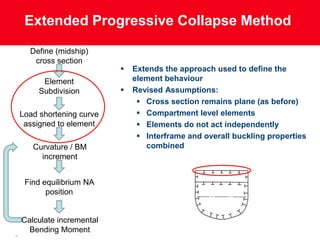

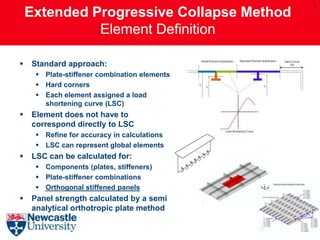

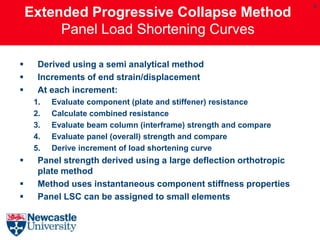

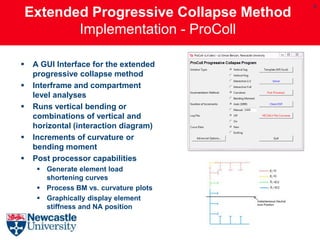

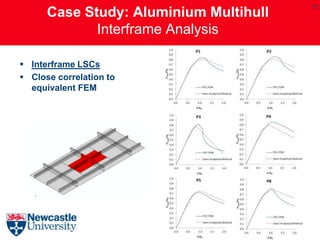

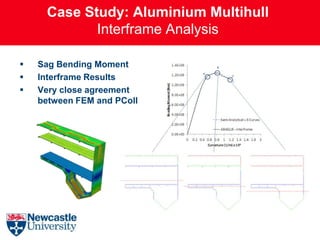

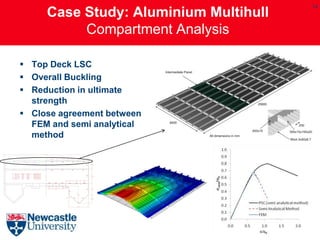

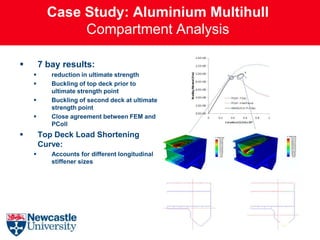

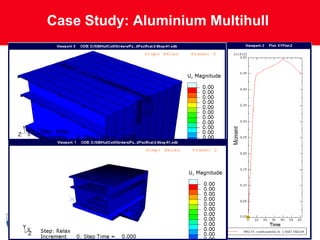

This document describes the development and extension of hull girder progressive collapse analysis methods for lightweight naval vessels. It presents the Smith Progressive Collapse Method and introduces the Extended Progressive Collapse Method, which adapts the approach to consider compartment-level elements rather than assuming independent interframe behavior. A case study analysis of an aluminum multihull vessel's longitudinal bending capacity is performed using the extended method and compared to nonlinear finite element analysis results, showing close agreement. The extended method and its ProColl implementation provide a simplified but accurate means of assessing the ultimate strength and collapse behavior of lightweight hull structures.